Fiberglass Board Emerges as a Popular Choice for Smart Terminals such as Mobile Phones and Tablets

2021-07-01

As a kind of man-made fiber board, fiberglass sheet is widely used in PCB board, tablet computer shell, keyboard two-in-one kit because of its good heat resistance, chemical stability and tensile strength. And on mobile phones, plain skin laminated glass fiber board or glass fiber board sprayed back cover has also become a popular choice.

The white shell of Huawei MatePad Pro is made of fiberglass sheet, as well as its folding screen Mate X and XS shells. This material has the characteristics of high toughness and light weight, which is not only resistant to falling but also lighter.

Apple's two-in-one light office, mobile office iPad kit, the keyboard structure is made of glass fiber board, which is light and easy to carry on business trips. There are rumors that the next-generation iPad case may also be made of fiberglass board.

Fiberglass board, also known as fiberglass insulation board, fiberglass board (FR-4), FR4 sheet, glass fiber composite board, is composed of glass fiber materials and high heat-resistant composite materials, and does not contain asbestos harmful to the human body. The elasticity and modulus of glass fiber board are generally 30~40Gpa. It has higher mechanical and dielectric properties, better heat resistance and moisture resistance, and good process ability.

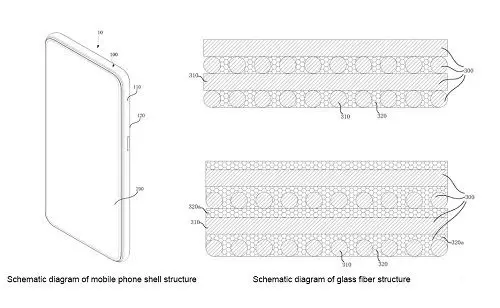

We all know that sheet material is used in product shells, especially consumer electronic products such as mobile phones and iPads, which have strict requirements on flatness. The production process of the board is laminated and stacked, and warping is inevitable. Improving the surface smoothness of the plate can reduce the surface treatment and polishing time, improve the yield, and reduce the processing cost. In order to solve the problem of uneven surface of fiberglass board, OPPO published a patent CN 110712403 A on fiberglass board and its preparation method and electronic equipment in 2020.

|

|

This patent provides a method for preparing a fiberglass board, a fiberglass board prepared by the method and an electronic device for preparing the fiberglass board. By filling the gap between two adjacent glass fiber filaments with an adhesive, the thickness of the single-layer glass fiber cloth is uniform, and then the multilayer glass fiber cloth is laminated and laminated, and the overall thickness of the obtained glass fiber board is also uniform.

With the increasing application of fiberglass board market, fiberglass board processing companies, press, CNC and other equipment companies, and fiberglass cloth material companies are also deepening their layout. In 2020, Zhongke Weihe Technology (Zhaoqing) Co., Ltd. plans to invest a total of 10 million yuan in a composite new material project with an annual output of 5 million square meters. According to reports, the scale of the project mainly includes three 15-layer hot presses, one cold press, and three impregnation machines.

Fiberglass board has emerged and has been favored and praised by many terminal equipment manufacturers. The glass fiber board is light, thin, plastic, can be laminated with PET, plain leather, flame retardant, and good weather resistance. It can not only enhance the novel appearance of current consumer electronic products such as mobile phones and tablets, but also bring excellent touch feel.