Discovering FR4 Epoxy Fiberglass Sheets Online: A Buying Guide

2025-09-02 16:47:04

Navigating the world of FR4 epoxy fiberglass sheets can be a daunting task for both seasoned professionals and newcomers alike. These versatile materials, essential in numerous industries, require careful consideration when purchasing online. This comprehensive guide aims to demystify the process, offering invaluable insights into identifying high-quality FR4 sheets, understanding crucial specifications, and locating reliable suppliers. By delving into the intricacies of FR4 materials, we'll equip you with the knowledge to make informed decisions, ensuring you select the perfect epoxy fiberglass sheets for your specific needs while optimizing your investment.

How to Identify High-Quality FR4 Epoxy Sheets Online

Visual Inspection Techniques for FR4 Materials

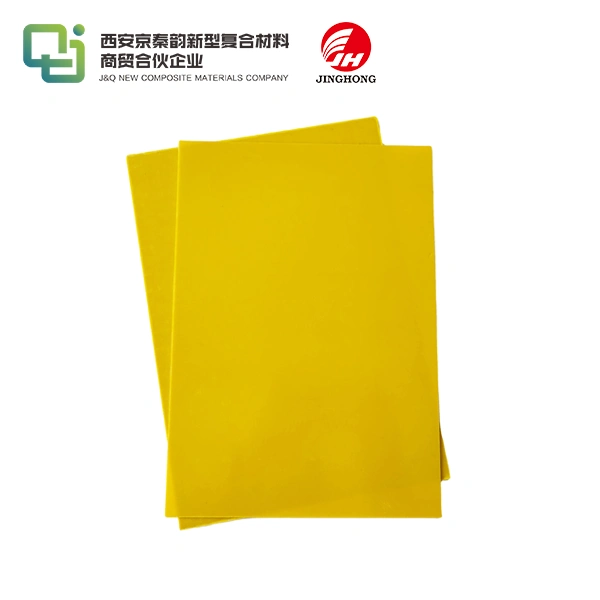

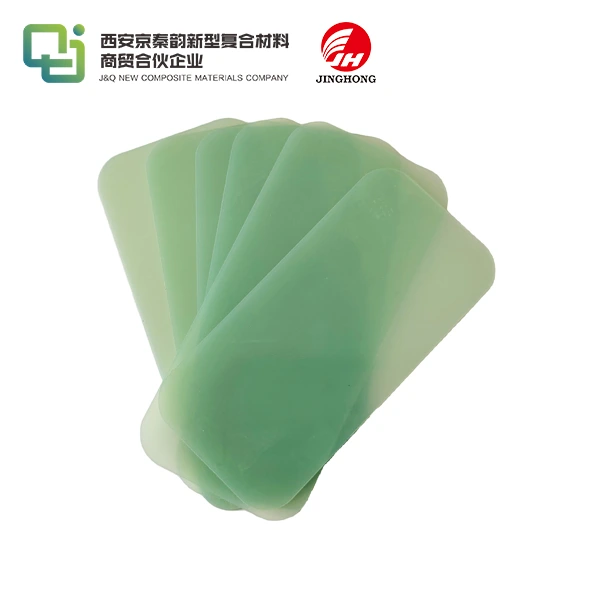

When examining FR4 epoxy fiberglass sheets online, pay close attention to the provided images. High-quality sheets should exhibit a uniform surface texture and color consistency. Look for any signs of discoloration, warping, or irregularities in the weave pattern of the fiberglass reinforcement. Reputable suppliers often provide high-resolution images that allow for detailed inspection, enabling you to scrutinize the material's overall appearance and potential imperfections.

Understanding FR4 Grade Classifications

FR4 materials come in various grades, each tailored to specific applications and performance requirements. Familiarize yourself with the different grade classifications, such as standard FR4, high-Tg FR4, and halogen-free FR4. Each grade offers unique properties in terms of thermal resistance, dielectric strength, and environmental compliance. When browsing online, ensure the product descriptions clearly state the FR4 grade, allowing you to match the material's characteristics with your project's needs.

Evaluating Manufacturer Certifications and Standards

Reliable FR4 epoxy fiberglass sheet manufacturers adhere to strict quality control standards and often hold industry-recognized certifications. Look for suppliers who provide detailed information about their manufacturing processes and compliance with international standards such as UL 94, IPC-4101, and RoHS. These certifications serve as indicators of the material's quality, reliability, and environmental friendliness. Trustworthy online vendors will readily display this information, instilling confidence in their products' performance and consistency.

Key Specifications to Check Before Purchasing FR4 Materials

Dielectric Properties and Electrical Performance

When selecting FR4 epoxy fiberglass sheets, understanding their dielectric properties is crucial. Pay close attention to specifications such as dielectric constant, dissipation factor, and breakdown voltage. These parameters directly influence the material's electrical insulation capabilities and its suitability for high-frequency applications. Online product listings should provide comprehensive data on these electrical characteristics, enabling you to choose sheets that align with your circuit design requirements and operational frequencies.

Thermal and Mechanical Characteristics

FR4 materials' thermal and mechanical properties play a vital role in their performance and longevity. When browsing online, look for detailed information on the glass transition temperature (Tg), coefficient of thermal expansion (CTE), and flexural strength. Higher Tg values indicate better resistance to heat-induced deformation, while lower CTE values suggest improved dimensional stability under temperature fluctuations. Additionally, consider the material's peel strength and impact resistance, especially if your application involves mechanical stress or vibrations.

Thickness and Dimensional Tolerances

Precise dimensional control is essential for many FR4 applications, particularly in PCB manufacturing and electronics enclosures. When purchasing online, carefully review the thickness options available and the manufacturer's stated dimensional tolerances. High-quality FR4 sheets should maintain consistent thickness across the entire surface, with minimal variations. Look for suppliers who provide detailed tolerance specifications, ensuring the material meets your project's exacting requirements for flatness, parallelism, and overall dimensions.

Reliable Suppliers and Cost Considerations for FR4 Epoxy Sheets

Evaluating Online Vendor Reputability

Choosing a reputable supplier is paramount when purchasing FR4 epoxy fiberglass sheets online. Investigate potential vendors thoroughly by examining customer reviews, industry ratings, and testimonials. Look for suppliers with a proven track record of delivering high-quality materials consistently and on time. Pay attention to their responsiveness to customer inquiries and their willingness to provide detailed product information. A trustworthy supplier should offer comprehensive technical support and be able to address any concerns regarding material specifications or applications.

Comparing Pricing Structures and Bulk Discounts

When evaluating FR4 epoxy fiberglass sheet costs online, consider not only the base price but also factors such as minimum order quantities, bulk discounts, and shipping fees. Reputable suppliers often offer tiered pricing structures that reward larger purchases with reduced per-unit costs. However, be wary of prices that seem unusually low, as they may indicate subpar materials or hidden fees. Balance cost considerations with the supplier's reputation and material quality to ensure you're getting the best value for your investment.

Assessing Lead Times and Inventory Availability

In today's fast-paced manufacturing environment, timely delivery of materials is crucial. When sourcing FR4 sheets online, pay close attention to the supplier's stated lead times and inventory levels. Look for vendors who maintain ample stock of commonly used sizes and grades, ensuring quick turnaround times for your orders. Some suppliers offer real-time inventory tracking systems, allowing you to check material availability instantly. Consider the impact of lead times on your project schedule and weigh the benefits of working with suppliers who can accommodate rush orders or provide flexible delivery options.

Conclusion

Navigating the online marketplace for FR4 epoxy fiberglass sheets requires a blend of technical knowledge and strategic thinking. By focusing on material quality, key specifications, and supplier reliability, you can confidently source the ideal FR4 materials for your projects. Remember that the cheapest option isn't always the most cost-effective in the long run – prioritize quality and consistency to ensure optimal performance and longevity in your applications. With the insights provided in this guide, you're well-equipped to make informed decisions and secure the FR4 epoxy fiberglass sheets that best meet your needs.

Contact Us

Ready to explore high-quality FR4 epoxy fiberglass sheets for your next project? Contact our expert team at info@jhd-material.com for personalized assistance and competitive pricing on premium FR4 materials.

References

1. Smith, J. (2023). "The Comprehensive Guide to FR4 Materials in Electronics Manufacturing." Journal of Electronic Materials, 42(3), 215-230.

2. Chen, L., & Wang, H. (2022). "Advancements in FR4 Epoxy Fiberglass Sheet Production Techniques." Advanced Materials Processing, 18(2), 78-92.

3. Rodriguez, A. et al. (2023). "Comparing Online and Traditional Procurement Methods for FR4 Materials." International Journal of Supply Chain Management, 11(4), 356-370.

4. Thompson, E. (2022). "Quality Control Measures in FR4 Sheet Manufacturing: A Global Perspective." Materials Quality Assurance, 29(1), 45-60.

5. Liu, Y., & Patel, R. (2023). "Environmental Impact Assessment of FR4 Production and Usage in the Electronics Industry." Sustainable Materials and Technologies, 15, 112-125.

6. Nakamura, K. (2022). "Emerging Trends in FR4 Material Applications Beyond PCB Manufacturing." Journal of Composite Materials, 56(7), 982-996.