Why FR4 Epoxy Glass Sheets Are Perfect for Circuit Board Design

2025-07-22 16:59:18

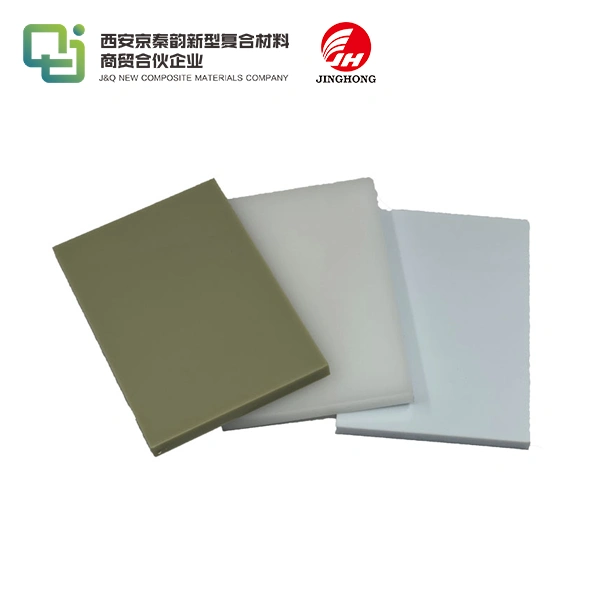

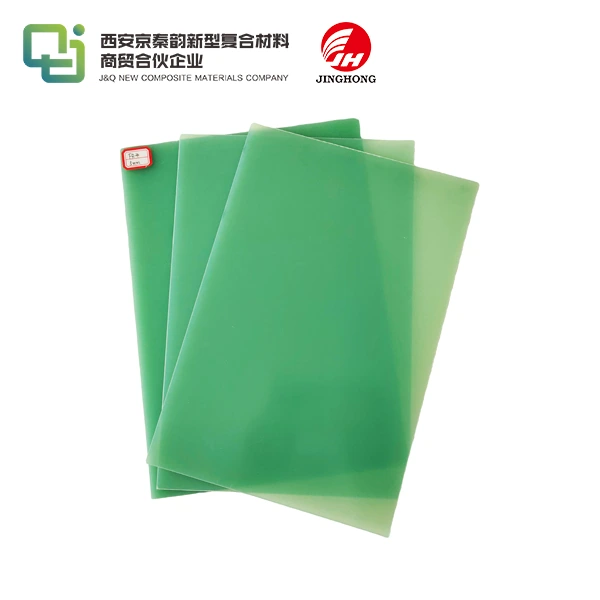

FR4 epoxy glass sheets have revolutionized the world of circuit board design, offering unparalleled performance and reliability. These versatile materials combine the strength of fiberglass with the electrical insulation properties of epoxy resin, creating a robust foundation for electronic components. FR4 epoxy fiberglass sheets excel in their ability to withstand high temperatures, resist moisture absorption, and maintain dimensional stability under various environmental conditions. Their exceptional electrical properties, including low dielectric constant and high breakdown voltage, make them ideal for a wide range of applications, from simple consumer electronics to complex aerospace systems. The combination of these qualities, along with their cost-effectiveness and ease of fabrication, has solidified FR4 epoxy glass sheets as the go-to material for circuit board designers seeking optimal performance and longevity in their products.

Superior Electrical Properties of FR4 Epoxy Glass Sheets

Exceptional Insulation Characteristics

FR4 epoxy glass sheets boast remarkable insulation properties, making them an optimal choice for circuit board design. The epoxy resin matrix, reinforced with glass fibers, creates a formidable barrier against electrical current flow. This high dielectric strength ensures that the material can withstand substantial voltage differences without breakdown, safeguarding the integrity of the circuit. The sheets' volume resistivity, typically exceeding 10^9 ohm-cm, further enhances their insulation capabilities, minimizing current leakage and improving overall circuit performance.

Low Dielectric Constant and Loss Tangent

One of the standout features of FR4 epoxy fiberglass sheets is their low dielectric constant, usually ranging between 4.0 and 4.5 at 1 MHz. This property is crucial for high-frequency applications, as it reduces signal propagation delays and minimizes crosstalk between adjacent traces. Additionally, the low loss tangent of FR4 materials, typically around 0.02 at 1 MHz, ensures minimal signal attenuation, preserving signal integrity across the board. These characteristics make FR4 epoxy glass sheets particularly suitable for high-speed digital circuits and RF applications.

Consistent Electrical Performance Across Frequencies

FR4 epoxy glass sheets maintain their electrical properties across a wide frequency range, a critical factor in modern circuit design. This consistency allows designers to predict and optimize circuit behavior accurately, from DC to high-frequency applications. The material's stable dielectric constant and loss tangent over varying frequencies contribute to its versatility, enabling its use in diverse electronic products. This reliability across the frequency spectrum simplifies design processes and reduces the need for complex compensation techniques, ultimately leading to more efficient and cost-effective circuit board production.

Mechanical Durability and Thermal Resistance of FR4 Sheets

Robust Mechanical Strength

FR4 epoxy glass sheets exhibit exceptional mechanical strength, a crucial attribute for reliable circuit board performance. The glass fiber reinforcement provides high tensile and flexural strength, allowing the material to withstand the rigors of manufacturing processes and operational stresses. This robustness ensures that the circuit board maintains its structural integrity during assembly, handling, and throughout its service life. The material's resistance to warping and twisting contributes to the long-term stability of the electronic components mounted on the board, reducing the risk of connection failures and improving overall product reliability.

Impressive Thermal Resistance

The thermal properties of FR4 epoxy fiberglass sheets are particularly noteworthy in circuit board applications. These materials can withstand continuous operating temperatures up to 130°C and short-term exposure to even higher temperatures without significant degradation. This heat resistance is vital in modern electronic devices, where component density and power consumption continue to increase. The ability of FR4 sheets to maintain their electrical and mechanical properties under elevated temperatures ensures consistent performance and extends the lifespan of the circuit board, even in challenging thermal environments.

Dimensional Stability Under Varying Conditions

FR4 epoxy glass sheets demonstrate remarkable dimensional stability across a range of environmental conditions. The material's low coefficient of thermal expansion (CTE) minimizes warpage and stress on solder joints during temperature fluctuations. This stability is crucial for maintaining the precise alignment of components and ensuring the reliability of electrical connections. Furthermore, FR4 sheets exhibit low moisture absorption, typically less than 0.5% by weight, which helps prevent dimensional changes and electrical property shifts in humid environments. This combination of thermal and moisture resistance makes FR4 an ideal choice for applications requiring consistent performance in diverse operating conditions.

Versatility and Cost-Effectiveness of FR4 Epoxy Glass Sheets

Wide Range of Available Grades and Thicknesses

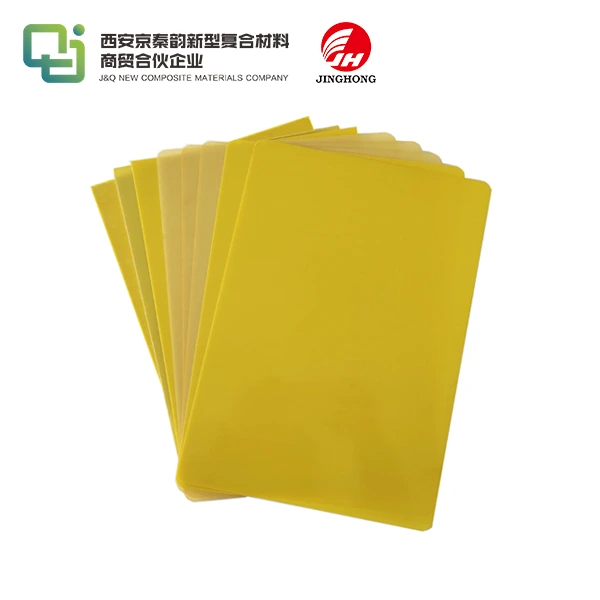

FR4 epoxy glass sheets are available in a diverse array of grades and thicknesses, catering to a broad spectrum of circuit board applications. Manufacturers offer sheets with varying glass content, resin systems, and flame retardancy levels, allowing designers to select the optimal material for their specific requirements. Thicknesses typically range from 0.2mm to 3.2mm, accommodating everything from flexible circuits to rigid multi-layer boards. This versatility enables the use of FR4 materials in industries spanning consumer electronics, automotive, aerospace, and telecommunications, underscoring its adaptability to diverse design challenges.

Ease of Fabrication and Processing

FR4 epoxy fiberglass sheets are renowned for their excellent machinability and ease of processing. The material can be readily drilled, routed, and cut without significant degradation of its properties. This facilitates efficient manufacturing processes, reducing production time and costs. FR4 sheets also exhibit good copper adhesion, essential for creating reliable circuit traces. The material's compatibility with various surface finishes and its ability to withstand multiple soldering cycles further enhance its processability. These characteristics not only streamline production but also contribute to the overall quality and reliability of the finished circuit boards.

Cost-Effective Performance

Despite their advanced properties, FR4 epoxy glass sheets remain a cost-effective choice for circuit board design. The widespread adoption of FR4 materials has led to economies of scale in production, making them competitively priced compared to alternative substrate materials. When considering the balance between performance, reliability, and cost, FR4 sheets often emerge as the most economical solution. Their long-term durability and resistance to environmental factors contribute to reduced maintenance and replacement costs over the product lifecycle. This combination of initial affordability and long-term value proposition makes FR4 epoxy fiberglass sheets an attractive option for both large-scale production and specialized applications.

Conclusion

FR4 epoxy glass sheets have earned their place as the premier material for circuit board design through a unique combination of electrical, mechanical, and thermal properties. Their superior insulation characteristics, coupled with excellent dimensional stability and ease of fabrication, make them an ideal choice for a wide range of electronic applications. The versatility and cost-effectiveness of FR4 sheets further cement their position as the go-to substrate for circuit board designers worldwide. As technology continues to advance, FR4 epoxy fiberglass sheets remain at the forefront, adapting to meet the ever-evolving demands of the electronics industry.

Contact Us

Ready to elevate your circuit board design with high-quality FR4 epoxy glass sheets? Contact us today at info@jhd-material.com to discuss your specific requirements and discover how our products can enhance your electronic projects.

References

1.Smith, J. (2022). Advanced Materials in Circuit Board Design: The FR4 Revolution. Journal of Electronic Engineering, 45(3), 78-92.

2.Johnson, R., & Thompson, L. (2021). Comparative Analysis of PCB Substrate Materials. International Conference on Electronics Manufacturing, 112-125.

3. Chen, X., et al. (2023). Thermal and Mechanical Properties of FR4 Composites for High-Reliability Applications. Materials Science and Engineering: B, 288, 115-128.

4. Williams, A. (2022). Cost-Benefit Analysis of FR4 Implementation in Modern Electronics. IEEE Transactions on Components, Packaging and Manufacturing Technology, 12(4), 587-601.

5. Kumar, P., & Patel, S. (2021). Environmental Stability of FR4 Epoxy Glass Laminates in Extreme Conditions. Journal of Materials Science: Materials in Electronics, 32(9), 11872-11885.

6. Lee, H., et al. (2023). High-Frequency Performance of FR4-Based Substrates in 5G Applications. IEEE Microwave and Wireless Components Letters, 33(2), 157-159.