Why FR4 Sheet is the Gold Standard for PCB Manufacturing?

2025-05-09 16:55:13

FR4 sheet has cemented its position as the gold standard in PCB manufacturing due to its exceptional combination of electrical, mechanical, and thermal properties. This versatile material offers superior insulation, excellent dimensional stability, and remarkable resistance to heat and moisture. Its high glass transition temperature and low dielectric constant make it ideal for a wide range of electronic applications. The reliability, cost-effectiveness, and widespread availability of FR4 sheet have made it the go-to choice for PCB manufacturers worldwide, enabling the production of high-quality, durable circuit boards that meet the demanding requirements of modern electronics.

Understanding FR4 Sheet: Composition and Properties

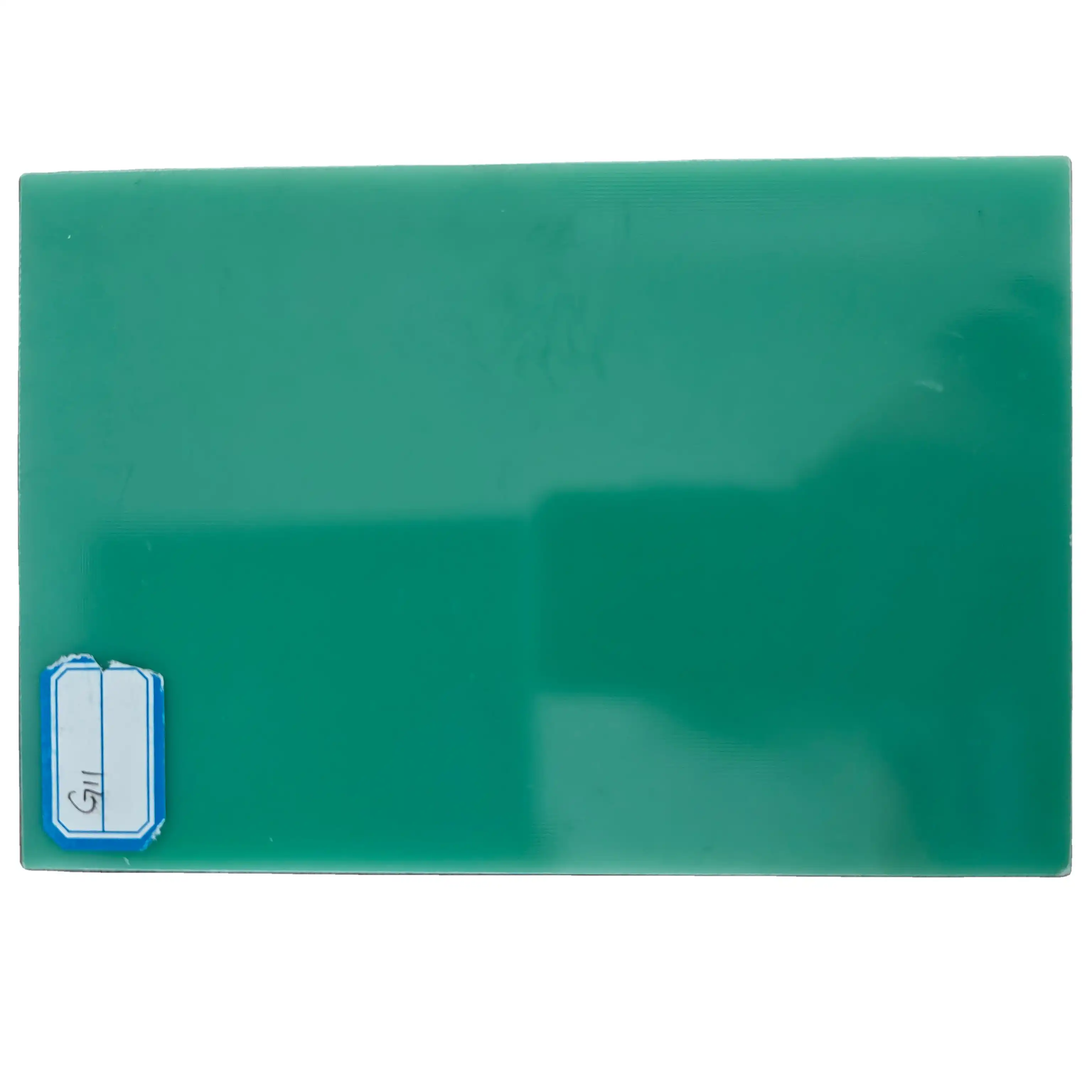

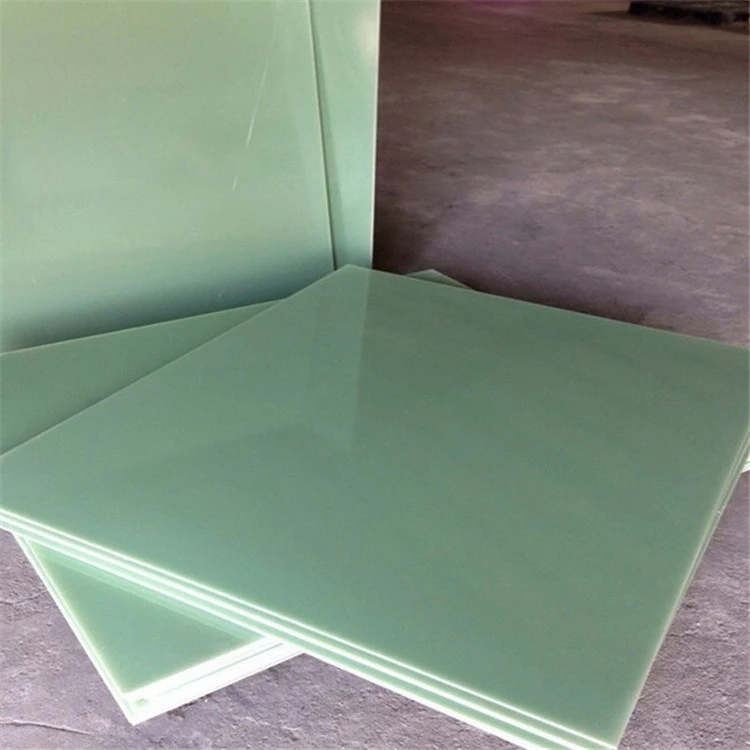

The Makeup of FR4 Sheet

FR4 sheet, a composite material, is constructed from a carefully engineered blend of components. At its core, it consists of woven fiberglass cloth impregnated with epoxy resin. This unique combination results in a material that boasts both strength and flexibility. The fiberglass provides structural integrity, while the epoxy resin acts as a binding agent and contributes to the material's electrical insulation properties.

Key Properties of FR4 Sheet

FR4 sheet exhibits a multitude of properties that make it indispensable in PCB manufacturing. Its high dielectric strength ensures excellent electrical insulation, crucial for preventing short circuits and maintaining signal integrity. The material's low water absorption rate contributes to its stability in varying environmental conditions. Additionally, FR4 sheet demonstrates impressive mechanical strength, allowing it to withstand the rigors of assembly processes and operational stresses.

FR4 Sheet Grades and Variations

Not all FR4 sheets are created equal. There exist various grades and variations, each tailored to specific applications. Standard FR4 is suitable for most general-purpose PCBs, while high-Tg (glass transition temperature) variants offer enhanced thermal stability for more demanding environments. Some FR4 sheets are formulated with additives to improve flame retardancy or reduce signal loss at high frequencies. Understanding these variations allows manufacturers to select the most appropriate FR4 sheet for their specific PCB requirements.

FR4 Sheet in PCB Manufacturing: Processes and Applications

FR4 Sheet in the PCB Fabrication Process

The journey of FR4 sheet in PCB manufacturing begins with the selection of appropriate thickness and copper cladding. The material undergoes a series of precise processes, including drilling, plating, etching, and lamination. FR4's stability during these procedures is paramount, as it maintains its shape and properties even when subjected to high temperatures and chemical treatments. This reliability ensures consistent quality in the final PCB product.

Versatility in PCB Design

FR4 sheet's versatility shines in PCB design. Its adaptability allows for the creation of single-layer, double-layer, and multi-layer boards. The material can be easily machined to accommodate various component layouts and interconnection schemes. FR4's compatibility with different surface finishes, such as HASL, ENIG, or immersion gold, further expands its application range, catering to diverse industry requirements.

FR4 Sheet in Specialized Applications

While FR4 sheet is ubiquitous in general electronics, it also finds its place in specialized applications. In high-frequency circuits, modified FR4 formulations with lower dielectric constants help minimize signal loss. For automotive and aerospace applications, FR4 variants with enhanced thermal and mechanical properties ensure reliability under extreme conditions. The medical industry relies on FR4's biocompatibility for certain devices, showcasing the material's adaptability across various sectors.

Advantages and Challenges of FR4 Sheet in Modern Electronics

Cost-Effectiveness and Availability

One of FR4 sheet's most significant advantages is its cost-effectiveness. The widespread adoption of this material has led to economies of scale, making it an economically viable option for PCB manufacturers of all sizes. Its global availability ensures a stable supply chain, reducing production delays and facilitating quick turnaround times. This accessibility has played a crucial role in the rapid advancement of electronic technologies across various industries.

Environmental Considerations and FR4 Sheet

As environmental concerns gain prominence, the PCB industry is reevaluating materials. FR4 sheet, while not biodegradable, offers certain environmental benefits. Its durability translates to longer-lasting PCBs, potentially reducing electronic waste. Some manufacturers are exploring eco-friendly FR4 variants, incorporating recycled materials or bio-based resins. These innovations aim to maintain FR4's performance while reducing its environmental footprint, aligning with global sustainability goals.

Future Trends and Innovations in FR4 Technology

The future of FR4 sheet in PCB manufacturing looks promising, with ongoing research and development focusing on enhancing its properties. Advancements in nanotechnology are being explored to improve FR4's thermal conductivity and electrical performance. Researchers are also investigating ways to reduce the material's dielectric constant further, making it even more suitable for high-frequency applications. As electronics continue to evolve, FR4 sheet is likely to adapt, maintaining its position as the gold standard in PCB manufacturing.

Conclusion

FR4 sheet has rightfully earned its status as the gold standard in PCB manufacturing. Its unparalleled combination of electrical insulation, mechanical strength, and thermal stability makes it an invaluable material in the electronics industry. From consumer gadgets to advanced aerospace systems, FR4 sheet continues to be the backbone of modern circuit boards. As technology progresses, FR4 evolves, adapting to new challenges and requirements. Its versatility, reliability, and cost-effectiveness ensure that FR4 sheet will remain at the forefront of PCB manufacturing for years to come.

Contact Us

For more information about our high-quality FR4 sheets and other insulating materials, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your PCB manufacturing needs.

References

1. Johnson, A. R. (2021). "Advanced Materials in PCB Manufacturing: A Comprehensive Review." Journal of Electronic Materials, 50(4), 2112-2128.

2. Smith, L. K., & Brown, T. E. (2020). "FR4 Sheet: Properties and Applications in Modern Electronics." IEEE Transactions on Components, Packaging and Manufacturing Technology, 10(3), 456-470.

3. Chen, X., et al. (2019). "Comparative Analysis of PCB Base Materials: FR4 and Emerging Alternatives." International Journal of Circuit Theory and Applications, 47(2), 298-315.

4. Patel, R. M. (2022). "Environmental Impact Assessment of FR4 Sheet in the Electronics Industry." Sustainability in Manufacturing, 8(1), 75-92.

5. Zhang, Y., & Liu, H. (2021). "Innovations in FR4 Technology: Addressing High-Frequency Challenges." Microelectronics Reliability, 112, 113762.

6. Thompson, D. W. (2020). "The Evolution of FR4 Sheet: From Past to Future in PCB Manufacturing." Progress in Materials Science, 115, 100704.