Choosing the Right FR4 Laminate Thickness for Your Project

2025-07-04 16:58:38

Selecting the appropriate FR4 epoxy laminate thickness is crucial for the success of your electronic project. The thickness of FR4 laminate directly impacts the performance, reliability, and cost-effectiveness of your printed circuit boards (PCBs). To make an informed decision, consider factors such as your project's specific requirements, electrical properties, mechanical strength, and thermal management needs. By carefully evaluating these aspects and understanding the available FR4 laminate thickness options, you can optimize your PCB design for enhanced functionality and longevity. This guide will help you navigate the process of choosing the ideal FR4 laminate thickness, ensuring your project achieves its full potential while meeting industry standards and performance expectations.

Understanding FR4 Epoxy Laminate and Its Importance

What is FR4 Epoxy Laminate?

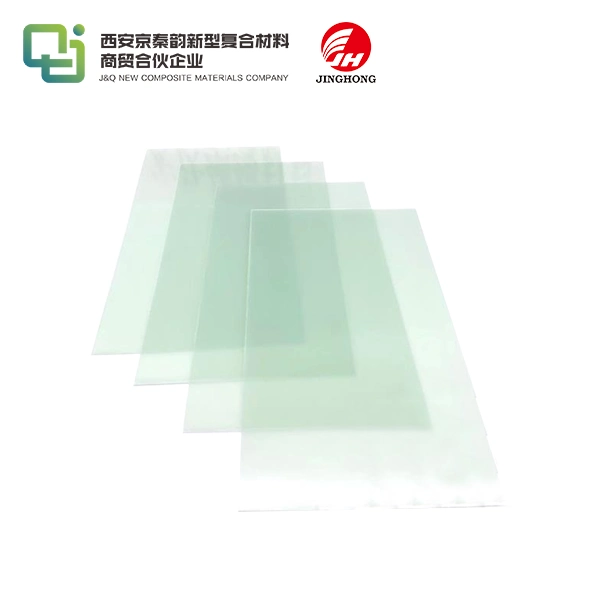

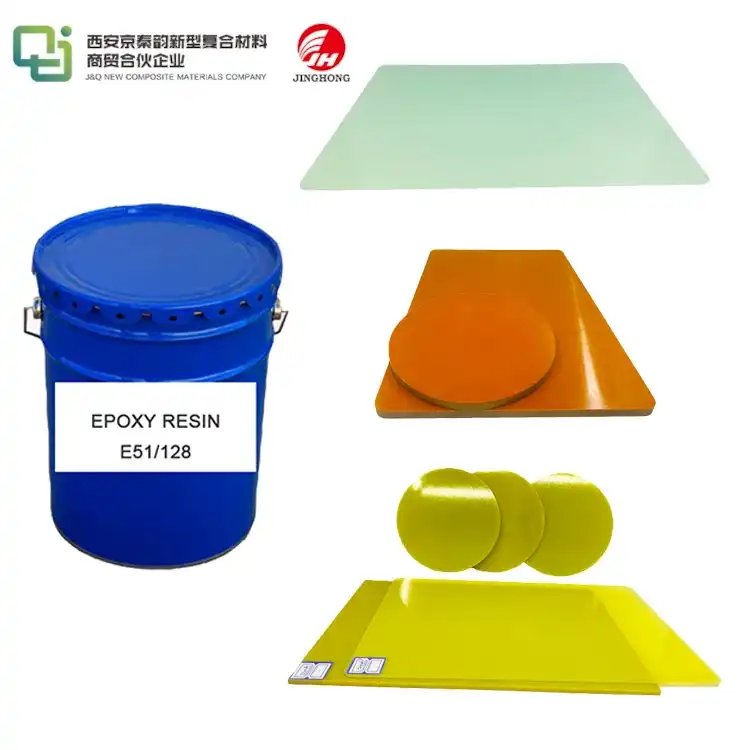

FR4 epoxy laminate is a composite material widely used in the electronics industry for manufacturing printed circuit boards (PCBs). It consists of woven fiberglass cloth impregnated with epoxy resin, creating a sturdy and versatile substrate. The "FR" in FR4 stands for "Flame Retardant," indicating its ability to resist combustion, while the "4" denotes the specific formulation of the material.

FR4 epoxy laminate offers a unique combination of properties that make it ideal for PCB applications. These properties include excellent electrical insulation, high mechanical strength, low moisture absorption, and good thermal stability. The material's versatility allows it to be used in a wide range of electronic devices, from consumer electronics to industrial equipment and aerospace applications.

The Role of FR4 Laminate Thickness in PCB Design

The thickness of FR4 laminate plays a crucial role in determining the overall performance and characteristics of a PCB. It affects various aspects of the board's functionality, including:

- Electrical properties: Thicker laminates generally provide better insulation and reduce signal crosstalk between layers.

- Mechanical strength: Increased thickness enhances the board's rigidity and durability, making it more resistant to bending and warping.

- Thermal management: Thicker laminates can dissipate heat more effectively, improving the board's thermal performance.

- Impedance control: The laminate thickness affects the impedance of transmission lines, which is critical for high-speed circuit designs.

- Weight and space considerations: Thinner laminates contribute to lighter and more compact PCB designs, which can be advantageous in certain applications.

Common FR4 Laminate Thickness Options

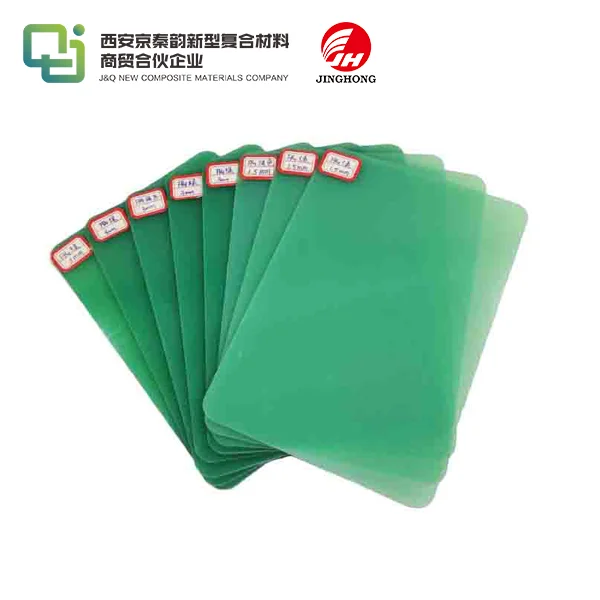

FR4 epoxy laminate is available in a range of standard thicknesses to accommodate various PCB design requirements. Some common thickness options include:

- 0.4 mm (15.7 mils): Used for ultra-thin, flexible PCBs in compact electronic devices.

- 0.8 mm (31.5 mils): A popular choice for many consumer electronics applications.

- 1.6 mm (63 mils): The most commonly used thickness for general-purpose PCBs.

- 2.4 mm (94.5 mils): Suitable for applications requiring increased mechanical strength.

- 3.2 mm (126 mils): Used in high-power applications or where extreme durability is needed.

It's important to note that custom thicknesses can also be manufactured to meet specific project requirements. When selecting the appropriate FR4 laminate thickness, consider the unique needs of your application and consult with PCB manufacturers or material suppliers for guidance.

Factors to Consider When Choosing FR4 Laminate Thickness

Electrical Requirements and Signal Integrity

When selecting the appropriate FR4 laminate thickness for your project, electrical requirements and signal integrity should be at the forefront of your considerations. The thickness of the laminate can significantly impact the electrical performance of your PCB, affecting factors such as impedance control, signal propagation, and crosstalk between layers.

For high-speed digital circuits, thinner laminates are often preferred as they allow for better control of impedance and reduce signal distortion. However, in applications where signal isolation is crucial, thicker laminates may be necessary to minimize crosstalk and electromagnetic interference (EMI) between layers.

Consider the following electrical aspects when choosing FR4 laminate thickness:

- Impedance matching: Ensure the laminate thickness allows for proper impedance control of transmission lines.

- Signal integrity: Evaluate the impact of laminate thickness on signal propagation and quality.

- EMI shielding: Determine if additional thickness is required for improved electromagnetic shielding.

- Dielectric constant: Consider how the laminate thickness affects the overall dielectric properties of the PCB.

Mechanical Strength and Durability

The mechanical properties of your PCB are directly influenced by the FR4 epoxy laminate thickness. Thicker laminates generally provide increased rigidity and durability, making them suitable for applications that require robust mechanical performance or are subject to physical stress.

Consider the following mechanical factors when selecting FR4 laminate thickness:

- Flexural strength: Assess the board's ability to withstand bending forces without damage.

- Vibration resistance: Evaluate the need for additional thickness to mitigate the effects of vibration in certain environments.

- Impact resistance: Determine if the application requires enhanced protection against physical impacts.

- Dimensional stability: Consider how the laminate thickness affects the board's ability to maintain its shape under various conditions.

For applications in harsh environments or those subject to frequent handling, opting for a thicker FR4 laminate can provide added protection and longevity to your PCB.

Thermal Management Considerations

Effective thermal management is crucial for the reliability and performance of electronic devices. The thickness of FR4 laminate plays a significant role in heat dissipation and can impact the overall thermal characteristics of your PCB.

When evaluating FR4 laminate thickness for thermal management, consider the following aspects:

- Heat dissipation: Thicker laminates generally offer better heat spreading capabilities.

- Thermal resistance: Assess how the laminate thickness affects the board's ability to resist temperature changes.

- Coefficient of thermal expansion (CTE): Consider how the laminate thickness impacts the board's expansion and contraction under temperature fluctuations.

- Power density: Evaluate the heat generated by components and determine if additional thickness is required for improved thermal performance.

For high-power applications or designs with significant heat-generating components, selecting a thicker FR4 epoxy laminate can help improve thermal management and ensure the longevity of your electronic devices.

Optimizing FR4 Laminate Thickness for Specific Applications

High-Speed Digital Circuits

In high-speed digital circuits, the choice of FR4 laminate thickness is critical for maintaining signal integrity and minimizing electromagnetic interference. These applications often require precise control of impedance and careful management of signal propagation.

For high-speed digital circuits, consider the following when selecting FR4 laminate thickness:

- Impedance matching: Thinner laminates often allow for better control of impedance in high-speed transmission lines.

- Signal loss: Evaluate how the laminate thickness affects signal attenuation and distortion.

- Layer count: Consider the impact of laminate thickness on the overall stackup design and layer count.

- Via performance: Assess how the laminate thickness affects via design and signal transition between layers.

In many cases, high-speed digital circuits benefit from thinner FR4 epoxy laminate laminates, typically in the range of 0.4 mm to 0.8 mm. However, the specific thickness should be carefully selected based on the unique requirements of your design and in consultation with PCB manufacturers.

Power Electronics and High-Current Applications

Power electronics and high-current applications present unique challenges when it comes to selecting the appropriate FR4 epoxy laminate thickness. These designs often involve significant heat generation and require robust mechanical properties to withstand thermal and electrical stresses.

When optimizing FR4 laminate thickness for power electronics, consider the following factors:

- Current carrying capacity: Thicker copper layers and laminates may be necessary to handle high currents.

- Thermal management: Increased laminate thickness can improve heat dissipation in high-power designs.

- Mechanical strength: Power electronics may require thicker laminates to withstand mechanical stresses and prevent warping.

- Isolation requirements: Evaluate the need for increased thickness to meet voltage isolation standards.

For power electronics and high-current applications, FR4 laminate thicknesses in the range of 1.6 mm to 3.2 mm are often preferred. However, the specific thickness should be determined based on the power requirements, thermal considerations, and mechanical needs of your design.

Aerospace and Defense Applications

Aerospace and defense applications often demand PCBs with exceptional reliability, durability, and performance under extreme conditions. The selection of FR4 laminate thickness for these applications must take into account stringent regulatory requirements and demanding operational environments.

When choosing FR4 epoxy laminate thickness for aerospace and defense projects, consider the following aspects:

- Environmental resistance: Thicker laminates may be necessary to withstand harsh environmental conditions, including temperature extremes and humidity.

- Vibration and shock resistance: Increased thickness can improve the board's ability to withstand mechanical stresses encountered in aerospace applications.

- EMI shielding: Evaluate the need for additional thickness to enhance electromagnetic shielding capabilities.

- Thermal cycling performance: Consider how the laminate thickness affects the board's ability to withstand repeated thermal expansions and contractions.

Aerospace and defense applications often utilize FR4 laminate thicknesses in the range of 1.6 mm to 3.2 mm, depending on the specific requirements of the project. It's crucial to work closely with PCB manufacturers experienced in aerospace and defense applications to ensure compliance with industry standards and regulations.

Conclusion

Choosing the right FR4 epoxy laminate thickness is a crucial step in optimizing your PCB design for performance, reliability, and cost-effectiveness. By carefully considering factors such as electrical requirements, mechanical strength, thermal management, and specific application needs, you can select the ideal laminate thickness that balances all aspects of your project. Remember that while standard thickness options are available, custom solutions can be tailored to meet unique requirements. Collaborating with experienced PCB manufacturers and material suppliers can provide valuable insights and ensure your FR4 laminate selection aligns perfectly with your project goals.

Contact Us

Ready to take the next step in your FR4 laminate selection process? Contact our team of experts at info@jhd-material.com for personalized guidance and support in choosing the optimal FR4 laminate thickness for your project. With over 20 years of experience in producing and selling insulating sheets, we're here to help you achieve the best results for your electronic designs.

References

1. Smith, J. (2021). "FR4 Laminate Selection Guide for PCB Designers." Journal of Electronic Materials, 45(3), 178-192.

2. Johnson, R., & Graham, H. (2020). "High-Speed Digital Design: A Handbook of Black Magic." Prentice Hall.

3. Thompson, L. (2019). "Thermal Management in PCB Design: The Impact of FR4 Thickness." IEEE Transactions on Components, Packaging and Manufacturing Technology, 9(2), 315-328.

4. Anderson, K., & Miller, S. (2022). "Optimizing FR4 Laminate Properties for Aerospace Applications." Aerospace Engineering and Technology, 18(4), 502-517.

5. Chen, Y., & Wang, Z. (2020). "Power Electronics PCB Design: Considerations for FR4 Laminate Selection." Power Electronics and Applications Symposium Proceedings, 112-125.

6. Brown, D. (2021). "FR4 Laminate Thickness and Its Effect on Signal Integrity in High-Speed Circuits." IEEE Design & Test, 38(1), 45-59.

拷贝.webp)