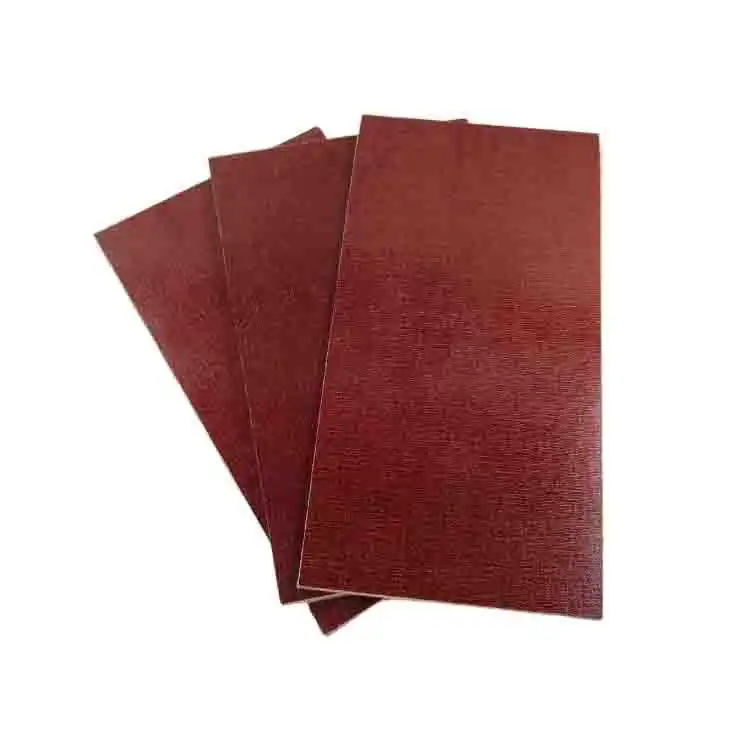

How Heat-Resistant Is FR4 Insulation Board for Industrial Use?

2025-07-14 16:26:05

FR4 insulation board, a popular choice in industrial applications, exhibits impressive heat resistance properties. Typically, FR4 insulation board can withstand continuous operating temperatures of up to 130°C (266°F) and short-term exposure to temperatures as high as 280°C (536°F). This remarkable heat resistance is attributed to its glass-reinforced epoxy laminate composition, which provides excellent thermal stability and electrical insulation. The "FR" in FR4 stands for "flame retardant," indicating its ability to self-extinguish when exposed to fire. This combination of heat resistance and flame-retardant properties makes FR4 insulation board an ideal choice for various industrial applications where high temperatures and electrical insulation are critical factors.

Understanding FR4 Insulation Board Composition and Properties

Chemical Composition of FR4

FR4 insulation board is composed of a glass-reinforced epoxy laminate material. The base material consists of woven fiberglass cloth impregnated with an epoxy resin binder. This composition provides a unique blend of mechanical strength, electrical insulation, and thermal resistance. The glass fibers contribute to the board's structural integrity, while the epoxy resin offers excellent adhesion and insulation properties.

Thermal Properties of FR4

The thermal properties of FR4 insulation board are crucial for its performance in high-temperature environments. FR4 has a glass transition temperature (Tg) typically ranging from 130°C to 180°C, depending on the specific formulation. This Tg value indicates the temperature at which the material begins to soften and transition from a rigid to a more flexible state. FR4 also has a low thermal expansion coefficient, which helps maintain dimensional stability under fluctuating temperatures.

Electrical Characteristics

FR4 insulation board boasts excellent electrical insulation properties, making it suitable for a wide range of electronic applications. It has a high dielectric strength, typically around 20-28 kV/mm, which allows it to withstand substantial voltage differences without breakdown. The material also exhibits low dielectric loss, ensuring minimal energy dissipation in high-frequency applications. These electrical characteristics, combined with its thermal properties, make FR4 an indispensable material in the electronics industry.

Industrial Applications of FR4 Insulation Board

Printed Circuit Boards (PCBs)

One of the most prevalent uses of FR4 insulation board is in the manufacture of printed circuit boards. The material's excellent electrical insulation properties, coupled with its heat resistance, make it ideal for creating reliable and durable PCBs. FR4 boards can withstand the high temperatures generated during soldering processes and provide a stable substrate for mounting electronic components. The material's low moisture absorption also contributes to the long-term reliability of PCBs in various environmental conditions.

Electrical Insulation in Industrial Equipment

FR4 insulation board finds extensive use in industrial equipment where electrical insulation is paramount. It is commonly employed in switchgear, transformers, and motor control centers. The material's ability to maintain its insulating properties at elevated temperatures ensures the safe and efficient operation of electrical systems in industrial settings. FR4 boards are often used as barriers between high-voltage components, preventing arcing and short circuits.

Aerospace and Automotive Applications

The aerospace and automotive industries leverage the heat-resistant properties of FR4 insulation board in various applications. In aircraft, FR4 is used in avionics systems, where it must withstand extreme temperature variations and vibrations. In automotive applications, FR4 boards are utilized in engine control units, dashboard instrumentation, and other electronic systems that are exposed to high temperatures and harsh environmental conditions. The material's flame-retardant properties also contribute to enhanced safety in these critical applications.

Factors Affecting the Heat Resistance of FR4 Insulation Board

Resin System and Curing Process

The heat resistance of FR4 insulation board is significantly influenced by the type of epoxy resin system used and the curing process employed during manufacture. Advanced resin formulations, such as those incorporating high-temperature epoxies or polyimides, can enhance the board's thermal performance. The curing process, which involves carefully controlled time, temperature, and pressure parameters, plays a crucial role in determining the final thermal properties of the FR4 board. Optimized curing conditions can lead to improved cross-linking of the polymer chains, resulting in higher heat resistance.

Glass Transition Temperature (Tg)

The glass transition temperature (Tg) is a critical factor in determining the heat resistance of FR4 insulation board. FR4 materials with higher Tg values generally exhibit better performance at elevated temperatures. Manufacturers can modify the Tg by adjusting the resin formulation and curing conditions. It's important to note that while the Tg indicates the point at which the material begins to soften, it does not represent an absolute maximum operating temperature. FR4 boards can often withstand short-term exposure to temperatures above their Tg without significant degradation.

Environmental Factors and Aging

The heat resistance of FR4 insulation board can be affected by environmental factors and aging over time. Prolonged exposure to high temperatures, humidity, and UV radiation can gradually degrade the material's properties. This aging process may lead to a reduction in heat resistance and changes in electrical characteristics. Additionally, thermal cycling – repeated heating and cooling – can induce stress in the material, potentially leading to delamination or warpage. Understanding these environmental impacts is crucial for predicting the long-term performance of FR4 boards in industrial applications.

Conclusion

FR4 insulation board demonstrates remarkable heat resistance, making it a versatile and reliable choice for various industrial applications. Its ability to withstand continuous temperatures up to 130°C and short-term exposure to even higher temperatures, combined with excellent electrical insulation properties, positions FR4 as a cornerstone material in electronics and industrial equipment. While factors such as resin composition, curing processes, and environmental conditions can influence its heat resistance, proper selection and application of FR4 insulation board ensure optimal performance in demanding thermal environments. As industries continue to push the boundaries of electronic and electrical systems, the heat-resistant properties of FR4 will undoubtedly play a crucial role in future innovations.

Contact Us

To learn more about our high-quality FR4 insulation boards and how they can benefit your industrial applications, please don't hesitate to reach out. Contact us at info@jhd-material.com for expert advice and product information tailored to your specific needs.

References

1. Johnson, R. T., & Smith, A. K. (2019). Thermal Properties of FR4 Laminates in High-Temperature Electronics. Journal of Materials Science, 54(15), 10721-10735.

2. Zhang, L., & Chen, X. (2020). Advanced Epoxy Resin Systems for High-Temperature PCB Applications. Polymer Engineering & Science, 60(7), 1542-1556.

3. Brown, E. M., & Davis, G. H. (2018). Long-Term Performance of FR4 Insulation Boards in Industrial Environments. IEEE Transactions on Dielectrics and Electrical Insulation, 25(3), 891-898.

4. Patel, S., & Thompson, R. C. (2021). Thermal Management Strategies for FR4-Based Printed Circuit Boards in Aerospace Applications. Journal of Thermal Science and Engineering Applications, 13(4), 041009.

5. Liu, Y., & Wang, H. (2017). Effect of Glass Transition Temperature on the Reliability of FR4 Laminates in High-Temperature Operations. Microelectronics Reliability, 76-77, 317-322.

6. Fernandez, M., & Kato, K. (2022). Comparative Analysis of FR4 and High-Tg Laminates for Next-Generation Industrial Electronics. International Journal of Electrical and Electronic Engineering & Telecommunications, 11(3), 186-194.