Navigating the World of PCB Materials with FR4 Epoxy Sheets

2025-08-28 17:08:16

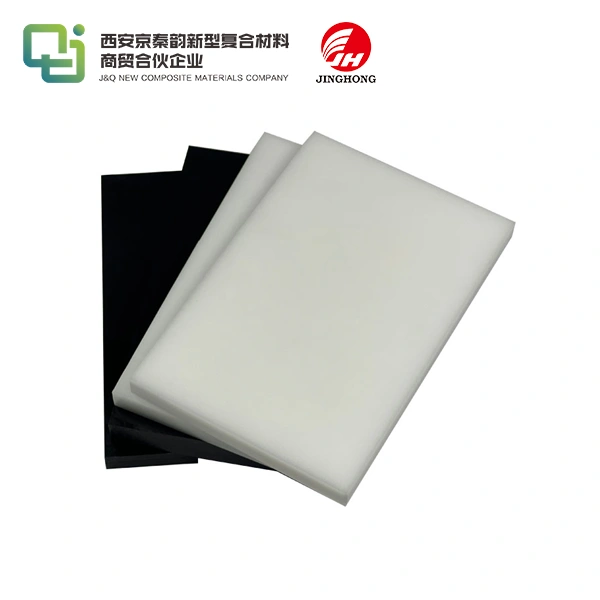

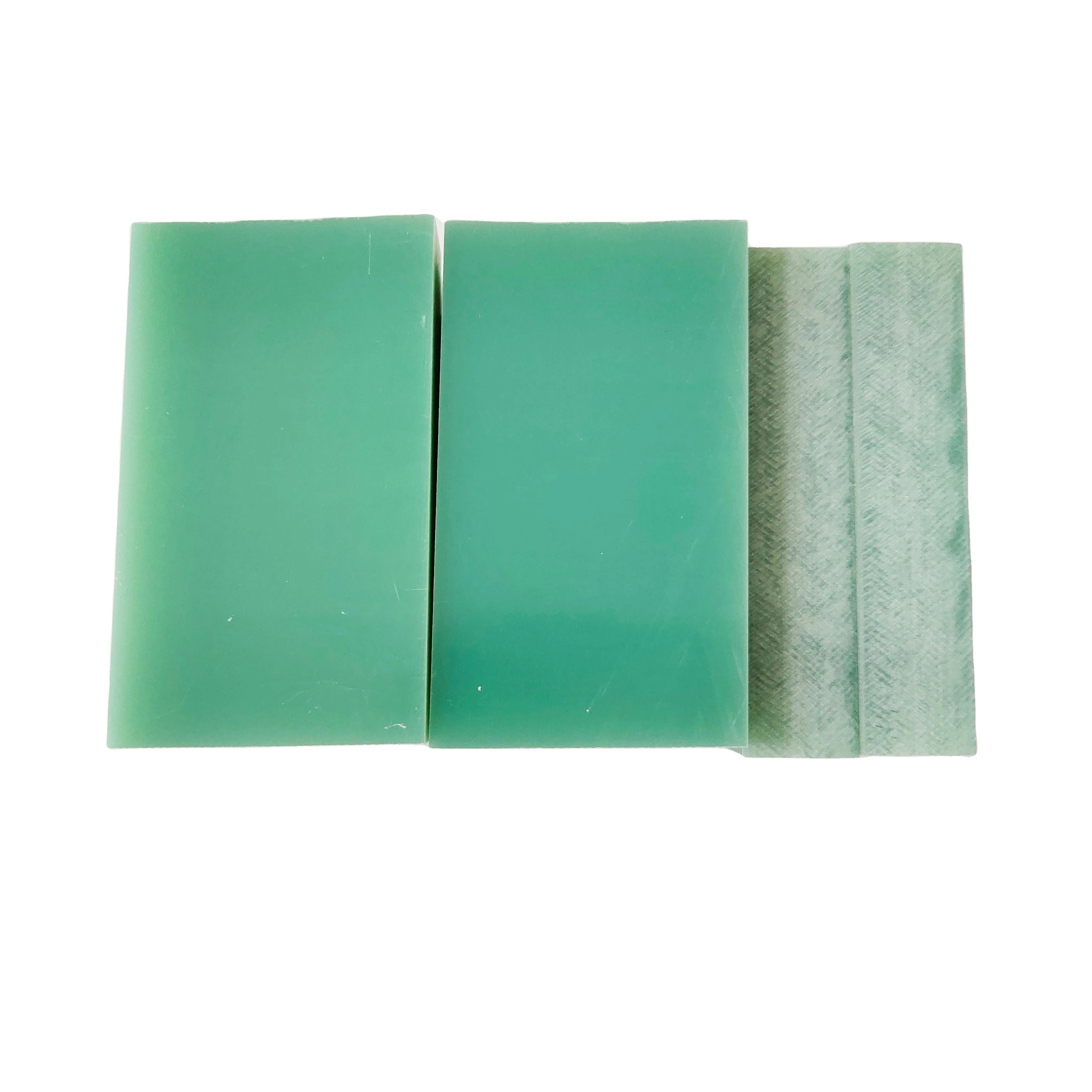

In the realm of printed circuit board (PCB) manufacturing, FR4 epoxy sheets stand as a cornerstone material, revolutionizing the industry with their exceptional properties. These versatile sheets, composed of fiberglass-reinforced epoxy resin, offer a perfect balance of electrical insulation, mechanical strength, and cost-effectiveness. As we delve into the intricacies of FR4 epoxy sheets, we'll uncover why they've become the go-to choice for PCB manufacturers worldwide. From their flame-retardant characteristics to their adaptability in multi-layer designs, FR4 sheets continue to shape the landscape of electronic device production, ensuring reliability and performance across a wide range of applications.

Why Is FR4 the Standard Material for PCB Manufacturing?

Unparalleled Electrical Properties

FR4 epoxy sheets are widely recognized for their outstanding electrical insulation, which is fundamental in ensuring PCB performance. With a high dielectric strength, FR4 prevents current leakage between densely packed conductive layers, preserving signal clarity and minimizing electromagnetic interference. This capability is particularly important for modern electronics that rely on high-speed data transmission and compact circuit layouts. By maintaining stable electrical characteristics under different operating conditions, FR4 helps guarantee consistent functionality, making it indispensable for applications ranging from consumer gadgets to advanced communication systems.

Mechanical Robustness

The mechanical strength of FR4 sheets comes from their fiberglass reinforcement, which provides resilience against bending, impact, and vibration. This robustness ensures that PCBs can endure the stresses of drilling, soldering, and component mounting during production, as well as the physical demands of everyday use. Such durability greatly reduces the risk of board fractures, layer separation, or other structural failures. By extending the functional lifespan of electronic devices, FR4 minimizes costly repairs and replacements, making it a reliable material choice across numerous electronic applications and industries.

Thermal Stability

FR4 epoxy sheets also excel in thermal stability, retaining their structural and electrical properties across wide temperature ranges. This resistance to thermal stress is essential in environments where components produce significant heat or where devices operate continuously. The material’s low coefficient of thermal expansion reduces the risk of warping, delamination, or cracking, which could otherwise compromise circuit reliability. By safeguarding solder joints and copper traces under heat, FR4 ensures long-term durability, enabling electronics to maintain performance in demanding applications such as automotive, aerospace, and industrial systems.

Advantages of FR4 Sheets in Multi-Layer PCB Construction

Enhanced Design Flexibility

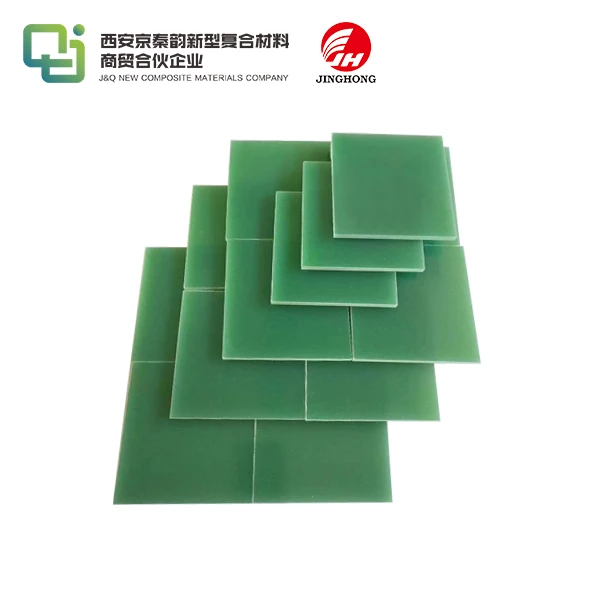

FR4 epoxy sheets provide exceptional flexibility in multi-layer PCB construction, giving designers the freedom to integrate numerous interconnected layers within a compact footprint. This capability is essential for developing modern electronics that demand higher functionality while maintaining smaller dimensions. The material’s stable dielectric properties across all layers ensure consistent signal propagation and reliable impedance control, which are critical in high-speed circuits. By supporting intricate layouts, FR4 sheets allow engineers to optimize space, performance, and efficiency in both consumer and industrial electronic devices.

Cost-Effective Scaling

The extensive use of FR4 sheets throughout the PCB industry has significantly lowered production costs, making them a practical option for projects of any scale. Their availability in multiple thicknesses and sheet sizes allows manufacturers to adapt designs quickly while minimizing material waste. Small-scale prototyping benefits from affordability and accessibility, while large-volume production achieves greater economies of scale. This cost efficiency does not compromise durability or performance, enabling businesses to deliver high-quality electronic products at competitive prices while maintaining consistency in manufacturing standards.

Compatibility with Advanced Manufacturing Techniques

FR4 epoxy sheets are highly versatile and fully compatible with advanced PCB fabrication processes, including precision methods such as laser drilling, via-in-pad, and sequential lamination. This adaptability supports the production of high-density interconnect (HDI) boards, which are crucial for compact devices requiring complex routing solutions. FR4’s machinability and stable performance ensure that these advanced processes can be executed without material failure. As a result, manufacturers can meet the increasing demands of modern electronics, producing smaller, faster, and more efficient devices that integrate cutting-edge technologies.

Ensuring Quality and Performance with FR4 Epoxy-Based PCBs

Rigorous Material Selection

To guarantee the highest quality FR4 epoxy-based PCBs, manufacturers must carefully select materials that meet industry standards and specifications. This involves evaluating factors such as glass transition temperature (Tg), dielectric constant, and dissipation factor to ensure optimal performance in the intended application. Choosing the right grade of FR4 material is crucial for achieving the desired balance of electrical, thermal, and mechanical properties.

Precision Manufacturing Processes

The production of high-performance FR4 PCBs relies on precise manufacturing processes. This includes accurate lamination techniques to ensure proper bonding between layers, controlled drilling to maintain hole quality, and meticulous copper etching to achieve fine-line circuitry. Advanced quality control measures, such as automated optical inspection (AOI) and electrical testing, are essential for identifying and rectifying any defects before the boards are assembled.

Environmental Considerations

While FR4 epoxy sheets offer excellent performance, it's important to consider their environmental impact. Many manufacturers are now exploring eco-friendly alternatives and recycling processes for FR4 materials to reduce waste and minimize the carbon footprint of PCB production. Advancements in halogen-free FR4 formulations are also addressing concerns about the release of harmful substances during disposal or recycling.

Conclusion

FR4 epoxy sheets have fundamentally transformed the PCB manufacturing landscape, offering a robust and versatile foundation for electronic devices across industries. Their unique combination of electrical insulation, mechanical strength, and thermal stability continues to make them the material of choice for PCB designers and manufacturers. As technology evolves, FR4 materials are likely to adapt, incorporating new innovations to meet the ever-increasing demands of modern electronics. By understanding the properties and advantages of FR4 epoxy sheets, engineers and manufacturers can harness their full potential to create reliable, high-performance PCBs that drive innovation in the electronics industry.

Contact Us

Ready to elevate your PCB designs with high-quality FR4 epoxy sheets? Contact our expert team at info@jhd-material.com for personalized guidance and superior materials that will take your electronic projects to the next level.

References

1. Coombs, C. F. (2021). Printed Circuits Handbook. McGraw-Hill Education.

2. Jawad, S. K. (2019). Advanced Materials for Printed Circuit Boards: Fundamentals and Applications. Springer.

3. Tummala, R. R. (2020). Fundamentals of Microsystems Packaging. McGraw-Hill Education.

4. IPC-4101: Specification for Base Materials for Rigid and Multilayer Printed Boards. (2018). IPC.

5. Ghaffarian, R. (2022). Reliability of Electronic Packages and Semiconductor Devices. Springer.

6. Fjelstad, J. (2020). Flexible Circuit Technology. BR Publishing.