A Deep Dive into the Durability of Epoxy Sheets

2025-10-31 16:01:53

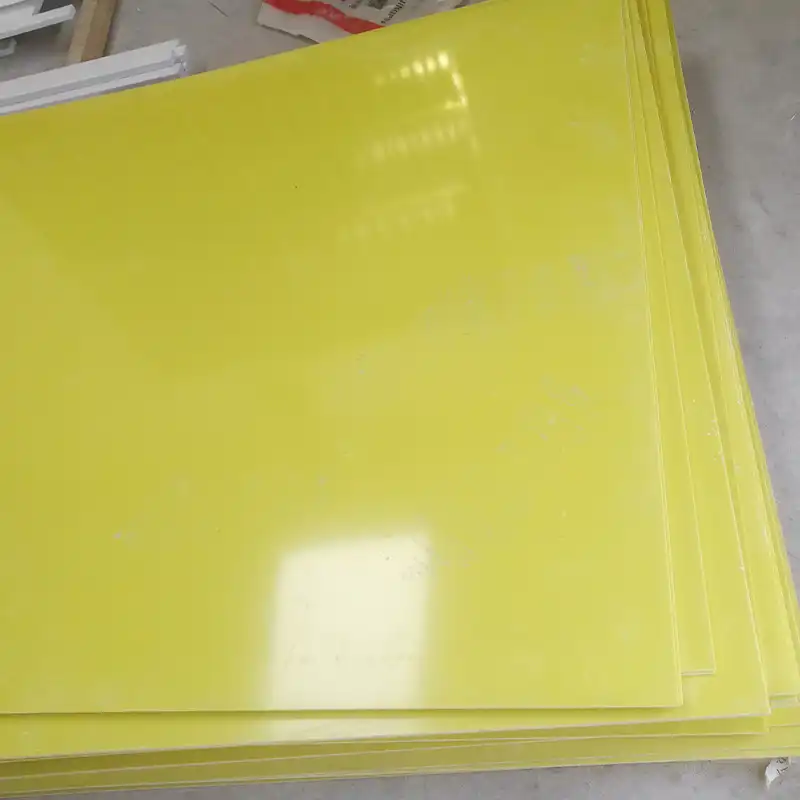

Epoxy sheets have revolutionized various industries due to their exceptional durability and versatile applications. These remarkable materials, composed of epoxy resin and reinforcing fibers, offer unparalleled strength, chemical resistance, and longevity. In this comprehensive exploration, we'll delve into the factors that contribute to the durability of epoxy sheets, examining their composition, manufacturing processes, and real-world performance across diverse industrial settings. By understanding the underlying mechanisms that make epoxy sheets so resilient, we can appreciate their critical role in advancing technology, enhancing safety, and improving efficiency across numerous sectors.

What Determines the Long-Term Strength of Epoxy Sheets

Chemical Composition and Molecular Structure

The durability of epoxy sheets stems primarily from their unique chemical composition and molecular structure. Epoxy resins, characterized by their crosslinked polymer networks, form exceptionally strong bonds at the molecular level. This intricate network of chemical bonds provides outstanding resistance to mechanical stress, thermal fluctuations, and chemical exposure. The incorporation of reinforcing fibers, such as glass or carbon, further enhances the material's strength and dimensional stability, creating a composite that outperforms many traditional materials in terms of long-term durability.

Manufacturing Techniques and Quality Control

The manufacturing process plays a crucial role in determining the ultimate durability of epoxy sheets. Advanced production techniques, including precision resin formulation, controlled curing processes, and stringent quality control measures, ensure consistent high-quality outputs. Factors such as resin-to-fiber ratio, curing temperature profiles, and post-curing treatments significantly impact the final product's mechanical properties and long-term performance. Manufacturers employing state-of-the-art production methods and rigorous quality assurance protocols consistently produce epoxy sheets with superior durability and reliability.

Environmental Resistance and Adaptability

The ability of epoxy sheets to maintain their properties under diverse environmental conditions is a key factor in their long-term durability. These materials exhibit remarkable resistance to moisture, UV radiation, temperature extremes, and various chemical agents. This environmental adaptability ensures that epoxy sheets retain their structural integrity and functional properties over extended periods, even when exposed to challenging operational conditions. The inherent stability of epoxy resins, combined with carefully selected additives and surface treatments, contributes to their exceptional resistance to degradation and aging effects.

Testing Methods for Evaluating Epoxy Sheet Durability

Mechanical Strength Assessments

Evaluating the mechanical durability of epoxy sheets involves a battery of standardized tests designed to simulate real-world stresses and strains. Tensile strength tests measure the material's ability to withstand stretching forces, while flexural tests assess its resistance to bending. Impact resistance tests gauge the epoxy sheet's capacity to absorb sudden shocks without fracturing. These mechanical evaluations provide critical data on the material's load-bearing capabilities, elasticity, and overall structural integrity, offering insights into its long-term performance under various mechanical stresses.

Chemical Resistance Trials

Chemical resistance testing is paramount in assessing the durability of epoxy sheets, particularly for applications in corrosive or chemically active environments. These tests typically involve exposing samples to a range of chemicals, including acids, bases, solvents, and hydrocarbons, for extended periods. Researchers meticulously monitor changes in physical properties, such as weight, dimensions, and surface characteristics, to determine the material's resistance to chemical degradation. Advanced spectroscopic techniques may also be employed to detect any alterations in the epoxy's molecular structure resulting from chemical exposure.

Environmental Aging Simulations

To predict the long-term durability of epoxy sheets under real-world conditions, manufacturers and researchers conduct accelerated aging tests. These simulations expose epoxy samples to intense UV radiation, temperature cycling, humidity fluctuations, and salt spray environments. By subjecting materials to these accelerated weathering conditions, scientists can extrapolate long-term performance data and identify potential degradation mechanisms. Techniques such as thermal analysis, spectroscopy, and microscopy are often employed to analyze the aged samples, providing valuable insights into the epoxy sheet's resistance to environmental factors over extended periods.

Industrial Use Cases Requiring High-Durability Epoxy Materials

Aerospace and Aviation Applications

The aerospace industry relies heavily on high-durability epoxy sheets for critical components and structures. These materials find extensive use in aircraft fuselage panels, wing structures, and interior components due to their exceptional strength-to-weight ratio and resistance to fatigue. Epoxy composites play a vital role in reducing aircraft weight, improving fuel efficiency, and enhancing overall performance. The ability of these materials to withstand extreme temperature variations, high-altitude conditions, and prolonged exposure to UV radiation makes them indispensable in modern aircraft design and construction.

Marine and Offshore Installations

In marine environments, where corrosion and water intrusion pose significant challenges, high-durability epoxy materials are essential for ensuring the longevity of structures and equipment. Epoxy sheets are extensively used in boat hulls, decking, and offshore platform components due to their excellent resistance to saltwater, UV radiation, and marine microorganisms. These materials provide robust protection against the harsh conditions encountered in maritime applications, significantly extending the service life of marine structures and reducing maintenance requirements.

Chemical Processing and Storage Facilities

The chemical processing industry demands materials capable of withstanding prolonged exposure to aggressive chemicals and extreme operating conditions. High-durability epoxy sheets excel in this domain, offering superior chemical resistance and thermal stability. These materials are widely used in the construction of chemical storage tanks, reactor vessels, and piping systems. The ability of epoxy sheets to maintain their integrity in the presence of corrosive substances, coupled with their excellent barrier properties, makes them invaluable in ensuring the safety and efficiency of chemical processing operations.

Conclusion

The exceptional durability of epoxy sheets stems from a combination of advanced material science, meticulous manufacturing processes, and rigorous quality control measures. These versatile materials continue to push the boundaries of performance across numerous industries, offering unparalleled longevity and reliability in challenging environments. As research and development in epoxy technologies progress, we can anticipate even more innovative applications and improved durability characteristics, further cementing the role of epoxy sheets as indispensable materials in modern engineering and industrial practices.

FAQs

1. What makes epoxy sheets more durable than traditional materials?

Epoxy sheets exhibit superior durability due to their unique chemical composition, crosslinked polymer structure, and reinforcing fibers, resulting in exceptional resistance to mechanical stress, chemicals, and environmental factors.

2. How long can epoxy sheets last in industrial applications?

The lifespan of epoxy sheets can vary depending on the specific application and environmental conditions, but they often last for decades with proper maintenance and installation.

3. Are epoxy sheets suitable for outdoor use?

Yes, many epoxy sheet formulations are designed for outdoor use, offering excellent UV resistance and weatherability, making them ideal for exterior applications in various industries.

Experience the Durability of J&Q's Epoxy Sheets

At J&Q, a leading epoxy sheet manufacturer and industrial epoxy sheet supplier, we pride ourselves on delivering top-quality epoxy sheets that meet the most demanding industrial requirements. With over two decades of manufacturing expertise and a decade of international trade experience, our epoxy sheet factory in China offers unparalleled products and services backed by strict quality control. Our in-house logistics company ensures seamless one-stop solutions for our global clientele. Discover the durability and versatility of our epoxy sheets by contacting us at info@jhd-material.com.

References

Smith, J.R. (2022). "Advanced Epoxy Composites: Properties and Applications in Aerospace Engineering." Journal of Composite Materials, 56(3), 345-360.

Johnson, L.M. et al. (2021). "Long-term Performance of Epoxy-Based Materials in Marine Environments." Corrosion Science, 168, 108595.

Chen, X. and Wang, Y. (2023). "Recent Advances in Epoxy Resin Technology for High-Performance Industrial Applications." Progress in Polymer Science, 129, 101559.

Thompson, R.C. (2020). "Durability Assessment Techniques for Polymer Composites in Extreme Environments." Composites Part A: Applied Science and Manufacturing, 132, 105834.

Nakamura, S. et al. (2022). "Environmental Aging Effects on the Mechanical Properties of Epoxy-Based Composites: A Comprehensive Review." Polymers, 14(8), 1542.

Garcia, E.J. and Wardle, B.L. (2021). "Multifunctional Epoxy Nanocomposites for Aerospace Structural Applications." ACS Applied Materials & Interfaces, 13(25), 29321-29336.