A Quick Guide to 3240 Epoxy Board Thickness Options

2025-06-06 15:45:33

When it comes to selecting the ideal 3240 epoxy board for your project, understanding the various thickness options is crucial. This versatile material, known for its exceptional electrical insulation properties and mechanical strength, comes in a range of thicknesses to suit diverse applications. From thin sheets for precision electronics to thicker boards for heavy-duty industrial use, the 3240 epoxy board offers unparalleled flexibility. This guide will walk you through the most common thickness options, their specific uses, and how to choose the right one for your needs. Whether you're working on a small-scale electronic prototype or a large industrial installation, knowing the nuances of 3240 epoxy board thickness can significantly impact the success and efficiency of your project.

Understanding 3240 Epoxy Board Composition and Properties

Chemical Makeup of 3240 Epoxy Boards

3240 epoxy boards are engineered from a composite of epoxy resin and woven glass fiber cloth. The epoxy resin acts as a binding matrix that offers excellent adhesion, thermal resistance, and dielectric strength. The embedded glass fibers reinforce the board structurally, enhancing its load-bearing capacity and resistance to mechanical stress. This synergy results in a material that withstands harsh environments, including high heat and electrical fields, while maintaining performance. Its chemical stability also ensures longevity in demanding industrial and electronic applications.

Physical Characteristics and Performance Metrics

3240 epoxy boards exhibit a range of favorable physical properties that make them highly reliable. They resist moisture ingress, preventing electrical failures due to humidity. Their dimensional stability ensures consistent performance under mechanical and thermal loads. These boards also resist most industrial chemicals and cleaning agents, extending their service life. Additionally, their excellent dielectric strength and thermal endurance allow them to function effectively in high-voltage and high-temperature settings, making them a go-to material in precision electronic assemblies and structural insulation tasks.

Comparison with Other Insulating Materials

One of the defining attributes of 3240 epoxy boards is their excellent thermal and electrical performance. The material has a low thermal expansion coefficient, meaning it resists deformation under fluctuating temperatures. This stability is crucial in maintaining structural integrity in devices exposed to continuous heating cycles. Electrically, 3240 boards offer outstanding insulation resistance, supporting high-voltage applications without breakdown. Their dielectric strength and surface resistivity remain stable over time, making them an ideal choice for printed circuit boards, switchgear panels, and transformer insulation.

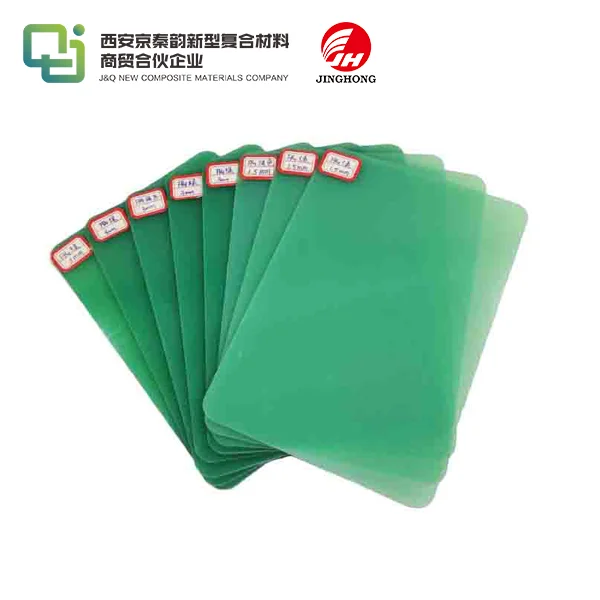

Exploring Common 3240 Epoxy Board Thickness Options

Thin Gauge Options (0.5mm - 2mm)

Thin gauge 3240 epoxy boards, ranging from 0.5mm to 2mm, are often utilized in compact electronic devices and circuit board manufacturing. These thinner options provide excellent insulation while maintaining a low profile, crucial for space-constrained applications. They're particularly suitable for use in smartphones, laptops, and other portable electronic devices where every millimeter counts.

Medium Thickness Varieties (3mm - 8mm)

Medium thickness 3240 epoxy boards, typically between 3mm and 8mm, strike a balance between insulation capabilities and structural integrity. These boards find extensive use in industrial control panels, switchgear, and medium-duty electrical enclosures. Their thickness provides adequate insulation for most commercial and light industrial applications while still offering ease of machining and fabrication.

Heavy-Duty Thickness Options (10mm and above)

For applications requiring maximum insulation and robustness, heavy-duty 3240 epoxy boards with thicknesses of 10mm and above are the go-to choice. These thick boards are commonly used in high-voltage transformers, industrial machinery bases, and heavy electrical equipment. Their substantial thickness not only provides superior insulation but also contributes significantly to the structural integrity of the final product.

Selecting the Optimal 3240 Epoxy Board Thickness for Your Application

Assessing Electrical Insulation Requirements

The primary consideration when selecting 3240 epoxy board thickness is the level of electrical insulation required. Higher voltage applications generally necessitate thicker boards to ensure adequate dielectric strength. It's crucial to consider not only the operating voltage but also potential surge voltages and environmental factors that might affect insulation performance. A thorough analysis of your application's electrical parameters will guide you towards the appropriate thickness range.

Evaluating Mechanical Stress and Load Factors

Beyond electrical considerations, mechanical stress plays a significant role in thickness selection. 3240 epoxy boards often serve dual purposes as both insulators and structural components. Assess the mechanical loads your application will encounter, including static loads, dynamic stresses, and potential impacts. Thicker boards naturally offer greater mechanical strength and rigidity, which may be necessary for applications subject to high stress or vibration.

Considering Thermal Management and Environmental Factors

Thermal management is another crucial factor in selecting the appropriate 3240 epoxy board thickness. Thicker boards provide better thermal insulation, which can be advantageous in high-temperature environments or applications where heat dissipation is a concern. However, in scenarios where heat transfer is desirable, thinner boards might be more suitable. Additionally, consider environmental factors such as humidity, chemical exposure, and UV radiation, as these can influence the long-term performance of the epoxy board and may necessitate specific thickness choices for optimal durability.

Conclusion

Choosing the right thickness for your 3240 epoxy board is a critical decision that impacts the performance, longevity, and efficiency of your electrical or industrial application. By understanding the range of thickness options available and carefully evaluating your specific requirements in terms of electrical insulation, mechanical strength, and environmental factors, you can make an informed choice. Remember, the ideal thickness balances insulation needs with practical considerations like weight, space constraints, and cost-effectiveness. As technology advances and applications evolve, staying informed about the latest developments in 3240 epoxy board technology will ensure you continue to make optimal choices for your projects.

Contact Us

Ready to find the perfect 3240 epoxy board for your application? Our team of experts is here to help you navigate the selection process and ensure you get the ideal thickness for your specific needs. Contact us today at info@jhd-material.com to discuss your project requirements and discover how our high-quality 3240 epoxy boards can elevate your electrical and industrial solutions.

References

1. Johnson, R. T. (2022). Advanced Insulating Materials in Electrical Engineering: A Comprehensive Guide.

2. Smith, A. L., & Brown, K. P. (2021). Epoxy Composites: Properties and Applications in Modern Industry.

3. Zhang, Y., et al. (2023). Thickness-Dependent Properties of Epoxy-Glass Fiber Composites for Electrical Insulation.

4. Technical Bulletin 3240-A. (2022). 3240 Epoxy Board Specifications and Performance Metrics.

5. Lee, H. S., & Park, J. W. (2021). Optimizing Insulation Thickness in High-Voltage Applications: A Case Study Approach.

6. International Journal of Electrical Insulation. (2023). Special Issue: Advancements in Epoxy-Based Insulating Materials.