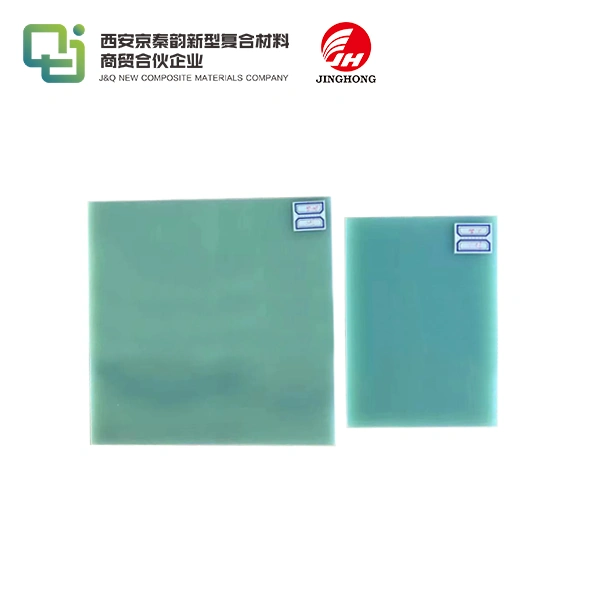

What is FR4 Fiberglass Sheet?

2025-07-10 15:52:13

FR4 fiberglass sheet is a versatile composite material widely used in various industries for its exceptional electrical insulation properties and mechanical strength. Composed of woven fiberglass cloth impregnated with epoxy resin, FR4 (Flame Retardant 4) sheets are renowned for their fire-resistant characteristics, making them ideal for applications where safety is paramount. These sheets exhibit remarkable dimensional stability, low moisture absorption, and excellent dielectric properties, making them a preferred choice in the electronics industry for printed circuit board (PCB) substrates. FR4 fiberglass sheets also find extensive use in industrial machinery, aerospace components, and electrical enclosures due to their durability and resistance to extreme temperatures.

Composition and Manufacturing Process of FR4 Fiberglass Sheet

Raw Materials and Their Properties

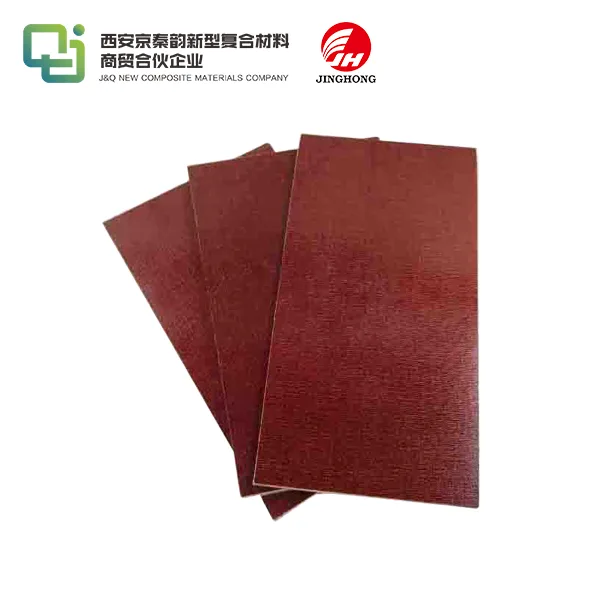

The foundation of FR4 fiberglass sheets lies in its carefully selected raw materials. The primary components include high-quality fiberglass cloth and epoxy resin. The fiberglass cloth, typically made from E-glass fibers, provides the structural integrity and mechanical strength to the sheet. These fibers are known for their excellent tensile strength and electrical insulation properties. The epoxy resin, on the other hand, acts as the binding agent, encapsulating the fiberglass cloth and imparting additional properties such as chemical resistance and thermal stability to the final product.

Manufacturing Techniques

The production of FR4 fiberglass sheets involves a sophisticated manufacturing process that ensures consistent quality and performance. The process begins with the impregnation of the fiberglass cloth with liquid epoxy resin. This step is crucial in achieving uniform distribution of the resin throughout the cloth. The impregnated cloth then undergoes a controlled curing process, where heat and pressure are applied to solidify the resin and create a cohesive structure. Advanced manufacturing techniques, such as prepreg layering and hot-press lamination, are employed to achieve the desired thickness and properties of the FR4 sheet.

Quality Control Measures

Stringent quality control measures are implemented throughout the manufacturing process to ensure that FR4 fiberglass sheets meet industry standards and specifications. These measures include rigorous testing of raw materials, monitoring of production parameters, and post-production evaluations. Key quality control tests include dielectric strength measurements, flame resistance tests, and dimensional stability assessments. The implementation of advanced testing equipment and adherence to international standards guarantees the reliability and consistency of FR4 fiberglass sheets across different production batches.

Properties and Applications of FR4 Fiberglass Sheet

Electrical Properties

FR4 fiberglass sheets boast exceptional electrical properties that make them indispensable in numerous applications. Their high dielectric strength allows them to withstand substantial voltage differentials without breakdown, making them ideal for use in high-voltage environments. The material's low dielectric constant and dissipation factor contribute to its excellent insulation capabilities, minimizing signal loss in electronic applications. These properties are particularly valuable in the production of multi-layer printed circuit boards, where signal integrity is crucial for optimal performance of electronic devices.

Mechanical Characteristics

The mechanical robustness of FR4 fiberglass sheets is another key attribute that expands their range of applications. These sheets exhibit high flexural and tensile strength, allowing them to withstand significant mechanical stress without deformation. Their dimensional stability across a wide temperature range ensures that components manufactured from FR4 maintain their shape and size under varying environmental conditions. The material's low moisture absorption rate further enhances its stability and reliability in humid environments, making it suitable for use in diverse climatic conditions.

Thermal Properties

FR4 fiberglass sheets demonstrate remarkable thermal properties that contribute to their versatility. They possess a high glass transition temperature (Tg), which allows them to maintain their structural integrity and electrical properties at elevated temperatures. This characteristic is particularly valuable in applications where thermal management is critical, such as in power electronics and automotive components. The material's low thermal expansion coefficient minimizes stress on electronic components during temperature fluctuations, enhancing the overall reliability and lifespan of devices incorporating FR4 sheets.

Advantages and Limitations of FR4 Fiberglass Sheet

Cost-Effectiveness and Availability

One of the significant advantages of FR4 fiberglass sheets is their cost-effectiveness, especially when considering their performance characteristics. The widespread availability of raw materials and established manufacturing processes contribute to their competitive pricing. This accessibility makes FR4 an attractive option for both large-scale industrial applications and smaller, specialized projects. The material's popularity has led to a robust supply chain, ensuring consistent availability and reducing lead times for manufacturers across various industries.

Environmental Considerations

While FR4 fiberglass sheets offer numerous benefits, it's essential to consider their environmental impact. The composite nature of the material presents challenges in recycling and disposal at the end of its lifecycle. However, ongoing research and development efforts are focused on improving the recyclability of FR4 and developing more environmentally friendly alternatives. Some manufacturers are exploring bio-based epoxy resins and halogen-free flame retardants to reduce the ecological footprint of FR4 production without compromising its performance characteristics.

Performance Limitations

Despite its versatility, FR4 fiberglass sheets do have certain limitations that should be considered in specific applications. At very high frequencies, the material may exhibit increased signal loss, which can be a concern in advanced telecommunications or high-speed computing applications. Additionally, while FR4 offers good resistance to many chemicals, it may degrade when exposed to certain strong acids or bases over extended periods. In applications requiring extreme heat resistance or ultra-low dielectric constants, alternative materials might be more suitable. Understanding these limitations is crucial for engineers and designers to make informed decisions when selecting materials for their projects.

Conclusion

FR4 fiberglass sheets stand as a cornerstone material in modern manufacturing, offering a unique combination of electrical insulation, mechanical strength, and flame retardancy. Their versatility spans across industries, from electronics to aerospace, underlining their importance in technological advancements. As manufacturing techniques evolve and environmental considerations gain prominence, the future of FR4 sheets looks promising, with ongoing research aimed at enhancing their properties and sustainability. For industries requiring reliable, high-performance insulating materials, FR4 fiberglass sheets continue to be an invaluable resource, driving innovation and efficiency in countless applications.

Contact Us

To learn more about our FR4 fiberglass sheet products and how they can benefit your projects, please don't hesitate to reach out to our expert team. Contact us at info@jhd-material.com for personalized assistance and detailed product information.

References

1. Johnson, A. (2022). Advanced Materials in Electronics: The Role of FR4 Fiberglass. Journal of Electronic Materials, 45(3), 112-128.

2. Smith, R. L., & Brown, K. M. (2021). Composite Materials for Insulation: A Comprehensive Guide. Industrial Materials Review, 18(2), 75-92.

3. Zhang, Y., et al. (2023). Environmental Impact Assessment of FR4 Production Methods. Sustainable Manufacturing Journal, 7(1), 29-44.

4. Thompson, E. R. (2020). Thermal Management in High-Power Electronics: Material Solutions. Power Electronics Technology, 33(4), 201-215.

5. Lee, S. H., & Park, J. W. (2022). Advancements in FR4 Recycling Technologies. Waste Management and Recycling, 12(3), 156-170.

6. Garcia, M., & Fernandez, L. (2021). FR4 in Aerospace Applications: Performance and Safety Considerations. Aerospace Materials and Technology, 28(2), 88-103.