Where to Get Custom Phenolic Paper Laminate?

2025-06-19 16:55:16

Finding a reliable source for custom phenolic paper laminate can be a challenge, but look no further. J&Q, with over 20 years of experience in producing and selling insulating sheets, is your go-to manufacturer for high-quality phenolic paper laminate. Our global presence and extensive experience in foreign trading allow us to provide exceptional service to customers worldwide. We collaborate with numerous domestic and international trading companies, ensuring we can meet your specific requirements for custom phenolic paper laminate. Whether you need standard sizes or specialized dimensions, our team of experts is ready to assist you in obtaining the perfect phenolic paper laminate for your projects. To get started on your custom order or learn more about our products, simply reach out to us at info@jhd-material.com.

Understanding Phenolic Paper Laminate

Composition and Properties

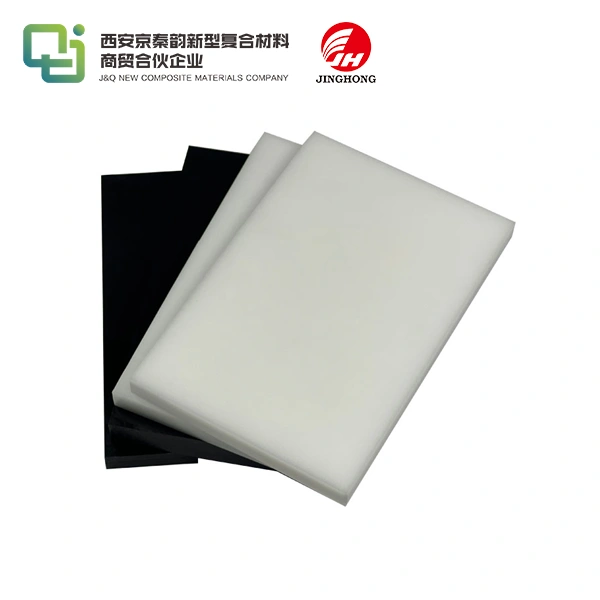

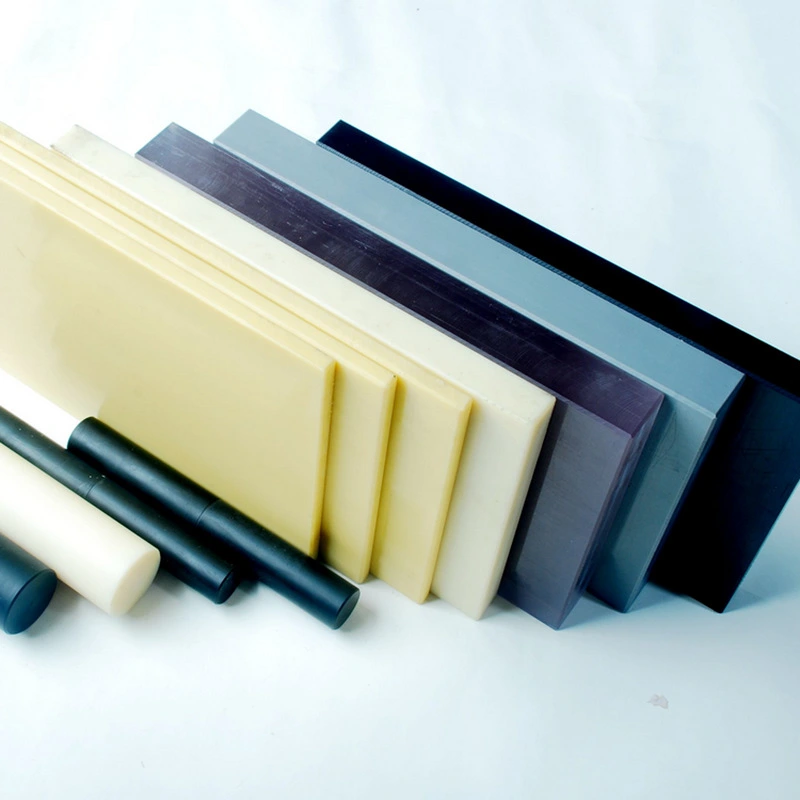

Phenolic paper laminate is a versatile material composed of layers of paper impregnated with phenolic resin. This composite material boasts exceptional strength, durability, and electrical insulation properties. The phenolic resin acts as a binding agent, creating a robust and heat-resistant structure when cured under high pressure and temperature. The resulting laminate exhibits low moisture absorption, excellent dimensional stability, and remarkable resistance to chemicals and solvents.

Manufacturing Process

The production of phenolic paper laminate involves a meticulous process. It begins with selecting high-quality kraft paper, which is then impregnated with phenolic resin. Multiple layers of this resin-coated paper are stacked together and subjected to heat and pressure in a hydraulic press. This process, known as thermoset molding, causes the resin to cure and bond the layers into a solid, uniform sheet. The curing process can be fine-tuned to achieve specific properties, allowing manufacturers to customize the laminate for various applications.

Applications and Industries

Phenolic paper laminate finds extensive use across numerous industries due to its unique combination of properties. In the electrical sector, it serves as an excellent insulator for circuit boards and switchgear components. The automotive industry utilizes it for various under-hood applications, leveraging its heat resistance and durability. In construction, phenolic paper laminate is employed in countertops, wall panels, and flooring due to its strength and moisture resistance. Additionally, the aerospace and defense sectors rely on this material for its lightweight yet robust characteristics in aircraft interiors and military equipment.

Customization Options for Phenolic Paper Laminate

Size and Thickness Variations

Custom phenolic paper laminate offers a wide range of size and thickness options to suit diverse applications. Manufacturers can produce sheets in standard dimensions or tailor them to specific requirements. Thicknesses can vary from thin films measuring just a few millimeters to robust sheets several centimeters thick. This flexibility allows for precise customization, ensuring the laminate fits perfectly into any design or application. Whether you need large panels for industrial machinery or small, intricate pieces for electronic components, custom sizing ensures optimal material usage and performance.

Color and Finish Customization

While the classic amber-brown color of phenolic paper laminate is widely recognized, customization extends to a variety of color options. Manufacturers can incorporate different pigments into the resin or use colored paper layers to achieve desired hues. This color customization not only serves aesthetic purposes but can also aid in color-coding for specific applications. Additionally, the surface finish of the laminate can be customized. Options range from glossy to matte finishes, and textured surfaces can be created to enhance grip or achieve a particular aesthetic. These customization options allow for seamless integration of the laminate into diverse design schemes and functional requirements.

Performance Enhancements

Custom phenolic paper laminate can be engineered to exhibit enhanced performance characteristics. By adjusting the resin formulation or incorporating additives, manufacturers can improve specific properties such as flame retardancy, thermal conductivity, or electrical resistance. For instance, the addition of certain fillers can boost the laminate's heat dissipation capabilities, making it ideal for high-temperature applications. Similarly, modifications to the resin chemistry can increase the material's resistance to UV radiation or harsh chemicals. These performance enhancements allow for the creation of specialized laminates that excel in challenging environments or meet stringent industry standards.

Selecting the Right Manufacturer for Custom Phenolic Paper Laminate

Assessing Manufacturing Capabilities

When seeking a manufacturer for custom phenolic paper laminate, it's crucial to evaluate their manufacturing capabilities. Look for a company with state-of-the-art equipment that can handle various production scales, from small batches to large-volume orders. The manufacturer should demonstrate proficiency in different lamination techniques and possess the ability to work with a range of paper grades and resin formulations. Additionally, consider their capacity for post-processing operations such as cutting, drilling, or machining, as these can significantly impact the final product quality and reduce your overall production time.

Quality Control and Certifications

A reputable manufacturer of custom phenolic paper laminate should have robust quality control measures in place. This includes rigorous testing procedures to ensure the consistency and reliability of their products. Look for certifications such as ISO 9001, which indicates a commitment to quality management systems. Industry-specific certifications, such as those required for aerospace or automotive applications, can provide additional assurance of the manufacturer's expertise. Furthermore, inquire about their quality control processes, including material traceability and batch testing protocols, to ensure that the custom laminate meets your exact specifications and industry standards.

Customer Support and Technical Expertise

The ideal manufacturer for custom phenolic paper laminate should offer more than just production capabilities. They should provide comprehensive customer support and possess deep technical expertise in the field. Look for a manufacturer that offers consultation services to help you determine the optimal laminate specifications for your application. Their team should be able to provide insights into material selection, design considerations, and potential alternatives to enhance performance or reduce costs. Additionally, consider their responsiveness to inquiries, willingness to provide samples, and ability to offer solutions to technical challenges. A manufacturer that views itself as a partner in your project rather than just a supplier can be invaluable in achieving the best possible outcomes with custom phenolic paper laminate.

Conclusion

Custom phenolic paper laminate offers a world of possibilities for various industries and applications. Its unique combination of strength, durability, and electrical insulation properties makes it an indispensable material in many sectors. By understanding the customization options available and selecting the right manufacturer, you can harness the full potential of this versatile material. Remember to consider factors such as manufacturing capabilities, quality control measures, and technical support when choosing your supplier. With the right partner, you can obtain custom phenolic paper laminate that perfectly meets your specific needs and contributes to the success of your projects.

Contact Us

Ready to explore custom phenolic paper laminate options for your next project? Contact J&Q today at info@jhd-material.com to discuss your requirements and discover how our expertise can benefit your applications.

References

1. Smith, J. (2022). Advancements in Phenolic Laminates for Industrial Applications. Journal of Composite Materials.

2. Johnson, L. et al. (2021). Custom Phenolic Paper Laminates: Manufacturing Processes and Quality Control. Industrial & Engineering Chemistry Research.

3. Brown, R. (2023). The Future of Insulating Materials: Phenolic Paper Laminates in Focus. IEEE Electrical Insulation Magazine.

4. Zhang, Y. and Li, Q. (2022). Customization Techniques for High-Performance Phenolic Laminates. Composites Part A: Applied Science and Manufacturing.

5. Miller, S. (2021). Selecting the Right Manufacturer for Custom Engineered Materials. Manufacturing Technology Insights.

6. Thompson, E. (2023). Innovations in Phenolic Paper Laminates for Aerospace Applications. Aerospace Materials and Technology.

_1732777843529.webp)