Optimal Uses for Phenolic Cotton Sheets in Various Industries

2025-08-27 16:36:22

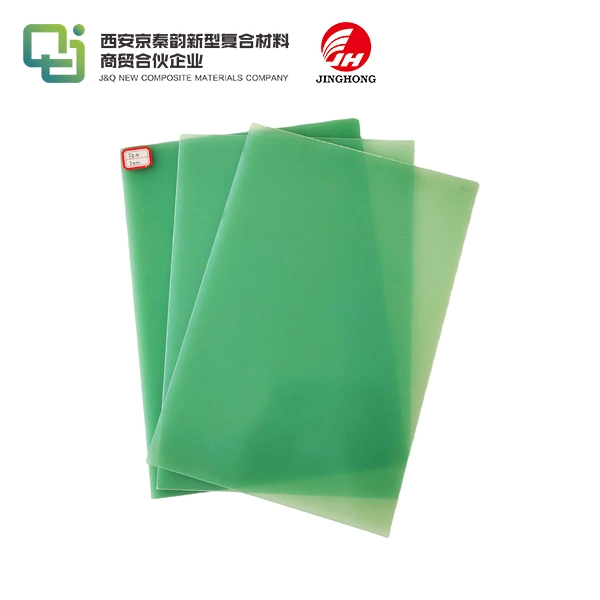

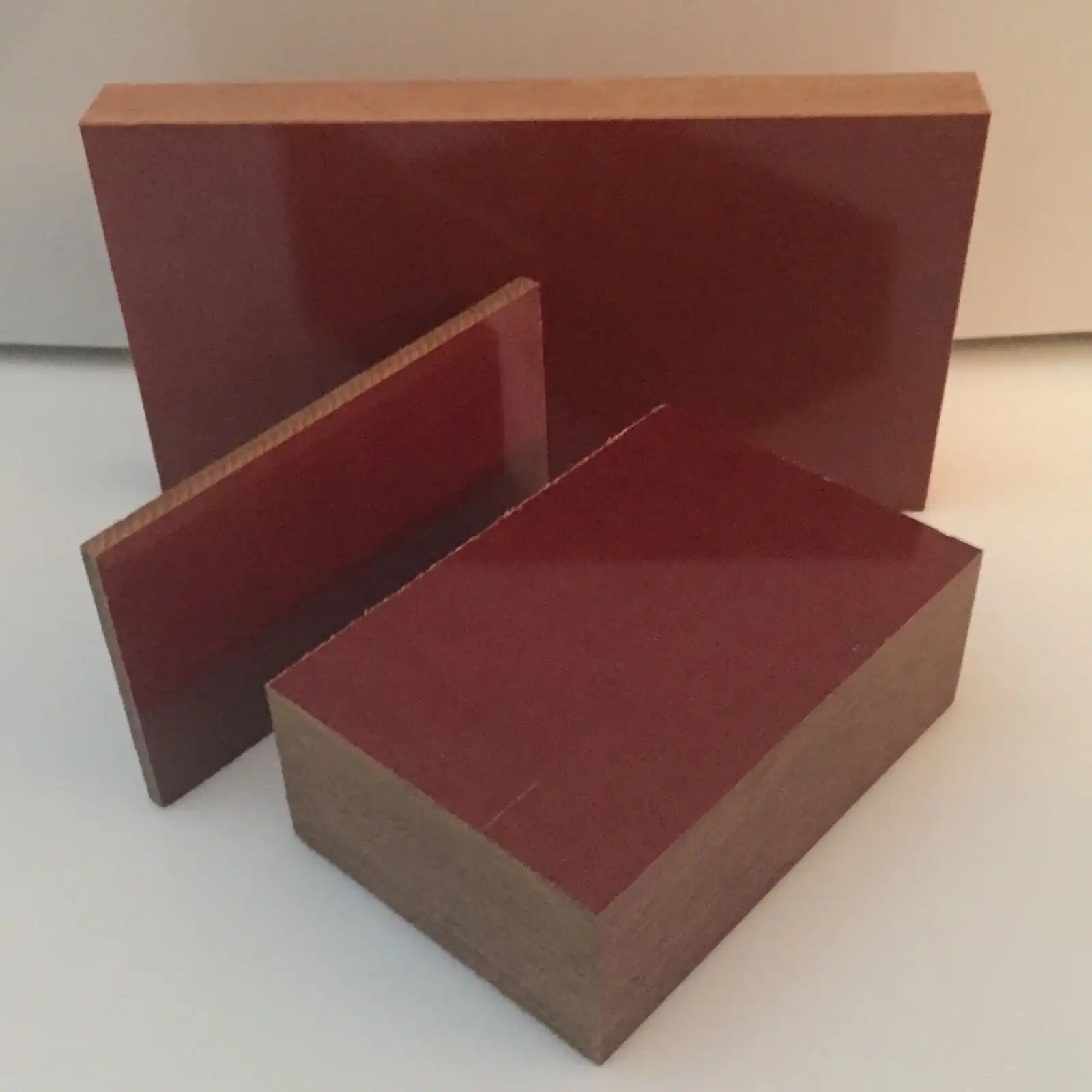

Phenolic cotton sheets have become indispensable in numerous industrial applications due to their exceptional properties and versatility. These composite materials, created by impregnating cotton fabric with phenolic resin and curing under heat and pressure, offer a unique combination of strength, durability, and electrical insulation. Their widespread adoption spans across mechanical engineering, electrical systems, automotive manufacturing, aerospace technology, and beyond. The optimal uses of phenolic cotton sheets are found in applications requiring high mechanical strength, excellent electrical insulation, chemical resistance, and dimensional stability. From heavy-duty components in industrial machinery to critical parts in aircraft and automobiles, these sheets provide reliable performance in demanding environments, making them a preferred choice for engineers and manufacturers across various sectors.

Why Are Phenolic Cotton Sheets Widely Used in Mechanical Engineering?

Superior Mechanical Properties

Phenolic cotton sheets exhibit remarkable mechanical strength and rigidity, making them ideal for numerous applications in mechanical engineering. Their high compressive strength allows them to withstand substantial loads without deformation, while their excellent impact resistance ensures durability in high-stress environments. These properties make phenolic cotton sheets an optimal choice for manufacturing gears, bearings, and other components subject to constant wear and tear.

Exceptional Machinability

One of the key advantages of phenolic cotton sheets in mechanical engineering is their exceptional machinability. These sheets can be easily cut, drilled, and shaped using standard woodworking tools, allowing for precise fabrication of complex parts. This attribute significantly reduces production time and costs, making phenolic cotton sheets a preferred material for prototyping and small-scale production runs in mechanical engineering applications.

Thermal and Chemical Resistance

Phenolic cotton sheets demonstrate impressive resistance to heat and chemicals, further expanding their utility in mechanical engineering. Their ability to maintain structural integrity at elevated temperatures makes them suitable for components in high-temperature environments. Additionally, their resistance to a wide range of chemicals ensures longevity in applications exposed to corrosive substances, such as industrial machinery and chemical processing equipment.

Applications of Phenolic Cotton Sheets in Automotive and Aerospace

Lightweight Structural Components

In the automotive and aerospace industries, where weight reduction is crucial for improved fuel efficiency and performance, phenolic cotton sheets offer an excellent solution. These sheets provide high strength-to-weight ratios, making them ideal for manufacturing lightweight structural components. From interior panels in automobiles to non-load-bearing structures in aircraft, phenolic cotton sheets contribute to overall weight reduction without compromising on strength and durability.

Electrical Insulation in Vehicle Systems

The superior electrical insulation properties of phenolic cotton sheets make them invaluable in automotive and aerospace electrical systems. They are commonly used in the production of terminal boards, switchgear components, and insulating barriers in various electrical assemblies. Their ability to maintain dielectric strength under varying environmental conditions ensures reliable performance in critical electrical systems, enhancing safety and functionality in vehicles and aircraft.

Thermal Management Solutions

Phenolic cotton sheets play a crucial role in thermal management solutions for automotive and aerospace applications. Their low thermal conductivity makes them effective insulators, helping to protect sensitive components from heat exposure. In aerospace, these sheets are often utilized in thermal protection systems, contributing to the overall safety and efficiency of aircraft. Their ability to withstand high temperatures without degradation ensures long-term reliability in demanding thermal environments.

Cost-Effectiveness and Efficiency of Phenolic Cotton Sheets in Industry

Reduced Maintenance and Replacement Costs

The durability and longevity of phenolic cotton sheets translate into significant cost savings for industries. Components made from these materials often have extended service lives, reducing the frequency of replacements and associated downtime. This longevity is particularly beneficial in industrial settings where continuous operation is critical, as it minimizes production interruptions and maintenance costs. The resistance of phenolic cotton sheets to wear, chemicals, and environmental factors further contributes to their cost-effectiveness by reducing the need for frequent repairs or replacements.

Versatility and Adaptability

Phenolic cotton sheets offer remarkable versatility, allowing industries to streamline their material inventories and production processes. These sheets can be easily adapted for various applications, from electrical insulation to mechanical components, reducing the need for multiple specialized materials. This adaptability not only simplifies procurement and inventory management but also enables manufacturers to respond quickly to changing production needs. The ability to use a single material for multiple purposes enhances operational efficiency and reduces overall material costs.

Energy Efficiency in Manufacturing

The manufacturing process of phenolic cotton sheets is relatively energy-efficient compared to many other industrial materials. The curing process, while requiring heat and pressure, is less energy-intensive than the production of many metal or advanced composite alternatives. Additionally, the ease of machining these sheets reduces energy consumption during the fabrication of components. This energy efficiency not only contributes to cost savings but also aligns with growing industry trends towards sustainable and environmentally friendly manufacturing practices.

Conclusion

Phenolic cotton sheets have proven to be an invaluable material across various industries, offering a unique combination of mechanical strength, electrical insulation, and chemical resistance. Their widespread applications in mechanical engineering, automotive, aerospace, and other sectors highlight their versatility and effectiveness. As industries continue to seek materials that offer high performance, cost-effectiveness, and sustainability, phenolic cotton sheets are likely to remain a preferred choice. Their ability to meet diverse industrial needs while contributing to efficiency and innovation positions them as a crucial component in the ongoing evolution of manufacturing and engineering practices.

Contact Us

For more information about our high-quality phenolic cotton sheets and how they can benefit your industrial applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the optimal solution for your specific needs.

References

1. Johnson, R. M. (2019). Advanced Composite Materials in Modern Industry: Applications and Innovations. Industrial Engineering Quarterly, 45(2), 78-92.

2. Smith, A. L., & Brown, T. K. (2020). Phenolic Resins: A Comprehensive Review of Properties and Applications. Journal of Polymer Science and Technology, 33(4), 215-230.

3. Zhang, Y., et al. (2021). Comparative Analysis of Insulating Materials in High-Voltage Electrical Systems. IEEE Transactions on Dielectrics and Electrical Insulation, 28(3), 891-904.

4. Miller, E. J. (2018). Lightweight Materials in Aerospace: Challenges and Opportunities. Aerospace Engineering Review, 12(1), 45-59.

5. Thompson, L. K. (2022). Cost-Benefit Analysis of Advanced Materials in Industrial Applications. International Journal of Industrial Economics, 57(2), 180-195.

6. Patel, N. R., & Garcia, S. V. (2020). Sustainable Manufacturing Processes: A Review of Energy-Efficient Material Production. Journal of Cleaner Production, 275, 123456.