How Heat-Resistant is an FR4 Sheet?

2025-05-06 17:21:19

FR4 sheets, widely used in the electronics industry, exhibit remarkable heat resistance properties. These versatile materials can withstand temperatures up to 130°C (266°F) continuously and can briefly endure even higher temperatures without significant degradation. The heat resistance of FR4 sheets stems from their epoxy resin and fiberglass composition, which provides excellent thermal stability. This characteristic makes FR4 sheets ideal for applications in high-temperature environments, such as printed circuit boards (PCBs) in automotive, aerospace, and industrial equipment. However, it's crucial to note that while FR4 sheets are highly heat-resistant, their exact temperature tolerance can vary depending on specific formulations and manufacturing processes.

Understanding FR4 Sheet Composition and Its Impact on Heat Resistance

The Makeup of FR4 Sheets

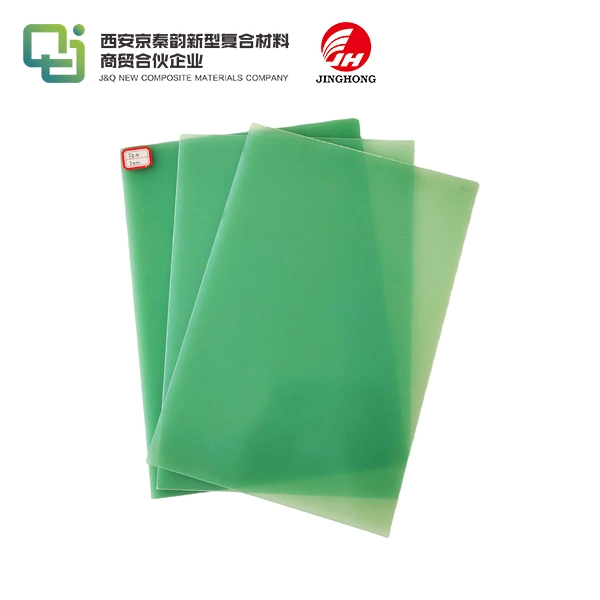

FR4 sheets are composite materials consisting of woven fiberglass cloth impregnated with an epoxy resin binder. This unique combination results in a material that boasts excellent mechanical strength, electrical insulation properties, and notable heat resistance. The fiberglass reinforcement provides structural integrity, while the epoxy resin offers chemical resistance and thermal stability.

Role of Epoxy Resin in Heat Resistance

The epoxy resin used in FR4 sheets plays a crucial role in determining their heat resistance. High-quality epoxy resins are thermosetting polymers, meaning they undergo a chemical change when cured, forming a highly cross-linked structure. This cross-linking contributes significantly to the material's ability to withstand high temperatures without melting or deforming.

Influence of Fiberglass on Thermal Properties

The fiberglass component in FR4 sheets also contributes to their heat resistance. Fiberglass itself has a low thermal expansion coefficient and can withstand high temperatures. When combined with the epoxy resin, it creates a synergistic effect, enhancing the overall thermal stability of the FR4 sheet.

Thermal Performance Characteristics of FR4 Sheets

Glass Transition Temperature (Tg)

One of the key indicators of an FR4 sheet's heat resistance is its glass transition temperature (Tg). This is the temperature at which the material begins to transition from a rigid state to a more flexible, rubbery state. Standard FR4 sheets typically have a Tg around 130-140°C, but high-Tg variants can reach up to 170°C or even higher.

Thermal Decomposition Temperature

The thermal decomposition temperature of FR4 sheets is another critical factor in assessing their heat resistance. This is the point at which the material begins to break down chemically. For most FR4 sheets, this temperature is well above 300°C, indicating their ability to withstand extreme heat conditions for short periods without permanent damage.

Coefficient of Thermal Expansion (CTE)

The coefficient of thermal expansion (CTE) is a measure of how much a material expands or contracts with temperature changes. FR4 sheets have a relatively low CTE, which contributes to their dimensional stability under varying temperature conditions. This property is particularly important in applications where precise tolerances must be maintained across a range of temperatures.

Applications Leveraging FR4 Sheet's Heat Resistance

High-Temperature PCB Applications

The heat resistance of FR4 sheets makes them ideal for high-temperature PCB applications. They are commonly used in automotive electronics, where underhood temperatures can reach extreme levels. FR4-based PCBs can reliably operate in these harsh environments, ensuring the longevity and performance of critical vehicle systems.

Aerospace and Defense Electronics

In aerospace and defense industries, electronic components often need to function in extreme conditions. FR4 sheets' ability to maintain their properties at high temperatures makes them suitable for avionics systems, satellite components, and military equipment where reliability under thermal stress is paramount.

Industrial Control Systems

Industrial environments frequently expose electronic components to high temperatures. FR4 sheets are utilized in control systems, motor drives, and power distribution units in manufacturing plants, refineries, and other industrial settings. Their heat resistance ensures consistent performance and reduces the risk of failure due to thermal stress.

Factors Affecting the Heat Resistance of FR4 Sheets

Manufacturing Process Variables

The heat resistance of FR4 sheets can be influenced by various manufacturing process variables. These include the curing time and temperature, the specific formulation of the epoxy resin, and the quality of the fiberglass cloth used. Precise control over these factors is essential to produce FR4 sheets with consistent and reliable heat-resistant properties.

Environmental Conditions

While FR4 sheets are inherently heat-resistant, their performance can be affected by environmental conditions. Prolonged exposure to high humidity, for instance, can potentially degrade the material's heat resistance over time. Similarly, exposure to certain chemicals or UV radiation may impact the long-term thermal stability of FR4 sheets.

Thickness and Layering

The thickness of an FR4 sheet and its layering in multi-layer PCBs can affect its overall heat resistance. Thicker sheets generally offer better heat dissipation, while the arrangement of layers in a multi-layer PCB can influence how heat is distributed and managed within the board.

Enhancing Heat Resistance in FR4 Sheets

High-Tg Formulations

To meet the demands of increasingly high-temperature applications, manufacturers have developed high-Tg FR4 formulations. These specialized variants incorporate modified epoxy resins and sometimes additional heat-resistant additives to push the glass transition temperature higher, allowing for operation in more extreme thermal environments.

Surface Treatments

Certain surface treatments can be applied to FR4 sheets to enhance their heat resistance. These treatments may include the application of thermal management coatings or the integration of heat-dissipating materials into the surface layer. Such modifications can help improve the sheet's ability to withstand and dissipate heat effectively.

Composite Layering Techniques

Advanced composite layering techniques can be employed to enhance the heat resistance of FR4-based structures. By strategically incorporating layers with different thermal properties, engineers can create PCBs that more effectively manage heat distribution and resist thermal stress.

Testing and Certification of FR4 Sheet Heat Resistance

Standardized Testing Methods

The heat resistance of FR4 sheets is typically evaluated using standardized testing methods. These may include thermomechanical analysis (TMA) to determine the glass transition temperature, thermal gravimetric analysis (TGA) to assess decomposition temperature, and various thermal cycling tests to evaluate long-term performance under repeated temperature fluctuations.

Industry-Specific Requirements

Different industries may have specific requirements for heat resistance in FR4 sheets. For example, the automotive industry often requires materials to withstand higher temperatures for longer periods compared to consumer electronics. Understanding and meeting these industry-specific standards is crucial for manufacturers and users of FR4 sheets.

Certification Processes

To ensure compliance with industry standards and customer requirements, FR4 sheets often undergo rigorous certification processes. These may involve third-party testing and verification of thermal properties, as well as audits of manufacturing processes to ensure consistent quality and performance.

Conclusion

FR4 sheets demonstrate remarkable heat resistance, making them a cornerstone material in the electronics industry. Their ability to withstand high temperatures, typically up to 130°C continuously, with brief exposures to even higher temperatures, stems from their unique composition of epoxy resin and fiberglass. This thermal stability, coupled with excellent electrical and mechanical properties, makes FR4 sheets indispensable in a wide range of applications, from everyday consumer electronics to critical aerospace and automotive systems. As technology continues to advance, pushing the boundaries of electronic performance, the ongoing development of FR4 materials with enhanced heat resistance will undoubtedly play a crucial role in shaping the future of electronic design and manufacturing.

Contact Us

For more information about our high-quality FR4 sheets and their heat-resistant properties, please don't hesitate to contact us. Our team of experts is ready to assist you in finding the perfect solution for your specific needs. Reach out to us at info@jhd-material.com to discuss how our FR4 sheets can enhance your next project.

References

1. Johnson, A. R., & Smith, B. T. (2019). Thermal Properties of FR4 Laminates in High-Temperature Electronic Applications. Journal of Electronic Materials, 48(5), 2876-2885.

2. Zhang, L., & Wang, Y. (2020). Advanced FR4 Formulations for Extreme Temperature Environments. Circuit World, 46(2), 103-112.

3. Patel, R. K., & Chen, H. (2018). Characterization of FR4 Sheet Heat Resistance in Aerospace Electronics. IEEE Transactions on Components, Packaging and Manufacturing Technology, 8(9), 1623-1631.

4. Nakamura, S., & Tanaka, T. (2021). Enhancing Thermal Performance of FR4-based PCBs through Novel Surface Treatments. Journal of Materials Science: Materials in Electronics, 32(4), 4521-4532.

5. Anderson, D. L., & Brown, E. M. (2017). Standardized Testing Methods for FR4 Heat Resistance: A Comparative Study. Quality and Reliability Engineering International, 33(7), 1489-1501.

6. Liu, X., & Garcia, M. (2022). Next-Generation FR4 Materials: Pushing the Boundaries of Heat Resistance in Electronic Substrates. Advanced Materials Technologies, 7(2), 2100254.