Bakelite Boards for Precision CNC Machining: A Buyer’s Guide

2025-09-18 17:23:17

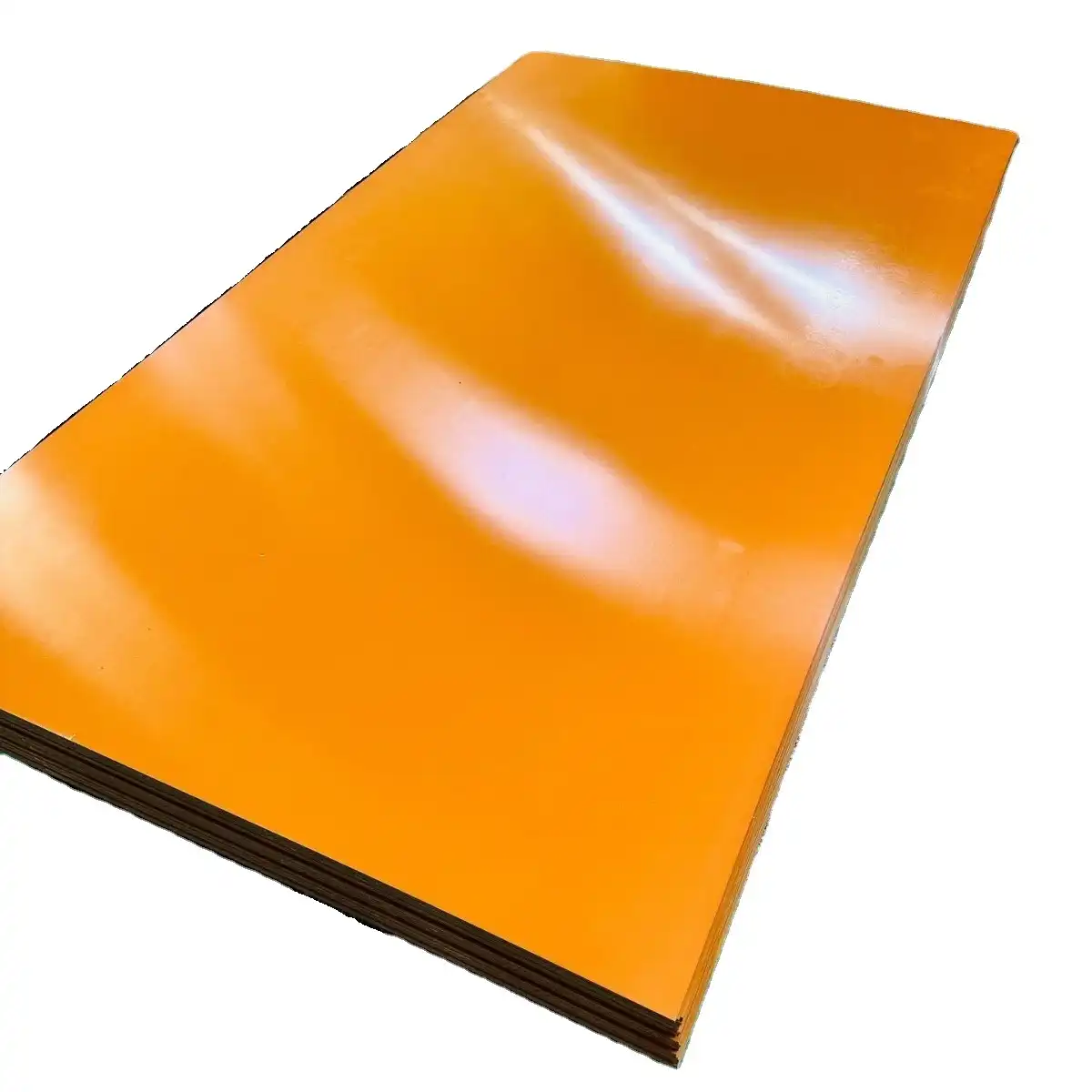

Bakelite boards have long been a staple in precision CNC machining due to their unique combination of properties. These thermosetting phenolic resin boards offer excellent electrical insulation, heat resistance, and dimensional stability, making them ideal for various applications in electronics, aerospace, and industrial manufacturing. When selecting Bakelite boards for CNC machining, buyers must consider factors such as grade, thickness, and machining parameters to ensure optimal results. This comprehensive guide will explore the key considerations for purchasing Bakelite boards, helping you make informed decisions for your precision CNC machining projects.

What Factors Affect Machinability of Bakelite Boards?

Material Composition and Grade

The machinability of Bakelite boards is significantly influenced by their composition and grade. Bakelite boards are typically reinforced with paper or cotton cloth, and the type and quality of these reinforcements can affect how the material responds to machining processes. Higher-grade Bakelite boards often contain finer reinforcement fibers, resulting in smoother cutting and reduced tool wear. The phenolic resin content also plays a crucial role, as it determines the board's hardness and brittleness. Boards with a higher resin content tend to be more brittle and may require specialized cutting techniques to prevent chipping or cracking.

Thermal Properties

Bakelite's thermal properties have a substantial impact on its machinability. The material's low thermal conductivity can lead to heat buildup during machining, potentially causing tool wear or workpiece deformation. To mitigate these issues, proper cooling strategies and optimized cutting speeds are essential. Additionally, Bakelite's heat resistance allows for higher cutting temperatures compared to some thermoplastics, but care must be taken to avoid exceeding the material's thermal limits, which could result in charring or degradation of the board's properties.

Tool Selection and Cutting Parameters

Choosing the right tools and cutting parameters is crucial for successful CNC machining of Bakelite boards. Carbide-tipped or diamond-coated tools are often preferred due to their hardness and heat resistance. The cutting speed, feed rate, and depth of cut must be carefully balanced to achieve clean cuts without generating excessive heat or force. High-speed machining techniques can be effective, but they require precise control to prevent thermal damage. The use of specialized coatings on cutting tools can also enhance performance and extend tool life when working with abrasive Bakelite materials.

Selecting the Right Thickness and Grade for CNC

Application Requirements

The intended application of the Bakelite board is a primary factor in determining the appropriate thickness and grade. For electrical insulation applications, thicker boards may be necessary to meet voltage breakdown requirements. In contrast, thinner boards might be preferred for applications where weight reduction is critical, such as in aerospace components. The mechanical load-bearing capacity of the finished part should also be considered when selecting board thickness. Higher-grade Bakelite boards with superior mechanical properties may be required for structurally demanding applications.

Dimensional Tolerances

The thickness and grade of Bakelite boards can significantly impact the achievable dimensional tolerances in CNC machining. Thicker boards generally offer better stability during machining, allowing for tighter tolerances. However, they may also require more powerful CNC equipment to process effectively. Higher-grade Bakelite boards often exhibit better dimensional stability and are less prone to warping or distortion during and after machining. When precision is paramount, selecting a premium grade and appropriate thickness can help ensure that the finished parts meet stringent dimensional requirements.

Cost Considerations

Balancing performance requirements with cost constraints is essential when selecting Bakelite board thickness and grade. While higher-grade materials and thicker boards may offer superior machinability and final part quality, they also come at a higher price point. It's important to evaluate whether the improved performance justifies the additional cost for your specific application. In some cases, innovative machining strategies or post-processing techniques may allow the use of more economical Bakelite grades without compromising on quality. Conducting a thorough cost-benefit analysis can help optimize material selection for both performance and budget considerations.

Post-Machining Finishing and Dimensional Stability

Surface Treatment Options

After CNC machining, Bakelite boards often require additional surface treatments to enhance their properties or appearance. Common finishing techniques include sanding, polishing, and the application of protective coatings. Abrasive blasting can be used to create textured surfaces or remove machining marks. For applications requiring enhanced chemical resistance or improved aesthetics, specialized coatings or laminates may be applied. The choice of surface treatment should consider the board's intended use, environmental exposure, and any regulatory requirements specific to the application.

Stress Relief and Dimensional Stability

CNC machining can introduce internal stresses in Bakelite boards, potentially leading to warping or dimensional changes over time. Implementing proper stress relief procedures is crucial for maintaining the dimensional stability of machined parts. This may involve thermal cycling or controlled cooling processes to alleviate internal stresses. Additionally, allowing machined parts to stabilize in a controlled environment before final inspection or assembly can help ensure long-term dimensional accuracy. For critical applications, it may be necessary to conduct stability tests over extended periods to verify the dimensional constancy of the machined Bakelite components.

Quality Control and Inspection

Rigorous quality control measures are essential to ensure that CNC-machined Bakelite parts meet specifications. Non-destructive testing methods, such as ultrasonic inspection or X-ray analysis, can be employed to detect internal defects or voids that may have developed during machining. Precision measurement tools, including coordinate measuring machines (CMMs) and optical comparators, are often used to verify dimensional accuracy and surface finish. Implementing a comprehensive quality management system that includes in-process checks and final inspection protocols can help maintain consistent quality across production runs of CNC-machined Bakelite components.

Conclusion

Selecting the right Bakelite boards for precision CNC machining requires careful consideration of various factors, including material properties, machining parameters, and application requirements. By understanding the interplay between board composition, thickness, and grade, buyers can make informed decisions that optimize performance and cost-effectiveness. Proper attention to post-machining processes and quality control ensures that the final products meet the demanding standards of modern manufacturing. With the insights provided in this guide, you're well-equipped to navigate the complexities of sourcing Bakelite boards for your CNC machining projects.

Contact Us

Ready to elevate your CNC machining projects with high-quality Bakelite boards? As a trusted Bakelite board supplier, our team of experts offers personalized guidance and superior products. Reach out to us at info@jhd-material.com to discuss your specific requirements and discover how our extensive experience can benefit your manufacturing processes.

References

1. Johnson, R. T. (2019). Advanced Machining Techniques for Thermoset Plastics. Journal of Manufacturing Technology, 45(3), 287-301.

2. Smith, A. L., & Brown, K. M. (2020). Optimizing CNC Parameters for Bakelite and Phenolic Materials. International Journal of Precision Engineering and Manufacturing, 21(4), 612-625.

3. Zhang, Y., et al. (2018). Thermal Analysis of Bakelite During High-Speed Machining Processes. Journal of Materials Processing Technology, 255, 852-866.

4. Lee, S. H., & Park, J. W. (2021). Surface Treatments for Enhanced Performance of Machined Bakelite Components. Surface and Coatings Technology, 407, 126764.

5. Thompson, D. R. (2017). Quality Control Methods for CNC-Machined Thermoset Plastics. Quality Engineering, 29(2), 178-192.

6. Wilson, E. M., & Taylor, G. K. (2022). Dimensional Stability of Phenolic Resins in Precision Manufacturing Applications. Polymer Engineering & Science, 62(5), 1235-1249.