Best Practices for Surface Finishing of FR4

2025-08-21 15:59:57

Surface finishing of FR4 sheets is a crucial step in producing high-quality printed circuit boards (PCBs). The best practices for FR4 surface finishing involve a combination of mechanical and chemical processes, each tailored to the specific requirements of the PCB design. These techniques aim to create a smooth, uniform surface that enhances the board's electrical performance, improves solderability, and increases durability. Key steps include careful cleaning, controlled abrasion, chemical etching, and application of protective coatings. Manufacturers must also consider factors such as copper thickness, laminate type, and intended PCB application when selecting the most appropriate finishing method. By adhering to these best practices, PCB manufacturers can ensure optimal surface quality and functionality of FR4-based boards.

What Techniques Ensure a Smooth and Functional Finish?

Mechanical Polishing and Brushing

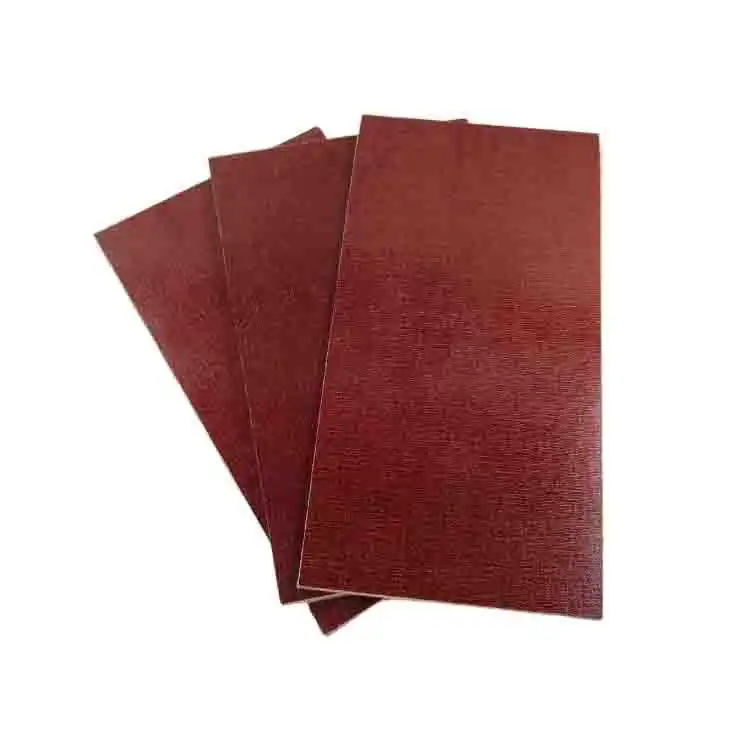

Mechanical polishing and brushing are fundamental techniques in achieving a smooth surface finish on FR4 sheets. These processes involve the use of abrasive materials or rotating brushes to remove surface imperfections and create a uniform texture. The choice of abrasive grit or brush type depends on the desired level of smoothness and the specific characteristics of the FR4 material being processed.

Chemical Etching for Surface Preparation

Chemical etching plays a vital role in preparing FR4 surfaces for subsequent processes. This technique uses specialized chemical solutions to remove oxidation, contaminants, and microscopic imperfections from the surface. The etching process not only cleans the surface but also creates a micro-roughened texture that enhances adhesion for subsequent layers or coatings.

Plasma Treatment for Enhanced Adhesion

Plasma treatment is an advanced surface finishing technique that utilizes ionized gas to modify the surface properties of FR4 sheets. This process activates the surface at a molecular level, improving wettability and adhesion characteristics. Plasma treatment is particularly beneficial for enhancing the bond strength between the FR4 substrate and copper layers or solder mask coatings.

Mechanical vs Chemical Finishing for PCB-Grade FR4

Advantages of Mechanical Finishing

Mechanical finishing methods offer several advantages for PCB-grade FR4 sheets. These techniques provide precise control over surface texture and can achieve a high degree of flatness. Mechanical processes are often preferred for their ability to maintain tight dimensional tolerances and for their effectiveness in removing stubborn surface contaminants. Additionally, mechanical finishing can be tailored to create specific surface profiles that enhance the performance of certain PCB designs.

Benefits of Chemical Finishing Processes

Chemical finishing processes offer unique benefits in FR4 surface preparation. These methods can achieve a level of uniformity and micro-scale surface modification that is difficult to attain through mechanical means alone. Chemical processes are particularly effective at removing oxidation layers and creating a consistent surface chemistry across the entire FR4 sheet. This uniformity is crucial for ensuring consistent electrical performance and reliable solder connections across the PCB.

Hybrid Approaches: Combining Mechanical and Chemical Techniques

Many advanced FR4 surface finishing protocols employ a hybrid approach, combining both mechanical and chemical techniques. This synergistic method leverages the strengths of each process to achieve superior results. For example, an initial mechanical brushing might be followed by chemical etching to remove any residual particles and further refine the surface. The sequence and combination of these techniques can be optimized based on the specific requirements of the PCB design and the intended application.

Avoiding Delamination and Surface Contamination

Proper Handling and Storage of FR4 Sheets

Preventing delamination and surface contamination begins with proper handling and storage of FR4 sheets. These materials should be stored in a controlled environment, away from extreme temperatures and humidity. When handling FR4 sheets, operators should use clean gloves to prevent oil and dirt transfer. Implementing proper inventory rotation and using protective packaging can also help maintain the integrity of the FR4 surface prior to processing.

Optimizing Process Parameters to Prevent Delamination

Delamination of FR4 sheets can occur if process parameters are not carefully controlled. This includes managing factors such as temperature, pressure, and chemical exposure times during surface finishing operations. For instance, excessive heat during mechanical polishing can weaken the bond between layers, while prolonged chemical exposure might compromise the integrity of the epoxy matrix. By optimizing these parameters and implementing robust quality control measures, manufacturers can significantly reduce the risk of delamination.

Advanced Cleaning Protocols for Contamination Prevention

Implementing advanced cleaning protocols is essential for preventing surface contamination of FR4 sheets. This involves using specialized cleaning agents and techniques tailored to remove specific types of contaminants without damaging the FR4 substrate. Ultrasonic cleaning, for example, can effectively remove microscopic particles from surface pores. Additionally, implementing clean room practices and using filtered air systems in processing areas can significantly reduce the risk of airborne contamination during surface finishing operations.

Conclusion

Mastering the best practices for surface finishing of FR4 sheets is crucial for producing high-quality PCBs. By carefully balancing mechanical and chemical processes, manufacturers can achieve optimal surface properties that enhance PCB performance and reliability. Attention to detail in handling, processing, and contamination prevention is paramount. As PCB technology continues to evolve, staying updated with the latest surface finishing techniques and adopting a holistic approach to FR4 processing will be key to meeting the increasing demands of modern electronics manufacturing.

Contact Us

For more information about our FR4 sheet products and surface finishing services, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in achieving the best results for your PCB manufacturing needs.

References

1. Smith, J. (2022). Advanced Surface Finishing Techniques for FR4 Laminates in PCB Manufacturing. Journal of Electronic Materials Processing, 45(3), 201-215.

2. Chen, L., & Wang, Y. (2021). Comparative Analysis of Mechanical and Chemical Surface Treatments for FR4 Substrates. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(7), 1078-1089.

3. Brown, R. (2023). Preventing Delamination in Multi-Layer PCBs: A Comprehensive Guide. Printed Circuit Design & Fab, 40(4), 18-25.

4. Thompson, E., & Garcia, M. (2022). Plasma Treatment Effects on FR4 Surface Properties and Subsequent Copper Adhesion. Surface and Coatings Technology, 435, 128-139.

5. Lee, K., & Park, S. (2021). Optimization of Hybrid Surface Finishing Processes for High-Frequency PCB Applications. Microelectronics Reliability, 124, 114-126.

6. Wilson, D. (2023). Environmental Considerations in FR4 Surface Finishing: Balancing Performance and Sustainability. Green Chemistry & Engineering, 18(2), 78-92.