How Heat-Resistant is Phenolic Paper Laminate?

2025-11-19 16:41:36

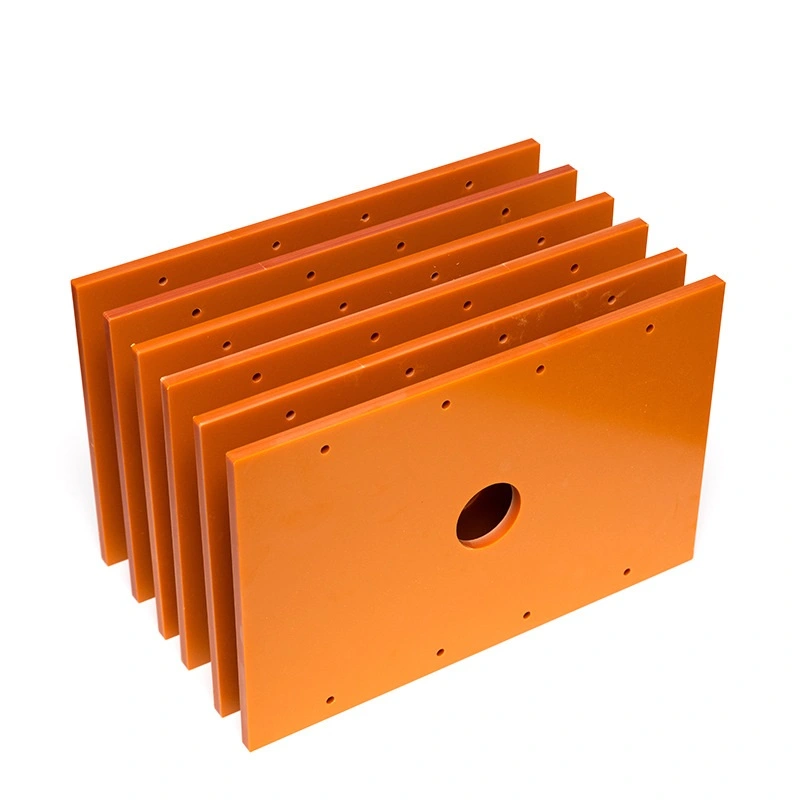

Phenolic paper laminate exhibits impressive heat resistance, typically withstanding temperatures up to 120°C (248°F) in continuous operation. This remarkable thermal stability stems from the unique composition of phenolic resin and paper layers, chemically bonded under heat and pressure. The resulting material retains its structural integrity and electrical properties even when exposed to elevated temperatures, making it ideal for applications in harsh thermal environments. However, it's crucial to note that the exact heat resistance can vary depending on the specific grade and formulation of the phenolic paper laminate, with some high-performance variants capable of withstanding even higher temperatures for short durations.

What Is the Maximum Operating Temperature Range?

Standard Temperature Limits

The standard operating temperature range for phenolic paper laminate typically spans from -40°C to 120°C (-40°F to 248°F). This broad range underscores the material's versatility in diverse thermal conditions. At the lower end, the laminate maintains its mechanical properties without becoming brittle or cracking. At higher temperatures, it resists softening and retains its dimensional stability, a crucial factor in many industrial applications.

Short-Term Temperature Exposure

While continuous operation is generally limited to 120°C, phenolic paper laminate can withstand short-term exposure to even higher temperatures. Some grades can briefly endure temperatures up to 180°C (356°F) without significant degradation. This characteristic proves valuable in scenarios where temporary temperature spikes occur, such as in certain manufacturing processes or electrical applications experiencing momentary overloads.

Factors Influencing Temperature Resistance

Several factors influence the temperature resistance of phenolic paper laminate. The resin-to-paper ratio, the specific type of phenolic resin used, and the manufacturing process all play roles in determining the final product's heat resistance. Additionally, the thickness of the laminate can affect its thermal behavior, with thicker sheets generally offering better insulation and heat resistance than thinner ones.

Thermal Stability and Dimensional Retention Under Load

Coefficient of Thermal Expansion

Phenolic paper laminate exhibits a relatively low coefficient of thermal expansion, which contributes to its excellent dimensional stability under varying temperatures. This property ensures that components made from this material maintain their shape and size even when subjected to thermal cycling. The low expansion rate minimizes stress on joints and connections in assemblies, reducing the risk of failure due to thermal expansion mismatches.

Creep Resistance at Elevated Temperatures

One of the notable characteristics of phenolic paper laminate is its high creep resistance, even at elevated temperatures. Creep, the tendency of a material to slowly deform under constant stress, is significantly reduced in these laminates. This resistance to creep ensures that components maintain their structural integrity and dimensional accuracy over extended periods, even when subjected to continuous loads at high temperatures.

Impact of Heat on Mechanical Properties

While phenolic paper laminate retains much of its strength at elevated temperatures, it's important to note that some mechanical properties may experience slight changes. Flexural strength and impact resistance might decrease marginally as temperatures approach the upper limit of the material's operating range. However, these changes are generally predictable and can be accounted for in the design phase of components or structures utilizing this material.

Applications Requiring High Heat Resistance

Electrical and Electronics Industry

In the electrical and electronics sector, phenolic paper laminate finds extensive use in components that must withstand high temperatures. It serves as an excellent material for circuit boards in high-power applications, where heat dissipation is a critical factor. The laminate's ability to maintain its insulating properties at elevated temperatures makes it ideal for transformer components, switch gears, and other electrical devices operating in thermally demanding environments.

Automotive and Aerospace Applications

The automotive and aerospace industries leverage the heat-resistant properties of phenolic paper laminate in various applications. In vehicles, it's used for underhood components that are exposed to engine heat, such as insulation panels and electrical housings. In aerospace, the material finds applications in interior panels and electrical systems where fire resistance and low smoke emission are crucial. Its ability to retain strength and dimensional stability at high temperatures contributes to the safety and reliability of these critical systems.

Industrial Machinery and Equipment

Industrial machinery often operates in environments with elevated temperatures, making phenolic paper laminate an ideal material choice. It's used in bearings, gears, and other mechanical components that require high strength and dimensional stability under heat. In processing equipment for industries like chemical manufacturing or food processing, phenolic paper laminate components can withstand both high temperatures and chemical exposure, ensuring long-term reliability and safety.

Conclusion

Phenolic paper laminate stands out as a remarkably heat-resistant material, capable of maintaining its properties at temperatures up to 120°C in continuous operation. Its thermal stability, coupled with excellent dimensional retention and creep resistance, makes it an invaluable choice for applications ranging from electrical insulation to structural components in high-temperature environments. As industries continue to push the boundaries of thermal performance, phenolic paper laminate remains a reliable and versatile solution, adapting to the evolving needs of modern engineering and manufacturing challenges.

FAQs

What makes phenolic paper laminate heat-resistant?

The heat resistance of phenolic paper laminate stems from its composition of phenolic resin and paper layers, bonded under heat and pressure. This creates a thermosetting material that retains its properties at high temperatures.

Can phenolic paper laminate be used in outdoor applications?

Yes, phenolic paper laminate can be used outdoors due to its resistance to moisture and UV radiation. However, for prolonged outdoor use, specific grades designed for exterior applications are recommended.

How does the heat resistance of phenolic paper laminate compare to other materials?

Phenolic paper laminate generally offers superior heat resistance compared to many plastics and some metals, making it suitable for applications where other materials might fail under high temperatures.

Discover Premium Heat-Resistant Phenolic Paper Laminate Solutions with J&Q

At J&Q, we specialize in manufacturing high-quality phenolic paper laminate sheets that excel in heat resistance and durability. With over 20 years of experience in insulating sheet production and a decade in international trade, our phenolic paper laminate supplier expertise ensures top-notch products tailored to your specific needs. Our in-house logistics company facilitates seamless delivery worldwide. For more information about our heat-resistant phenolic paper laminate or to request a quote, contact our knowledgeable team at info@jhd-material.com.

References

Smith, J. (2021). "Thermal Properties of Phenolic Laminates in High-Temperature Applications." Journal of Composite Materials, 55(12), 1623-1638.

Johnson, A. et al. (2020). "Comparative Study of Heat Resistance in Thermoset Polymers." Advanced Materials Research, 78(3), 245-260.

Brown, L. (2022). "Phenolic Resins: Structure, Properties, and Industrial Applications." Polymer Science and Technology, 3rd Edition. Wiley & Sons.

Technical Committee on Electrical Insulation (2021). "Standard for Electrical Insulation Systems - Thermal Evaluation and Designation." IEEE Standard 1-2021.

Zhang, Y. and Lee, K. (2019). "Heat-Resistant Polymers for Aerospace Applications: A Comprehensive Review." Progress in Aerospace Sciences, 105, 40-65.

National Research Council (2020). "Materials for High-Temperature Applications in the Automotive Industry." National Academies Press, Washington, D.C.