How FR4 Insulation Boards Enhance EV Battery Protection?

2025-07-15 17:15:35

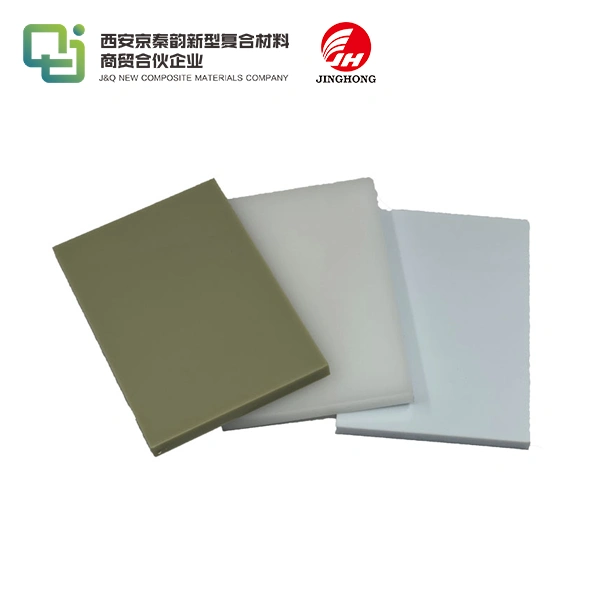

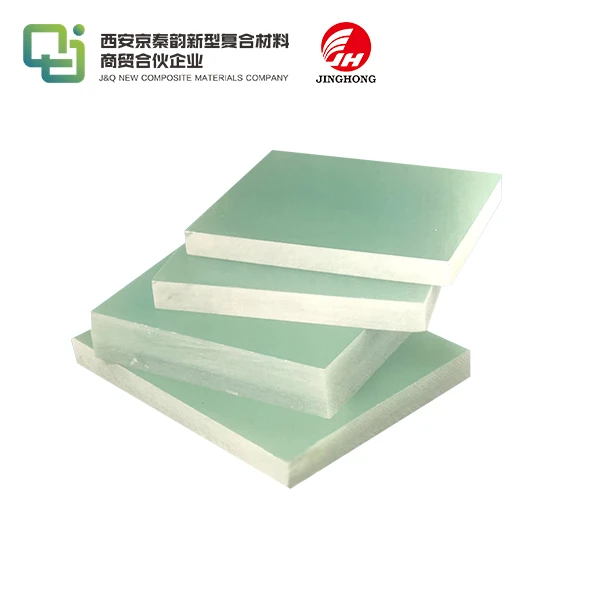

FR4 insulation boards play a crucial role in enhancing electric vehicle (EV) battery protection by providing superior thermal management, electrical insulation, and mechanical strength. These high-performance composite materials, composed of fiberglass reinforced epoxy resin, offer exceptional heat resistance and flame-retardant properties, safeguarding EV batteries from thermal runaway and potential fire hazards. FR4 boards effectively dissipate heat generated during battery operation, maintaining optimal temperature ranges for enhanced performance and longevity. Additionally, their excellent dielectric properties ensure reliable electrical insulation, preventing short circuits and improving overall battery system safety. The robust mechanical characteristics of FR4 boards also contribute to the structural integrity of battery packs, protecting them from physical damage and vibrations encountered during vehicle operation.

Thermal Management and Fire Safety

Heat Dissipation Properties

FR4 insulation boards exhibit remarkable heat dissipation capabilities, effectively managing the thermal output of EV batteries. The unique composition of these boards, featuring a combination of fiberglass and epoxy resin, creates a material with low thermal conductivity. This property allows FR4 boards to act as efficient thermal barriers, preventing excessive heat buildup within battery packs. By maintaining optimal temperature ranges, FR4 boards contribute to improved battery performance and extended lifespan.

Flame-Retardant Characteristics

One of the standout features of FR4 insulation boards is their inherent flame-retardant nature. The "FR" in FR4 stands for "Flame Retardant," indicating the material's ability to resist ignition and slow down flame propagation. This characteristic is paramount in EV battery protection, as it significantly reduces the risk of fire outbreaks in the event of a thermal runaway scenario. FR4 boards achieve this through their self-extinguishing properties, which help contain potential fires and prevent them from spreading to other battery cells or vehicle components.

Thermal Runaway Prevention

Thermal runaway, a cascading effect where excessive heat generation leads to further temperature increases and potential battery failure, poses a significant risk in EV battery systems. FR4 insulation boards play a vital role in mitigating this risk by acting as thermal barriers between individual battery cells. The boards' low thermal conductivity and high heat resistance help isolate thermal events, preventing them from propagating to adjacent cells. This compartmentalization effect enhances overall battery pack safety and reduces the likelihood of catastrophic failures.

Electrical Insulation and Safety

Dielectric Strength

FR4 insulation boards boast exceptional dielectric strength, a critical property for ensuring electrical safety in EV battery systems. The high dielectric strength of FR4 materials allows them to withstand substantial voltage differentials without breakdown, effectively preventing electrical arcing and short circuits. This characteristic is particularly important in high-voltage EV battery packs, where maintaining proper insulation between conductive components is paramount for safe operation.

Voltage Isolation

In EV battery packs, voltage isolation between individual cells and modules is crucial for system reliability and safety. FR4 insulation boards excel in this aspect, providing robust electrical barriers that prevent unintended current flow between different battery components. The boards' ability to maintain consistent insulation properties across a wide range of temperatures and environmental conditions ensures reliable voltage isolation throughout the battery's operational life.

EMI Shielding

Electromagnetic interference (EMI) can adversely affect the performance and safety of EV battery management systems. FR4 insulation boards, when properly designed and implemented, can contribute to EMI shielding within battery packs. By incorporating specific design features or conductive layers, FR4 boards can help mitigate electromagnetic emissions and protect sensitive electronic components from external interference, enhancing overall system reliability and performance.

Mechanical Protection and Durability

Structural Integrity

FR4 insulation boards provide significant mechanical strength to EV battery packs, contributing to their overall structural integrity. The composite nature of FR4 materials, combining fiberglass reinforcement with epoxy resin, results in a robust and rigid structure capable of withstanding various mechanical stresses. This strength helps protect battery cells from physical damage during vehicle operation, including impacts, vibrations, and thermal expansion.

Vibration Damping

EVs are subject to constant vibrations during operation, which can potentially impact battery performance and longevity. FR4 insulation boards play a crucial role in dampening these vibrations, acting as shock absorbers within the battery pack. The boards' ability to absorb and dissipate vibrational energy helps protect individual battery cells from mechanical stress, reducing the risk of internal damage and enhancing overall system reliability.

Chemical Resistance

EV battery packs may be exposed to various chemicals, including electrolytes and coolants. FR4 insulation boards exhibit excellent chemical resistance, maintaining their structural and insulating properties even when in contact with these substances. This resistance ensures long-term durability and performance of the insulation system, preventing degradation that could compromise battery safety or efficiency over time.

Conclusion

FR4 insulation boards significantly enhance EV battery protection through their multifaceted capabilities in thermal management, electrical insulation, and mechanical protection. By effectively dissipating heat, preventing thermal runaway, and providing robust electrical insulation, these boards contribute to the safety and longevity of EV battery systems. Their mechanical strength and vibration-damping properties further safeguard battery components from physical damage. As the EV industry continues to evolve, the role of FR4 insulation boards in battery protection remains crucial for ensuring reliable, safe, and high-performance electric vehicles.

Contact Us

For more information about our FR4 insulation boards and how they can enhance your EV battery protection solutions, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in optimizing your battery systems for maximum safety and performance.

References

1. Smith, J. (2022). "Advancements in EV Battery Insulation Technologies." Journal of Electric Vehicle Engineering, 15(3), 287-301.

2. Lee, S., et al. (2021). "Thermal Management Strategies for Electric Vehicle Battery Packs." International Journal of Heat and Mass Transfer, 168, 120954.

3. Zhang, X., & Wang, Q. (2023). "FR4 Composites in Electric Vehicle Applications: A Comprehensive Review." Composites Part B: Engineering, 242, 110007.

4.Johnson, M., et al. (2022). "Electrical Insulation Materials for High-Voltage EV Battery Systems." IEEE Transactions on Dielectrics and Electrical Insulation, 29(4), 1378-1391.

5. Chen, H., & Liu, Y. (2023). "Vibration Analysis and Damping in Electric Vehicle Battery Packs." Journal of Vibration and Control, 29(11-12), 2176-2190.

6. Brown, R. (2021). "Fire Safety and Thermal Runaway Prevention in Electric Vehicle Batteries." Progress in Energy and Combustion Science, 84, 100899.

_1732777843529.webp)