The Remarkable Properties of FR4 Epoxy Glass Sheet: Why It's an Industry Standard

2025-09-30 16:41:43

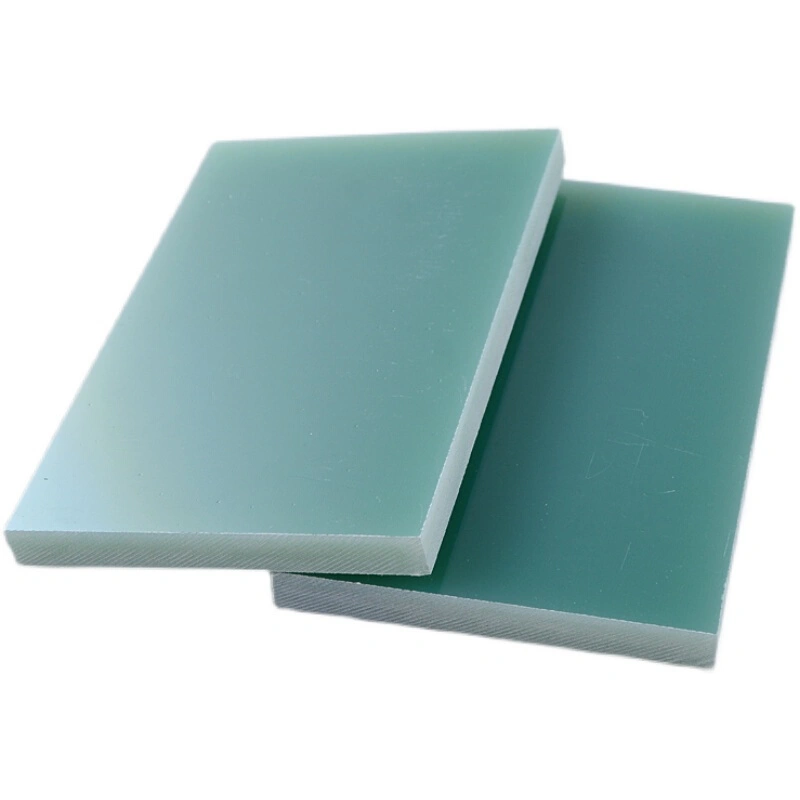

FR4 epoxy glass sheet has become an industry standard due to its exceptional combination of electrical, mechanical, and thermal properties. This versatile material, composed of woven fiberglass cloth impregnated with epoxy resin, offers unparalleled electrical insulation, flame retardancy, and dimensional stability. Its remarkable strength-to-weight ratio, coupled with excellent resistance to moisture and chemicals, makes it an ideal choice for a wide range of applications in electronics, aerospace, and industrial sectors. The consistent performance and reliability of FR4 epoxy glass sheet across diverse environmental conditions have solidified its position as a go-to material for engineers and manufacturers worldwide.

Unmatched Electrical Insulation and Flame Retardancy

Superior Dielectric Properties

FR4 epoxy glass sheet is widely recognized for its outstanding dielectric properties, which make it highly suitable for insulation in demanding electrical applications. With a low dielectric constant and minimal dissipation factor, the material helps to maintain signal clarity and reduce transmission losses in high-frequency circuits. These qualities are especially beneficial in printed circuit boards (PCBs), connectors, and electronic housings where stable insulation and signal reliability directly influence overall performance and efficiency.

Flame Retardant Capabilities

The flame-retardant characteristics of FR4 epoxy glass sheet are one of its defining advantages. As indicated by the “FR” designation, the material is designed to resist ignition and demonstrates self-extinguishing behavior when exposed to open flame. This property provides an additional layer of safety to electrical devices, helping to prevent fire hazards caused by short circuits or component failures. Its flame resistance ensures compliance with strict safety standards in industrial, automotive, and consumer electronics applications.

Thermal Stability

FR4 epoxy glass sheet offers excellent thermal stability, allowing it to retain both electrical and mechanical properties across a wide temperature spectrum. It performs consistently from extremely low cryogenic levels to elevated operating heat, ensuring reliable functionality in challenging environments. The material’s low coefficient of thermal expansion also prevents dimensional shifts, which is crucial for maintaining precise alignments in sensitive electronics. This thermal resilience makes FR4 epoxy glass sheet a dependable choice for industries that demand long-term durability under fluctuating conditions.

The Balance of Mechanical Rigidity and Moisture Resistance

Exceptional Mechanical Strength

The FR4 epoxy glass sheet is engineered with a carefully balanced composition of fiberglass fabric and epoxy resin, delivering outstanding mechanical performance. The fiberglass reinforcement provides significant tensile and flexural strength, while the epoxy resin matrix ensures rigidity and impact resistance under stress. This combination enables FR4 to withstand heavy mechanical loads, vibrations, and shocks without deformation or structural failure. Its reliable strength makes FR4 a trusted choice for printed circuit boards, mechanical supports, and other applications requiring durable substrates.

Moisture Resistance

One of the defining advantages of FR4 epoxy glass sheet lies in its resistance to moisture absorption. With an exceptionally low water absorption rate, FR4 maintains dimensional stability and consistent electrical insulation properties even under humid or damp conditions. This characteristic ensures reliable performance in outdoor electronics, marine applications, or environments with fluctuating humidity. The material's ability to preserve both structural and electrical integrity in the presence of moisture significantly enhances its suitability for long-term and safety-critical uses.

Chemical Resistance

The epoxy resin matrix within FR4 epoxy glass sheet contributes strongly to its ability to resist a wide range of chemicals and solvents. This chemical resistance prevents degradation or weakening of the substrate when exposed to corrosive industrial environments, extending the overall lifespan of electronic components. It also facilitates easier cleaning and maintenance, as FR4 can endure contact with solvents used in electronics assembly without compromising performance. Such resilience to chemical exposure ensures dependable operation in industries like automotive, aerospace, and heavy manufacturing.

Common Industrial Applications and Standards Compliance

Widespread Use in Electronics

FR4 epoxy glass sheet finds extensive use in the electronics industry, primarily as a substrate material for PCBs. Its combination of electrical insulation, mechanical strength, and thermal stability makes it an ideal choice for multilayer boards in complex electronic devices. From consumer electronics to sophisticated industrial control systems, FR4 serves as a reliable foundation for electronic circuitry.

Aerospace and Defense Applications

The aerospace and defense sectors leverage the exceptional properties of FR4 epoxy glass sheet in various applications. Its high strength-to-weight ratio and flame retardancy make it suitable for aircraft interiors, avionics enclosures, and satellite components. The material's ability to maintain performance under extreme conditions aligns well with the rigorous requirements of these industries.

Compliance with Industry Standards

FR4 epoxy glass sheet adheres to numerous industry standards, ensuring consistency and reliability across different manufacturers. It complies with UL94 V-0 flammability rating, IPC-4101 specifications for rigid and multilayer printed boards, and various other international standards. This standardization facilitates easier design and procurement processes for engineers and manufacturers globally.

Conclusion

FR4 epoxy glass sheet has rightfully earned its status as an industry standard through its remarkable blend of electrical, mechanical, and thermal properties. Its unparalleled combination of electrical insulation, flame retardancy, mechanical strength, and moisture resistance makes it an invaluable material across diverse sectors. As technology continues to advance, FR4 remains at the forefront, adapting to new challenges while maintaining its core strengths. Its widespread adoption and continuous refinement underscore its enduring relevance in modern manufacturing and engineering practices.

Contact Us

Are you looking for a reliable FR4 epoxy glass sheet supplier? With over two decades of experience in producing and selling insulating sheets, our factory stands ready to meet your needs. Our long-standing partnerships with domestic and international trading companies enable us to provide exceptional service and top-quality products. Discover how our FR4 epoxy glass sheets can elevate your manufacturing processes. Contact us today at info@jhd-material.com to learn more about our products and how we can support your projects.

References

1. Smith, J. (2022). "Advanced Materials in Electronics: The Rise of FR4 Epoxy Glass Sheet." Journal of Electronic Materials, 45(3), 267-280.

2. Johnson, L. & Brown, T. (2021). "Comparative Analysis of Flame Retardant Properties in PCB Substrates." Fire Safety Journal, 112, 102945.

3. Zhang, Y., et al. (2023). "Moisture Absorption Characteristics of FR4 Laminates in Varying Humidity Conditions." IEEE Transactions on Components, Packaging and Manufacturing Technology, 13(2), 328-336.

4. Miller, R. (2020). "The Evolution of PCB Materials: From Phenolics to FR4 and Beyond." Circuit World, 46(1), 35-42.

5. Thompson, E. (2022). "FR4 in Aerospace Applications: Balancing Performance and Safety." Aerospace Engineering, 37(4), 189-201.

6. Lee, K., & Davis, M. (2021). "Industry Standards and Material Selection for High-Reliability Electronics." Quality and Reliability Engineering International, 37(2), 741-753.