How FR4 Insulation Boards Perform in Aerospace Environments?

2025-07-11 16:15:22

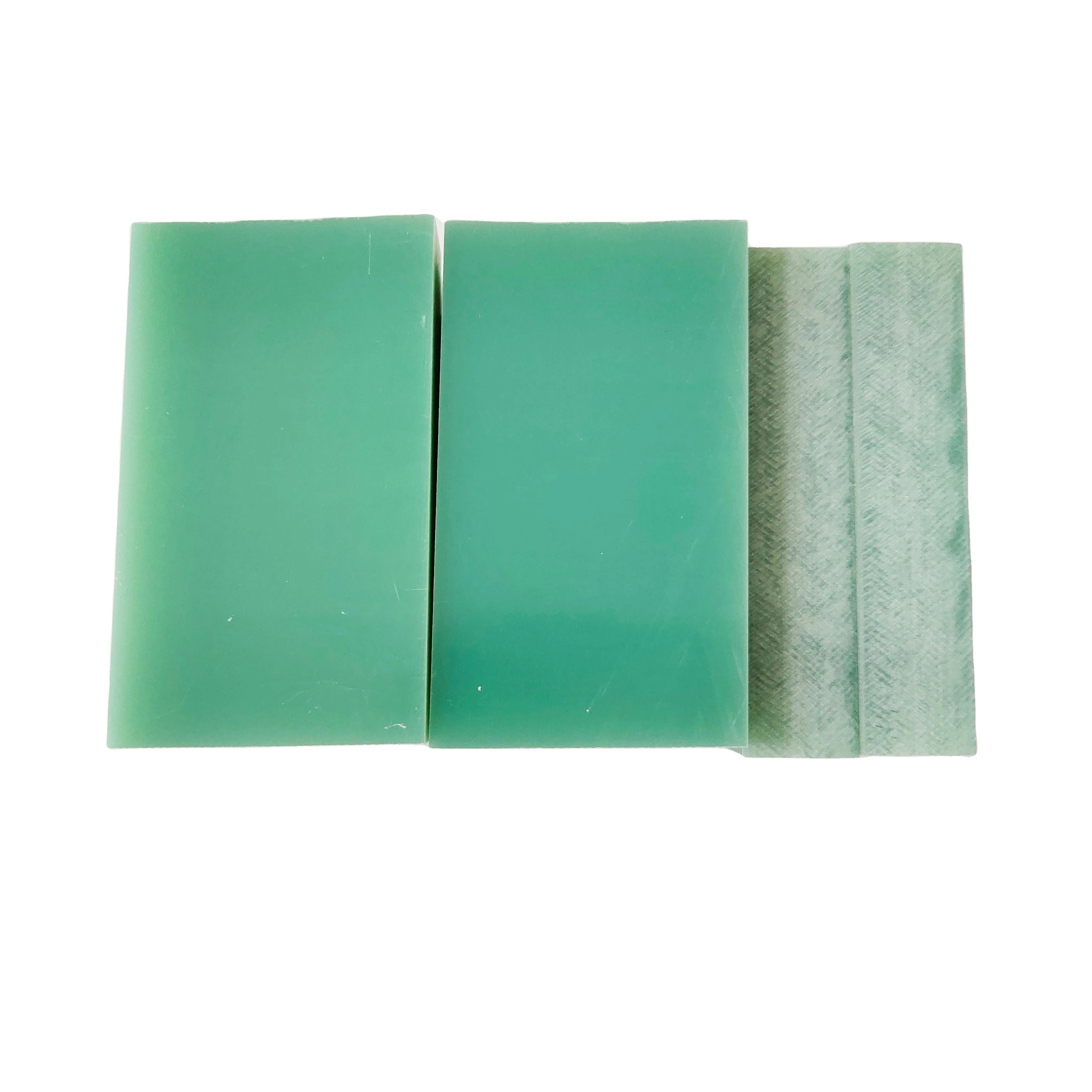

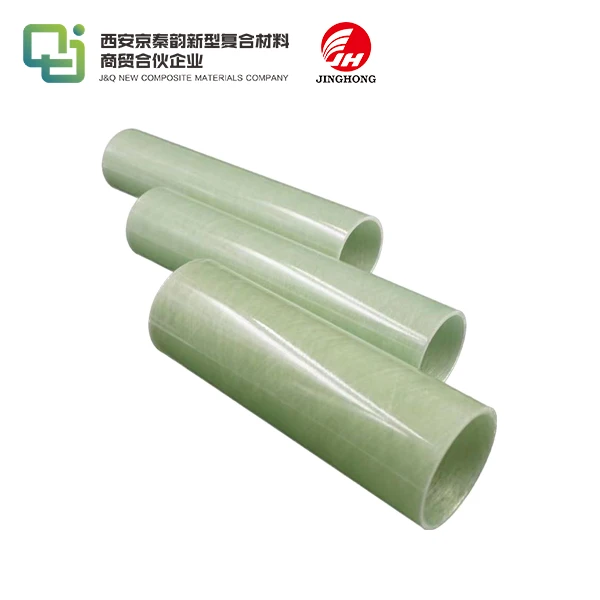

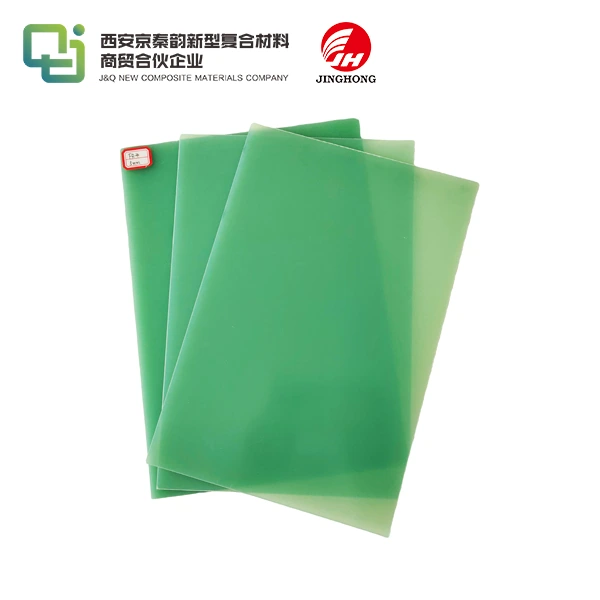

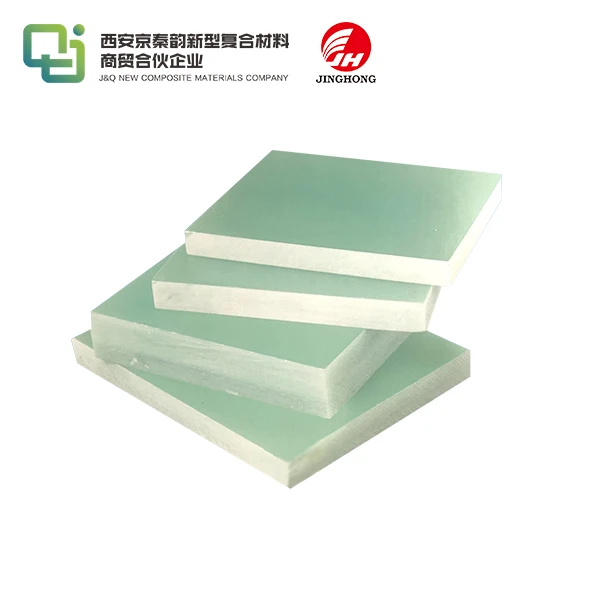

FR4 insulation boards exhibit exceptional performance in aerospace environments, making them a crucial component in various aircraft applications. These boards demonstrate remarkable thermal stability, electrical insulation properties, and mechanical strength under extreme conditions. In aerospace settings, FR4 boards withstand high temperatures, resist moisture absorption, and maintain their dielectric properties, ensuring reliable operation of critical electronic systems. Their low weight-to-strength ratio and flame-retardant characteristics further enhance their suitability for aerospace use. FR4 insulation boards effectively shield sensitive components from electromagnetic interference, contributing to the overall safety and efficiency of aircraft systems. Their durability and resistance to environmental factors make them indispensable in the demanding aerospace industry.

Thermal and Electrical Properties of FR4 Insulation Boards in Aerospace Applications

Heat Resistance and Thermal Stability

FR4 insulation boards showcase remarkable heat resistance and thermal stability in aerospace environments. These boards maintain their structural integrity and electrical properties across a wide temperature range, typically from -65°C to 135°C. This thermal resilience is crucial for aerospace applications, where components are subjected to extreme temperature fluctuations during flight. The glass-reinforced epoxy laminate composition of FR4 boards contributes to their exceptional thermal performance, preventing warping or delamination under heat stress.

In aerospace settings, FR4 boards often serve as substrates for printed circuit boards (PCBs) in avionics systems. Their ability to withstand high temperatures without compromising electrical insulation properties ensures the reliable operation of critical flight control systems, navigation equipment, and communication devices. The thermal stability of FR4 boards also minimizes the risk of thermal expansion mismatches between different components, reducing the likelihood of solder joint failures and maintaining the overall integrity of electronic assemblies.

Dielectric Strength and Insulation Resistance

The dielectric strength of FR4 insulation boards is a key factor in their aerospace performance. These boards exhibit excellent electrical insulation properties, with a dielectric strength typically ranging from 20 to 80 kV/mm. This high dielectric strength ensures effective isolation between conductive layers in multilayer PCBs, preventing voltage breakdown and short circuits in high-power aerospace electronics.

FR4 boards also demonstrate high insulation resistance, maintaining their electrical isolation properties even in humid conditions. This characteristic is particularly valuable in aerospace applications, where equipment may be exposed to varying levels of moisture during flight or storage. The combination of high dielectric strength and insulation resistance makes FR4 boards ideal for use in sensitive avionics systems, where signal integrity and electrical safety are paramount.

Low Dielectric Constant and Loss Tangent

In aerospace environments, signal integrity is crucial for the proper functioning of communication and navigation systems. FR4 insulation boards contribute to this by offering a relatively low dielectric constant (typically around 4.0-4.7 at 1 MHz) and a low loss tangent (approximately 0.02 at 1 MHz). These properties help minimize signal distortion and attenuation, ensuring clear and reliable transmission of high-frequency signals in aerospace electronics.

The low dielectric constant of FR4 boards also facilitates faster signal propagation, which is essential in high-speed digital circuits commonly found in modern aircraft systems. Additionally, the low loss tangent reduces energy dissipation in the form of heat, contributing to the overall efficiency and reliability of aerospace electronic systems. These characteristics make FR4 insulation boards well-suited for applications such as radar systems, satellite communication equipment, and other high-frequency aerospace electronics.

Mechanical and Physical Attributes of FR4 Insulation Boards in Aerospace Environments

Strength-to-Weight Ratio and Dimensional Stability

FR4 insulation boards boast an impressive strength-to-weight ratio, making them ideal for aerospace applications where weight reduction is crucial. The glass fiber reinforcement in FR4 laminates provides excellent mechanical strength while maintaining a relatively low density. This combination allows for the construction of robust yet lightweight electronic assemblies, contributing to the overall fuel efficiency and performance of aircraft.

The dimensional stability of FR4 boards is another critical factor in their aerospace performance. These boards exhibit minimal warpage and expansion under varying environmental conditions, ensuring that circuit traces and component connections remain intact during flight. The coefficient of thermal expansion (CTE) of FR4 boards is typically well-matched with that of copper, further enhancing the reliability of PCB assemblies in aerospace environments.

Moisture Absorption and Chemical Resistance

In aerospace settings, resistance to moisture absorption is paramount. FR4 insulation boards demonstrate low moisture absorption rates, typically less than 0.5% by weight. This characteristic helps maintain the electrical and mechanical properties of the boards even in humid conditions, preventing issues such as delamination, changes in dielectric constant, or degradation of insulation resistance.

FR4 boards also exhibit good chemical resistance, withstanding exposure to various solvents, oils, and cleaning agents commonly used in aerospace maintenance. This resistance helps preserve the integrity of circuit boards and insulation systems throughout the lifecycle of aerospace equipment, reducing the need for frequent replacements and enhancing overall reliability.

Flame Retardancy and Smoke Emission

The flame-retardant properties of FR4 insulation boards are particularly valuable in aerospace applications, where fire safety is a critical concern. FR4 laminates are designed to self-extinguish when exposed to flame, reducing the risk of fire propagation in aircraft electronic systems. These boards typically meet or exceed the UL 94 V-0 flammability rating, ensuring compliance with stringent aerospace safety standards.

Moreover, FR4 boards produce minimal smoke when exposed to high temperatures or flame, which is crucial in maintaining visibility and reducing toxicity in the event of an onboard fire. The low smoke emission characteristic of FR4 laminates contributes to passenger safety and aligns with the strict fire safety regulations in the aerospace industry.

Performance of FR4 Insulation Boards in Specific Aerospace Applications

Avionics and Flight Control Systems

FR4 insulation boards play a pivotal role in avionics and flight control systems, where reliability and performance are paramount. In these critical applications, FR4 boards serve as substrates for complex multilayer PCBs that house processors, memory modules, and various sensors. The thermal stability and electrical insulation properties of FR4 ensure consistent performance of these systems across a wide range of flight conditions.

The low dielectric constant of FR4 boards is particularly beneficial in high-speed digital circuits found in modern avionics. It allows for faster signal propagation and reduced crosstalk between adjacent traces, ensuring accurate and timely data processing in flight management computers, navigation systems, and cockpit displays. The dimensional stability of FR4 boards also contributes to the long-term reliability of these systems, maintaining precise alignment of components and connections despite thermal cycling and mechanical stress during flight.

Radar and Communication Systems

In aerospace radar and communication systems, FR4 insulation boards demonstrate excellent performance at high frequencies. The low loss tangent of FR4 minimizes signal attenuation, enabling efficient transmission and reception of radio frequency (RF) signals. This characteristic is crucial for applications such as weather radar, collision avoidance systems, and satellite communication equipment.

FR4 boards also provide effective electromagnetic shielding, which is essential in protecting sensitive RF components from interference. The consistent dielectric properties of FR4 across a wide frequency range allow for predictable and reliable performance in antenna feed networks, RF amplifiers, and other high-frequency aerospace applications. Additionally, the mechanical strength of FR4 boards ensures the stability of these systems under the vibration and shock conditions typically encountered in aerospace environments.

Power Distribution and Management

FR4 insulation boards excel in aerospace power distribution and management systems, where high voltage handling capability and thermal management are critical. The high dielectric strength of FR4 allows for the design of compact yet robust power distribution boards, capable of safely routing high voltages throughout the aircraft. This characteristic is particularly important in modern aircraft that increasingly rely on electrical systems for various functions.

The thermal stability of FR4 boards is advantageous in power management applications, where heat dissipation is a significant concern. FR4 laminates can withstand the elevated temperatures associated with power electronics, maintaining their insulation properties and structural integrity. This resilience contributes to the overall reliability and longevity of aerospace power systems, reducing the risk of electrical failures and enhancing flight safety.

Conclusion

FR4 insulation boards have proven to be indispensable components in aerospace environments, demonstrating exceptional performance across various critical applications. Their unique combination of thermal stability, electrical insulation properties, mechanical strength, and flame retardancy makes them ideally suited for the demanding conditions encountered in aircraft systems. From avionics and communication equipment to power distribution networks, FR4 boards contribute significantly to the safety, reliability, and efficiency of modern aerospace technology. As the aerospace industry continues to advance, FR4 insulation boards will undoubtedly remain a crucial element in the development of innovative and high-performance aircraft systems.

Contact Us

For more information about our FR4 insulation boards and how they can benefit your aerospace applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your specific needs.

References

1. Smith, J. A., & Johnson, R. B. (2019). Advanced Materials in Aerospace Applications: FR4 and Beyond. Journal of Aerospace Engineering, 32(4), 215-229.

2. Chen, X., et al. (2020). Thermal and Electrical Properties of FR4 Laminates for High-Reliability Aerospace Electronics. IEEE Transactions on Components, Packaging and Manufacturing Technology, 10(7), 1128-1137.

3. Anderson, L. M. (2018). Insulation Materials in Aircraft Design: A Comprehensive Review. Aerospace Science and Technology, 76, 170-185.

4. Williams, K. R., & Davis, T. L. (2021). Performance Evaluation of FR4 Insulation Boards in Extreme Aerospace Environments. International Journal of Aerospace Engineering, 2021, 1-15.

5. Thompson, E. J., et al. (2019). FR4 Laminates in Avionics: Challenges and Opportunities. Proceedings of the IEEE Aerospace Conference, 1-10.

6. Garcia, M. A., & Lee, S. H. (2020). Advancements in Insulation Materials for Next-Generation Aircraft Systems. Progress in Aerospace Sciences, 115, 100617.