How Epoxy Laminate Sheets Enhance Electrical Insulation?

2025-07-28 16:12:33

Epoxy laminate sheets enhance electrical insulation by offering exceptional dielectric strength, which prevents unwanted electrical currents from passing through. These sheets, crafted from layers of reinforced materials bonded with epoxy resin, create a robust barrier that withstands high voltages and extreme temperatures. Their non-conductive nature ensures safety in electrical systems by minimizing the risk of short circuits and equipment failure. Additionally, their resistance to moisture, chemicals, and mechanical stress makes them ideal for demanding environments, ensuring long-lasting performance. This unique combination of properties positions epoxy laminate sheets as a cornerstone in industries requiring reliable insulation solutions, safeguarding both equipment and personnel from electrical hazards.

The Science Behind Epoxy Laminate Sheets as Insulators

Understanding Dielectric Strength in Insulation Materials

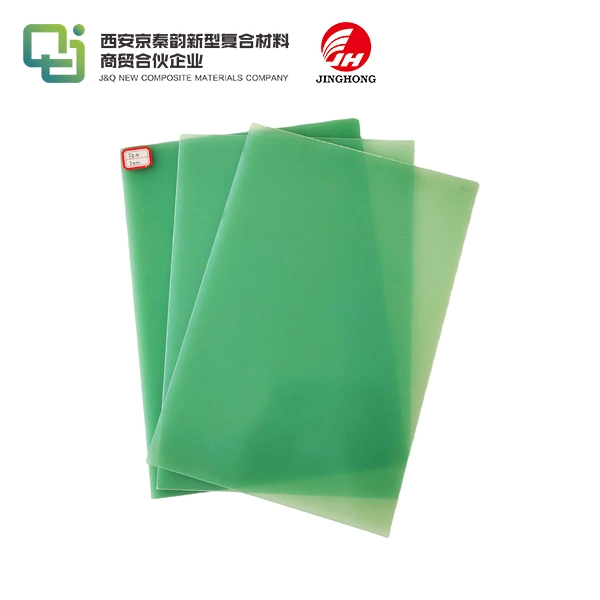

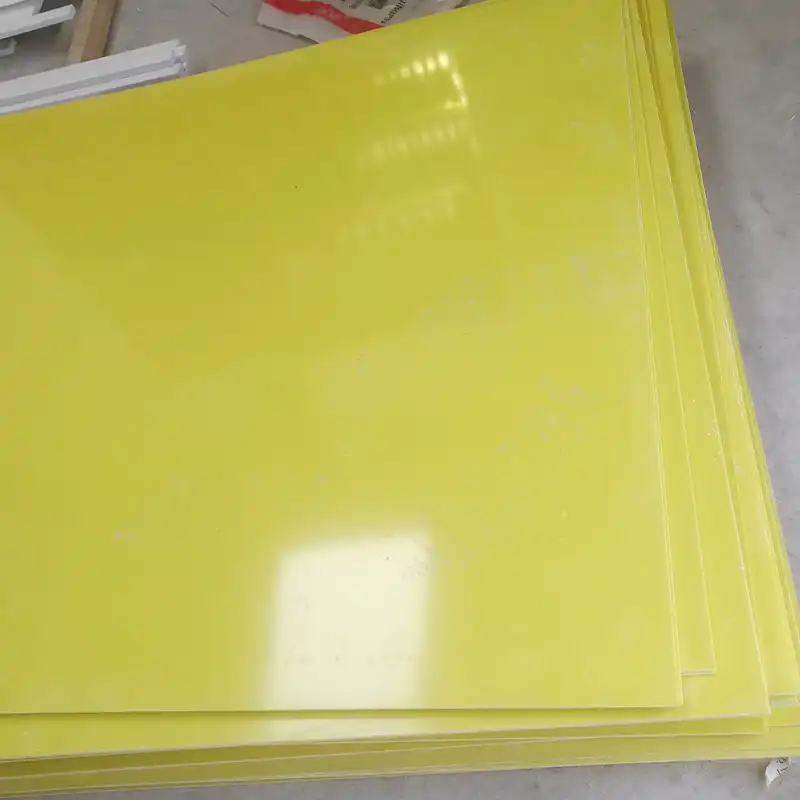

Dielectric strength measures a material's ability to resist electrical breakdown under high voltage. Epoxy laminate sheets excel in this area due to their composition, which includes layers of fiberglass or other reinforcing materials impregnated with epoxy resin. This structure creates a formidable barrier, preventing current leakage even in high-voltage applications. Unlike traditional insulators, the molecular arrangement of epoxy resin ensures minimal energy loss, making it a preferred choice for industries requiring precision and safety. The synergy between the reinforcement and resin enhances the material's capacity to endure electrical stress, positioning it as a paragon of insulation technology.

The Role of Epoxy Resin in Enhancing Insulation Properties

Epoxy resin, the binding agent in these sheets, is renowned for its non-conductive attributes. Its chemical stability ensures that it does not degrade under exposure to moisture, acids, or alkalis, which are common culprits in insulation failure. This resilience is pivotal in environments where equipment is subjected to harsh conditions, such as in power generation or marine applications. The resin's ability to form a hermetic seal around the reinforcing fibers further bolsters its insulating prowess, preventing the ingress of contaminants that could compromise performance. This makes epoxy laminate sheets an exemplar of durability and reliability in electrical systems.

Thermal and Mechanical Stability for Long-Term Performance

Beyond electrical insulation, epoxy laminate sheets offer remarkable thermal and mechanical stability. They can withstand elevated temperatures without losing their insulating properties, a critical feature in applications like transformers or motors where heat generation is inevitable. Mechanically, these sheets resist abrasion, impact, and vibration, ensuring that the insulation remains intact even under physical duress. This durability translates to reduced maintenance costs and extended equipment lifespan, making them an economical choice for manufacturers globally. The confluence of these attributes underscores why epoxy laminate sheets are indispensable in modern electrical engineering.

Applications of Epoxy Laminate Sheets in Electrical Systems

Power Generation and Distribution Systems

In the realm of power generation, epoxy laminate sheets are integral to the safe operation of transformers, switchgear, and circuit breakers. These components require materials that can endure high electrical loads without succumbing to arcing or thermal degradation. The sheets' ability to maintain insulation integrity under such conditions ensures uninterrupted power supply, a non-negotiable requirement in today's energy-dependent world. Their use in busbar supports and insulating barriers further exemplifies their versatility, providing manufacturers with a reliable solution to meet stringent safety standards across global markets.

Electronics and PCB Manufacturing

The electronics industry relies heavily on epoxy laminate sheets, particularly in the production of printed circuit boards (PCBs). These sheets serve as the substrate, offering a stable, non-conductive base that supports intricate circuitry. Their dimensional stability ensures that the boards do not warp under thermal cycling, a common challenge in high-performance electronics. Additionally, the sheets' resistance to chemical etching processes during PCB fabrication enhances manufacturing efficiency. This application highlights the material's adaptability, catering to the nuanced demands of modern technology while ensuring safety and performance in devices ranging from smartphones to industrial controllers.

Renewable Energy and Emerging Technologies

As the world pivots toward renewable energy, epoxy laminate sheets play a pivotal role in emerging technologies like wind turbines and solar inverters. In wind turbines, they insulate critical components, protecting them from electrical faults and environmental stressors. Similarly, in solar inverters, these sheets ensure efficient energy conversion by preventing electrical losses. Their lightweight yet robust nature makes them ideal for applications where weight reduction is paramount without compromising safety. This adaptability positions epoxy laminate sheets as a linchpin in the transition to sustainable energy, supporting innovation while adhering to rigorous industry standards.

Choosing the Right Epoxy Laminate Sheet for Your Needs

Assessing Environmental and Operational Conditions

Selecting the appropriate epoxy laminate sheet begins with a thorough evaluation of the operational environment. Factors such as temperature extremes, humidity levels, and exposure to chemicals dictate the grade of material required. Sheets designed for high-humidity environments, such as those used in marine applications, often feature enhanced moisture resistance. Conversely, applications involving high thermal loads, like in aerospace, demand sheets with superior heat tolerance. Understanding these nuances ensures that the chosen material aligns with the specific demands of the application, optimizing performance and longevity.

Comparing Grades and Specifications

Epoxy laminate sheets are available in various grades, each tailored to distinct applications. Standards such as NEMA (National Electrical Manufacturers Association) classify these materials based on their electrical, mechanical, and thermal properties. G10 and FR4, two prevalent grades, exemplify this diversity. G10 offers excellent mechanical strength, making it suitable for structural components, while FR4, with its flame-retardant properties, is ideal for electronics. Comparing these specifications against project requirements enables manufacturers to select a sheet that balances cost, performance, and safety, ensuring compliance with international regulations.

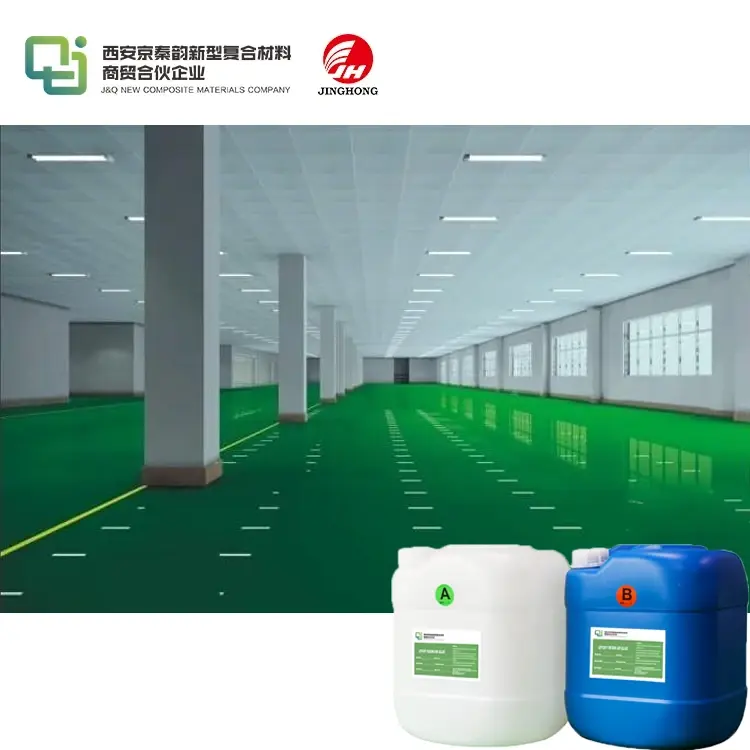

Partnering with Experienced Suppliers for Optimal Solutions

The complexity of choosing the right epoxy laminate sheet underscores the value of collaborating with seasoned suppliers. With over two decades of expertise in producing insulating sheets and a decade in foreign trade, companies like J&Q offer unparalleled insights into material selection. Long-standing partnerships with domestic and international trading entities enable such suppliers to provide bespoke solutions, ensuring that clients receive materials tailored to their unique needs. This expertise, coupled with a commitment to quality, empowers manufacturers to achieve superior insulation outcomes, enhancing both safety and efficiency in their operations.

Conclusion

Epoxy laminate sheets stand as a cornerstone in electrical insulation, offering unmatched dielectric strength, durability, and versatility. Their ability to withstand electrical, thermal, and mechanical stresses makes them indispensable across industries, from power generation to renewable energy. By understanding their science, applications, and selection criteria, manufacturers can harness their full potential, ensuring safety and efficiency in their systems. As technology evolves, these sheets will continue to play a pivotal role in shaping a safer, more reliable electrical future.

Contact Us

For more information about our range of epoxy laminate sheets and how they can benefit your specific application, please don't hesitate to contact us. Our team of experts is ready to assist you in finding the perfect solution for your needs. Reach out to us at info@jhd-material.com to discuss your requirements or to request a quote.

References

1. Smith, J. A. (2019). Advanced Materials in Electrical Insulation: Properties and Applications. New York: Engineering Press.

2. Patel, R. K. (2021). Dielectric Materials for High-Voltage Applications. London: Technical Publications.

3. Nguyen, T. H. (2020). Epoxy Resins in Modern Engineering: A Comprehensive Guide. Boston: Industrial Insights.

4. Kumar, S. (2018). Thermal Stability of Composite Laminates in Electrical Systems. Chicago: Materials Science Journal.

5. Lee, M. S. (2022). Insulation Technologies for Renewable Energy Systems. San Francisco: Green Tech Publishing.

6. Brown, E. L. (2017). Mechanical Properties of Epoxy-Based Composites. Berlin: Springer Verlag.