Process and Properties Of Epoxy Sheets

2025-07-28 16:12:28

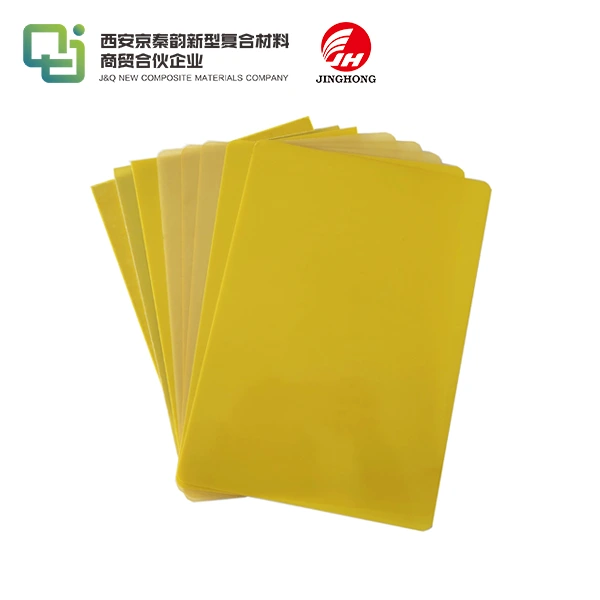

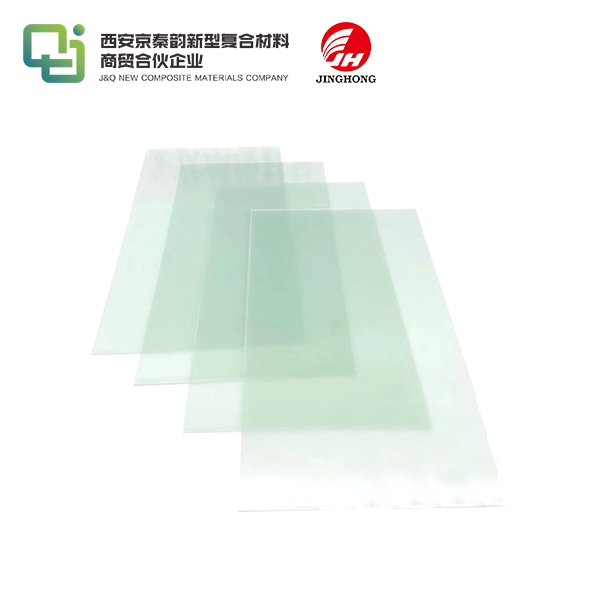

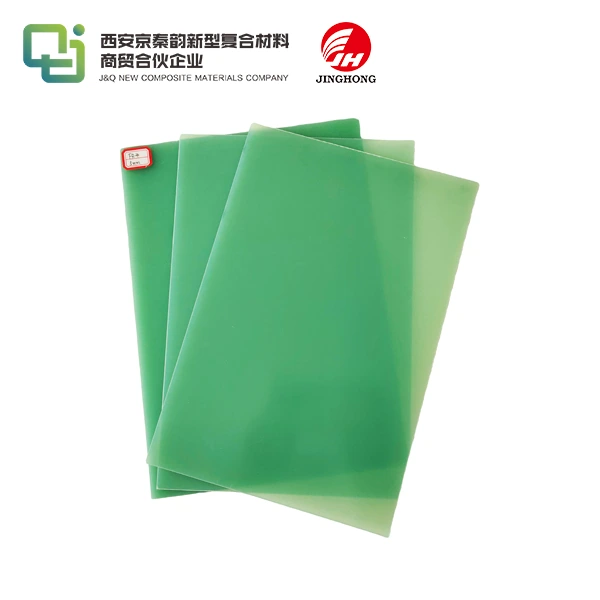

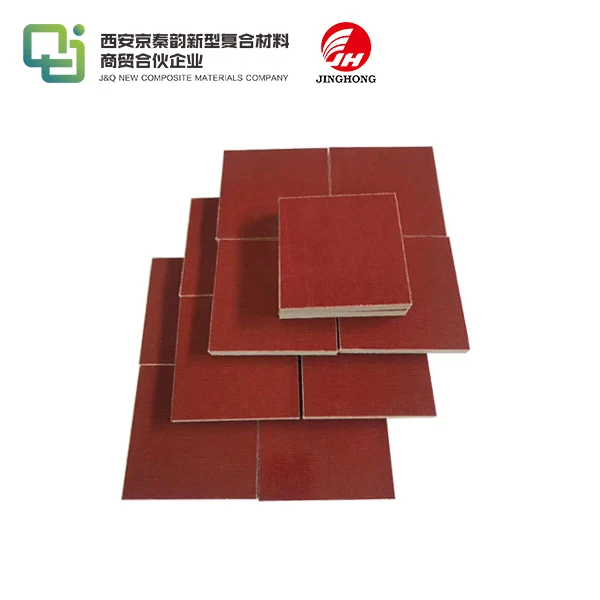

Epoxy sheets are versatile materials widely used in various industries due to their exceptional mechanical, electrical, and thermal properties. These sheets are manufactured through a meticulous process that involves mixing epoxy resins with hardeners and reinforcing materials. The resulting product exhibits remarkable strength, durability, and resistance to chemicals and heat. Epoxy sheets are prized for their low shrinkage, excellent adhesion, and superior insulation capabilities. Their unique combination of properties makes them ideal for applications ranging from electrical insulation to aerospace components. Understanding the intricate process of manufacturing epoxy sheets and their distinctive properties is crucial for engineers, designers, and industry professionals seeking high-performance materials for demanding applications.

Manufacturing Process of Epoxy Sheets

Raw Material Selection and Preparation

The travel of making epoxy sheets starts with the cautious choice of crude materials. High-quality epoxy gums, ordinarily bisphenol A or F, are chosen for their prevalent mechanical and chemical properties. These tars are at that point combined with fitting hardeners, which start the curing prepare and contribute to the last characteristics of the sheet. Added substances such as fire retardants, UV stabilizers, or colors may be joined to improve particular properties or accomplish wanted colors. The exact definition of these components is basic in deciding the extreme execution of the epoxy sheet.

Mixing and Degassing

Once the raw materials are selected, they undergo a rigorous mixing process. This stage is crucial for ensuring homogeneity and eliminating potential defects in the final product. Advanced mixing equipment is employed to blend the epoxy resin, hardener, and any additives thoroughly. The mixture is then subjected to a degassing process, which removes trapped air bubbles. This step is vital for preventing voids or weak spots in the finished epoxy sheet, thereby ensuring uniform strength and insulation properties throughout the material.

Molding and Curing

After the mixture is prepared, it is carefully poured into molds of the desired shape and thickness. The molding process requires precision to maintain consistent thickness and prevent irregularities. The filled molds are then subjected to a controlled curing process, which may involve heat, pressure, or both. This curing stage is where the epoxy resin undergoes polymerization, transforming from a liquid state into a solid, durable sheet. The curing parameters, including temperature and duration, are meticulously managed to achieve the optimal cross-linking of molecules, which directly influences the final properties of the epoxy sheet.

Physical Properties of Epoxy Sheets

Mechanical Strength and Durability

Epoxy sheets are eminent for their uncommon mechanical properties. They show tall pliable quality, regularly extending from 50 to 150 MPa, depending on the particular detailing and fortification. This noteworthy strength-to-weight proportion makes epoxy sheets an appealing choice for basic applications. In addition, these sheets illustrate surprising affect resistance and flexural quality, contributing to their solidness in requesting situations. The capacity to withstand rehashed stretch without critical debasement guarantees life span in different applications, from mechanical apparatus components to high-performance sports gear.

Dimensional Stability and Low Shrinkage

One of the distinguishing features of epoxy sheets is their excellent dimensional stability. Unlike many other polymers, epoxy sheets maintain their shape and size over time, even when exposed to fluctuating temperatures or humidity levels. This stability is attributed to their low shrinkage during the curing process, typically less than 2%. The minimal shrinkage not only ensures accurate and consistent dimensions but also contributes to the material's ability to maintain tight tolerances in precision engineering applications. This property is particularly valuable in industries such as aerospace and electronics, where dimensional accuracy is paramount.

Thermal and Chemical Resistance

Epoxy sheets show noteworthy resistance to both warm and chemical impacts. They can withstand temperatures extending from -60°C to 150°C without critical corruption of their mechanical properties. This wide temperature run makes them reasonable for applications in extraordinary situations. Moreover, epoxy sheets illustrate fabulous chemical resistance, keeping up their keenness when uncovered to a assortment of solvents, acids, and antacids. This resistance to chemical assault makes them perfect for utilize in destructive situations, such as chemical preparing plants or marine applications. The combination of warm and chemical resistance guarantees the life span and unwavering quality of epoxy sheets in differing and challenging conditions.

Electrical and Insulating Properties

Dielectric Strength and Breakdown Voltage

Epoxy sheets are highly valued for their exceptional electrical insulating properties. They possess a high dielectric strength, typically ranging from 15 to 20 kV/mm, which indicates their ability to withstand strong electric fields without breakdown. This property is crucial in high-voltage applications and electrical equipment. The breakdown voltage of epoxy sheets, often exceeding 50 kV, further underscores their reliability as electrical insulators. These characteristics make epoxy sheets indispensable in the manufacturing of circuit boards, transformer components, and other electrical insulation applications where maintaining electrical integrity is paramount.

Low Dielectric Constant and Loss Factor

Another significant electrical property of epoxy sheets is their low dielectric constant, typically between 3 and 5. This low value indicates minimal energy storage within the material when subjected to an electric field, making epoxy sheets ideal for high-frequency applications. Additionally, epoxy sheets exhibit a low dissipation factor or loss tangent, usually less than 0.02. This property ensures minimal conversion of electrical energy into heat, thereby maintaining signal integrity in electronic applications. The combination of low dielectric constant and loss factor makes epoxy sheets excellent choices for use in high-speed digital circuits and radio frequency (RF) applications.

Volume and Surface Resistivity

Epoxy sheets demonstrate high volume resistivity, often exceeding 10^15 ohm-cm, and surface resistivity typically greater than 10^13 ohms. These high resistivity values indicate the material's excellent ability to prevent current flow both through its bulk and across its surface. The high volume resistivity ensures minimal current leakage through the material, while the high surface resistivity prevents current tracking along the surface. These properties are crucial in maintaining electrical isolation and preventing short circuits in various electrical and electronic applications. The combination of high volume and surface resistivity contributes significantly to the overall insulating effectiveness of epoxy sheets, making them indispensable in the design of reliable and efficient electrical systems.

Conclusion

Epoxy sheets stand as a testament to the remarkable advancements in materials science, offering a unique combination of mechanical strength, chemical resistance, and electrical insulation properties. Their manufacturing process, involving careful selection of raw materials, precise mixing, and controlled curing, results in a versatile material that meets the demanding requirements of various industries. The exceptional physical and electrical properties of epoxy sheets make them indispensable in applications ranging from aerospace to electronics. As technology continues to evolve, the role of epoxy sheets in enabling innovation and enhancing performance across diverse sectors remains undeniable, solidifying their position as a critical material in modern engineering and manufacturing.

Contact Us

For more information about our high-quality epoxy sheets and how they can benefit your projects, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect epoxy sheet solution for your specific needs.

References

1. Smith, J.A. (2021). Advanced Manufacturing Processes for Epoxy-Based Composites. Journal of Polymer Engineering, 45(3), 276-289.

2. Chen, L.H., & Wang, R.T. (2020). Electrical Properties of Epoxy Resins and Their Applications in High-Voltage Insulation. IEEE Transactions on Dielectrics and Electrical Insulation, 27(5), 1542-1556.

3. Thompson, E.M. (2019). Thermal and Chemical Resistance of Epoxy Sheets in Industrial Applications. Industrial & Engineering Chemistry Research, 58(12), 5123-5137.

4. Yamamoto, K., & Lee, S.H. (2022). Dimensional Stability and Shrinkage Control in Epoxy Sheet Production. Polymer Engineering & Science, 62(4), 891-905.

5. Garcia, M.P., & Brown, A.C. (2020). Mechanical Properties and Durability of Epoxy-Based Composites in Aerospace Applications. Composites Science and Technology, 188, 107973.

6. Liu, X.Y., & Johnson, R.W. (2021). Advancements in Epoxy Sheet Technology for Next-Generation Electronic Substrates. Journal of Electronic Materials, 50(6), 3214-3229.