What are the Common Insulating Materials for Explosion-Proof Electrical Equipment?

2021-05-31

According to the different material states, the insulating materials of explosion-proof electrical can be divided into solid insulating materials and liquid insulating materials. This classification is only applicable to explosion-proof electrical appliances.

Solid insulating material

solid insulating material is an insulating material whose material is in a solid state in actual use. Some materials are liquid when supplied and become solid after use. They are also considered as solid insulating materials.

The following table lists the types of solid insulation materials commonly used in explosion-proof electrical equipment

Material grade | Comparative Tracking Index (CTI) | Material name |

I | 600≤CTI | Ceramics (glazed), mica, glass |

II | 400≤CTI<600 | Melamine asbestos arc plastic, silicon organic asbestos arc resistant plastic, unsaturated polyester aggregate |

III-a | 175≤CTI<400 | Polytetrafluoroethylene plastic, melamine glass fiber plastic, epoxy glass cloth board treated with arc-resistant paint |

III-b | 100≤CTI<175 | Phenolic plastic |

According to the grades of solid insulating materials commonly used in explosion-proof electrical equipment listed in the table, they are evaluated according to their comparative tracking index (CTI). Although this grade is only the electrical performance on the surface, its mechanical properties, heat resistance, and chemical resistance are different. Therefore, when people choose this material, they should also consider its mechanical properties, heat resistance, and chemical resistance according to the specific conditions of its use environment.

Ceramic (glazed) material

It is an inorganic non-metal insulating material, which is formed by sintering of metal oxides and oxygen-free metal compounds. Its hardness is between 1000-5000HV; tensile strength is between 26-36MPa; compressive strength is between 460-680MPa; melting point is above 2000℃; thermal expansion coefficient is small; high chemical stability, corrosion resistance, etc.

Plastic insulation material

Melamine formaldehyde resin (MF)

It is a thermosetting plastic with melamine formaldehyde resin as the main raw material, cellulose as auxiliary material, and various additives. It has good arc resistance and self-extinguishing after ignition, but has low impact resistance and poor dimensional stability. It is suitable for manufacturing insulating parts of electrical equipment.

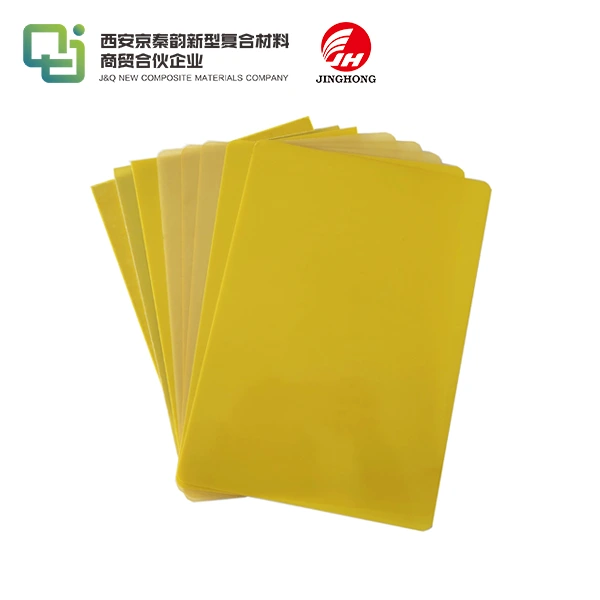

Epoxy resin (EP)

It is a composite thermosetting plastic with epoxy resin as the main material and other additives as auxiliary materials. This material such as FR4 sheet and 3240 epoxy board has good insulation performance, good mechanical performance, good bonding performance, resistance to sea water (salt water), and small shrinkage. It is suitable for making electrical insulation parts and printed circuit boards.

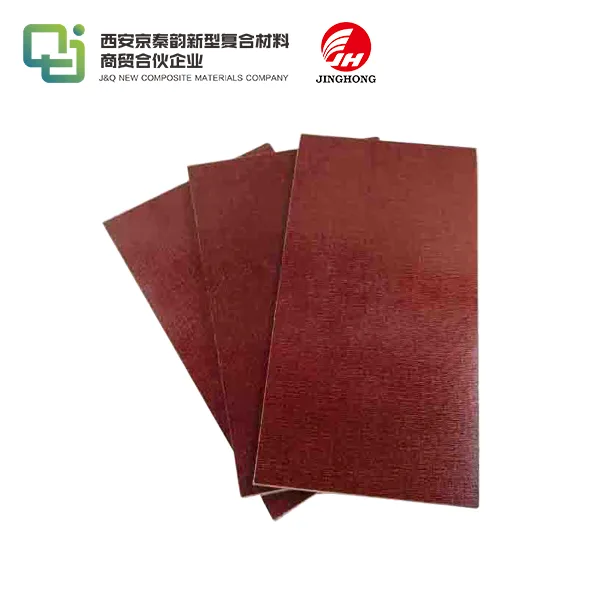

Phenolic Plastic (PF)

It is a thermosetting plastic, with phenol resin as the main raw material, and other additives as auxiliary materials. For example, when the material is glass fiber, the product is called phenolic glass fiber reinforced plastic, which has high strength, high temperature resistance and corrosion resistance; when the material is wood flour, the product is called bakelite, such as 3026 Phenolic Cotton Cloth Laminated Sheet and phenolic paper board, which has good mechanical properties and insulation properties.

Acrylonitrile-butadiene-styrene copolymer (ABS)

It is an excellent thermoplastic engineering plastic. Because of its good mechanical properties, insulation properties, heat resistance, corrosion resistance, as well as good material impact resistance and dimensional stability of molded parts, it is widely used in the manufacture of structural parts and insulation parts for various equipment, such as special explosion-proof parts such as the battery slot of the battery (Exs-U).

Polyethylene (PE)

This thermoplastic is polymerized by ethylene and is usually divided into low density polyethylene (LDPE) and high density polyethylene (HDPE).

Low-density polyethylene (LDPE) has good softness, ductility and transparency, and is suitable for the manufacture of various types of plastic films, such as between the positive and negative electrodes of the battery; high-density polyethylene (HDPE) has better Its mechanical properties and wide operating temperature range are suitable for the manufacture of various types of pipes, such as small electrical enclosures, special explosion-proof storage batteries (Exs-U) battery slots, etc.

Whether it is LDPE or HDPE, they all have good electrical insulation properties and have been well used in the manufacture of explosion-proof electrical equipment.