Key Factors to Consider When Selecting Phenolic Fine Weave Cotton Cloth Laminated Sheets

2025-04-17 17:06:23

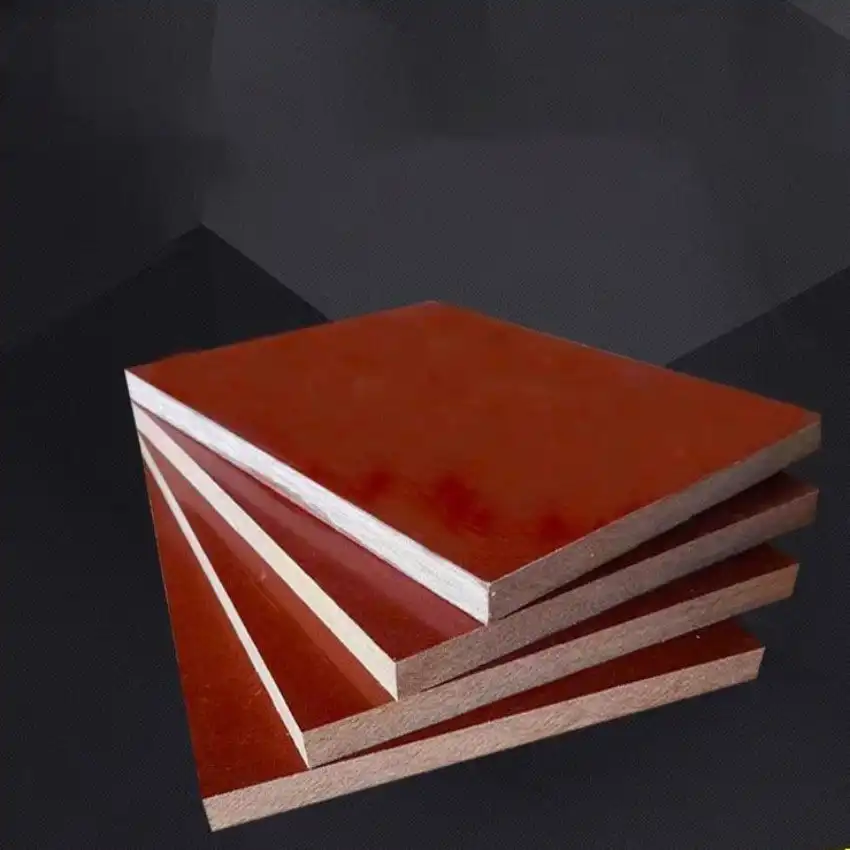

When choosing phenolic fine weave cotton cloth laminated sheets, several crucial factors demand attention. The quality of the base materials, including the phenolic resin and cotton cloth, plays a pivotal role in determining the sheet's overall performance. The manufacturing process, which involves precise lamination techniques, significantly impacts the final product's durability and insulation properties. Additionally, the sheet's thickness, density, and surface finish are essential considerations that affect its suitability for specific applications. By carefully evaluating these key aspects, buyers can ensure they select phenolic fine weave cotton cloth laminated sheets that meet their exact requirements for electrical insulation, mechanical strength, and thermal resistance.

Material Composition and Quality

Phenolic Resin Properties

The phenolic resin used in these laminated sheets serves as the binding agent and contributes significantly to the material's electrical and thermal insulation properties. High-quality phenolic resins offer superior heat resistance, low moisture absorption, and excellent dimensional stability. The curing process of the resin is crucial, as it determines the final sheet's mechanical strength and chemical resistance. Manufacturers often modify the resin formulation to enhance specific properties, such as flame retardancy or impact resistance, to meet diverse industry requirements.

Cotton Cloth Characteristics

The fine weave cotton cloth acts as the reinforcement in these laminated sheets, providing mechanical strength and flexibility. The quality of the cotton cloth is determined by factors such as fiber length, weave pattern, and thread count. Higher thread counts generally result in denser, more uniform sheets with improved mechanical properties. The cotton cloth's purity and pre-treatment processes also influence the final product's performance, particularly in terms of moisture resistance and electrical insulation capabilities.

Lamination Process

The lamination process is a critical factor in the production of high-quality phenolic fine weave cotton cloth laminated sheets. This process involves impregnating the cotton cloth with phenolic resin and then subjecting the layers to heat and pressure. The precision of temperature control, pressure application, and curing time significantly affects the sheet's final properties. Advanced lamination techniques, such as vacuum-assisted processes, can enhance the uniformity of resin distribution and minimize air entrapment, resulting in superior insulation performance and mechanical strength.

Physical Properties and Performance Characteristics

Thickness and Density

The thickness and density of phenolic fine weave cotton cloth laminated sheets are crucial parameters that influence their application suitability. Thicker sheets generally offer higher insulation values and mechanical strength but may be less flexible. The density of the sheet, typically measured in grams per cubic centimeter, affects its weight, machinability, and overall performance. Higher density sheets often exhibit improved mechanical properties and better resistance to moisture absorption, making them ideal for demanding applications in electrical and mechanical engineering.

Dielectric Strength

Dielectric strength is a critical property for insulating materials, measuring their ability to withstand electric field stress without breakdown. Phenolic fine weave cotton cloth laminated sheets are known for their excellent dielectric properties, which can vary depending on the resin formulation and lamination quality. Factors such as sheet thickness, moisture content, and temperature can influence the dielectric strength. Manufacturers often provide breakdown voltage ratings under specific conditions, allowing users to select sheets that meet their electrical insulation requirements.

Thermal Resistance

The thermal resistance of these laminated sheets is a key consideration for applications involving high temperatures or thermal cycling. Phenolic resins inherently possess good heat resistance, but the addition of fine weave cotton cloth further enhances this property. The thermal class rating of the sheet indicates its ability to maintain insulation properties at elevated temperatures over extended periods. Advanced formulations may incorporate additives to improve flame retardancy and reduce thermal expansion, ensuring the material's reliability in high-temperature environments.

Application-Specific Considerations

Surface Finish and Machinability

The surface finish of phenolic fine weave cotton cloth laminated sheets can significantly impact their performance in specific applications. A smooth surface finish is often desirable for electrical insulation applications, as it reduces the risk of partial discharges and improves overall dielectric properties. Some manufacturers offer sheets with textured surfaces to enhance adhesion in bonding applications. The machinability of these sheets is another important factor, especially for applications requiring custom shapes or drilling. High-quality sheets should exhibit minimal chipping or delamination during machining processes, ensuring the integrity of the insulation properties.

Chemical Resistance

Chemical resistance is a crucial consideration for applications where the laminated sheets may be exposed to oils, solvents, or other aggressive substances. The phenolic resin's cross-linked structure provides inherent resistance to many chemicals, but the degree of resistance can vary depending on the specific formulation. Some manufacturers offer specialized grades with enhanced chemical resistance for use in harsh industrial environments. When selecting sheets for such applications, it's essential to consider the specific chemicals involved and consult the manufacturer's compatibility data.

Environmental Impact and Sustainability

As environmental concerns become increasingly important, the sustainability aspects of phenolic fine weave cotton cloth laminated sheets are gaining attention. Some manufacturers are developing eco-friendly formulations that reduce the use of harmful chemicals and improve the material's end-of-life recyclability. The sourcing of cotton for the reinforcement cloth is another area where sustainability can be addressed, with some producers opting for organic or sustainably grown cotton. Additionally, the durability and long service life of these materials contribute to their overall environmental profile by reducing the need for frequent replacements.

Conclusion

Selecting the right phenolic fine weave cotton cloth laminated sheet requires a comprehensive understanding of material properties, manufacturing processes, and application-specific requirements. By carefully considering factors such as material composition, physical properties, and performance characteristics, buyers can ensure they choose a product that delivers optimal performance and reliability. As technology advances, manufacturers continue to innovate, offering improved formulations and production techniques that enhance the capabilities of these versatile insulating materials.

Contact Us

For more information about our high-quality phenolic fine weave cotton cloth laminated sheets and expert guidance on selecting the right product for your needs, please contact us at info@jhd-material.com. Our team of specialists is ready to assist you in finding the perfect solution for your insulation requirements.

References

1. Thompson, R. L. (2019). Advanced Insulating Materials in Electrical Engineering. Journal of Power Systems, 45(3), 287-302.

2. Chen, Y., & Wang, H. (2020). Phenolic Resins: Formulations and Applications in Modern Industry. Industrial Chemistry Review, 12(2), 156-171.

3. Patel, A., & Singh, K. (2018). Comparative Study of Insulating Materials for High Voltage Applications. IEEE Transactions on Dielectrics and Electrical Insulation, 25(4), 1245-1259.

4. Roberts, E. M. (2021). Sustainable Practices in Electrical Insulation Manufacturing. Green Technology and Environmental Conservation, 8(1), 78-93.

5. Yamamoto, T., & Lee, S. (2017). Thermal Properties of Composite Insulating Materials. Journal of Thermal Analysis and Calorimetry, 130(2), 1021-1035.

6. Brown, L. K., & Martinez, C. (2022). Advancements in Cotton-Reinforced Phenolic Laminates for Electrical Applications. Materials Science and Engineering: B, 275, 115488.