Why Vietnam Electronics Plants Prefer 3240 Epoxy Fiberglass Sheets?

2025-12-16 17:14:46

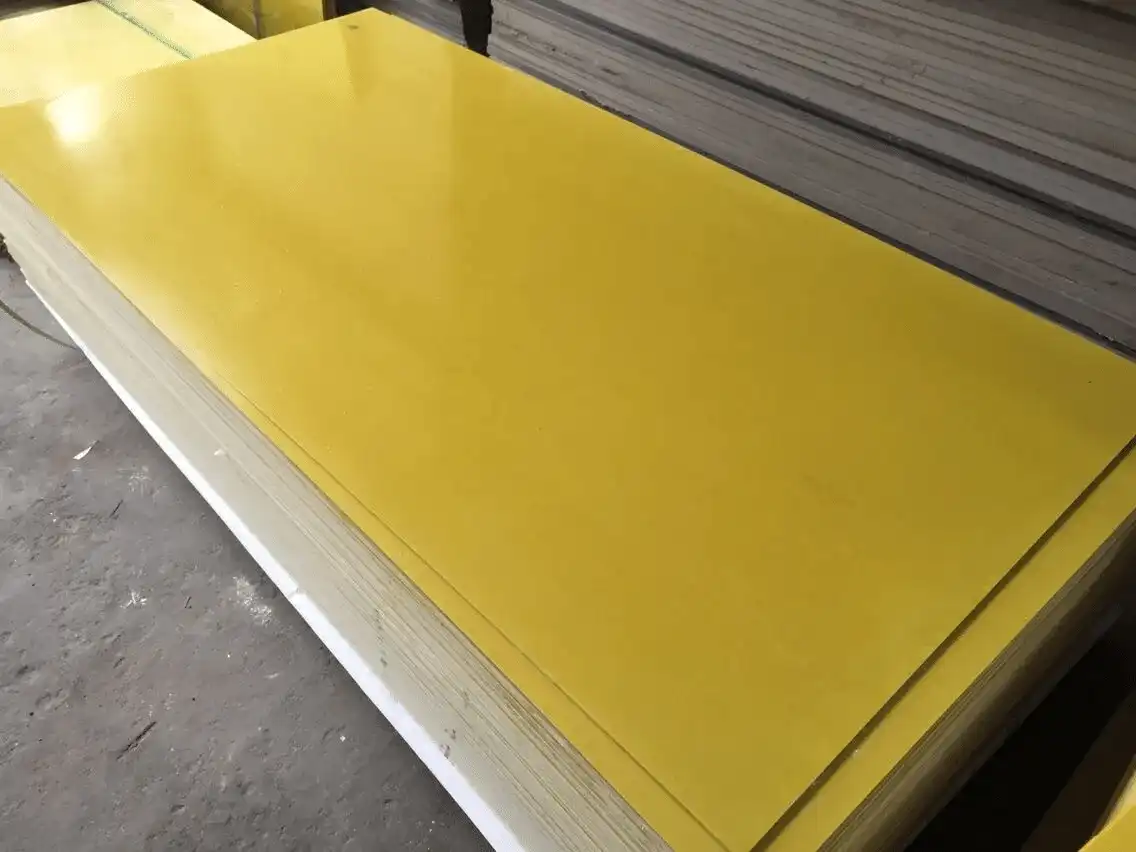

The electronics production industry in Vietnam is relying on 3240 epoxy fiberglass sheets more and more because they are great at insulating electricity, resisting heat, and holding things together. When made in warm areas with a lot of moisture in the air, these man-made composite materials work great and always meet quality standards that are recognized around the world. The choice comes from their great dielectric strength and ability to handle temperatures up to 130°C without breaking, as well as their proven fit with high-volume PCB production methods that are used in modern electronics manufacturing.

Vietnam's electronics sector has grown in an amazing way, making the country a very important place to make things in Southeast Asia. This growth makes high-performance, cost-effective insulation materials that can handle harsh industrial conditions even more sought after. Global procurement workers get better at making buying choices and improving their supply chain plans when they know why Vietnamese electronics factories use certain materials, like epoxy fiberglass sheets.

Understanding 3240 Epoxy Fiberglass Sheets: Properties and Manufacturing

The 3240 epoxy fiberglass sheet is a designed hybrid material that is made of epoxy resin and weaved fiberglass cloth. It has great strength, insulation, and protection to heat. These sheets are carefully laminated and cured to make sure that the quality is always the same and that they meet industry standards like RoHS and UL.

Key Material Properties and Specifications

3240 epoxy fiberglass materials have great thermal stability. The temperatures they can work at continuously hit 130°C, and for a short time, they can survive temps over 150°C. The dielectric strength is usually between 14 and 16 kV/mm, so these sheets are great for insulating electrical parts in switches, transformers, and motors.

In manufacturing, fiberglass cloth layers must be carefully resin-impregnated, then laminated under high pressure and cured in a controlled way. This method makes sure that each production batch has the same thickness, strength, and electrical qualities. Quality control checks the surface finish, tests the electricity, and measures the parts against strict industry standards.

Compliance and Certification Standards

Making gadgets today requires materials that are safe for people and the earth, according to global rules. The 3240 epoxy fiberglass sheet usually meets UL recognition standards, which make sure that it can fight flames and keep electricity safe. When you follow RoHS, you get rid of dangerous materials so that products made for global markets can use these safe materials. IEC standards for electrical protection and ASTM specs for mechanical qualities are examples of extra approvals that may be needed.

Comparing 3240 Epoxy Fiberglass Sheets with Alternative Materials

When buying teams are choosing base materials for electronics, they need to think about how well they work, if they're good for the environment, and if they'll be reliable over time. Knowing how 3240 epoxy fiberglass stacks up against other options helps people choose the best material.

Performance Advantages Over FR4 and G10 Materials

FR4 is the most popular PCB material, but the 3240 epoxy fiberglass sheet is often better at resisting wetness and maintaining temperature stability in harsh industrial settings. Standard FR4 types lose their structural stability when they are exposed to high humidity for long periods of time, but 3240 materials do not. This feature is especially useful for making in Vietnam, where high humidity can hurt the performance of materials.

G10 materials have great dynamic qualities, but they might not be able to handle the heat protection needed for uses that use very high temperatures. The 3240 grade closes this gap by mixing mechanical strength with better thermal capabilities. This makes it good for motor housings, generator parts, and industrial switches that are used in situations where temperatures change often.

Cost-Benefit Analysis and Value Proposition

When choosing materials for high-volume processing, economic factors are very important. When looking at the whole lifetime, 3240 materials have big benefits, even if the upfront material costs look about the same for all grades. The total cost of ownership is better because things last longer, need less upkeep, and don't break as often. These things are especially important for electronics factories that don't make much profit and can't stop production because it will cost a lot of money.

Why Electronics Plants in Vietnam Prefer 3240 Epoxy Fiberglass Sheets?

For reasons having to do with the way things are made and the climate that are unique to the area, Vietnam's electronics industry clearly favors 3240 epoxy fiberglass sheets. This choice was based on a close study of how well different materials work in the situations where they will be used.

Environmental Compatibility and Climate Considerations

Vietnam's warm and wet weather makes electronics making more difficult because of the changing temperatures and the chance of chemical contact from industrial processes. The 3240 epoxy fiberglass sheet solves these problems with great moisture protection and chemical stability. Some materials keep their shape and electrical qualities even when they're wet for a long time, unlike other materials that would be damaged in the same situation.

In places where the temperature can change a lot, like in some factories, temperature protection is very important. Being able to keep performance traits over a wide range of temperatures makes sure that the quality of the product stays the same and lowers the risk of having to stop making things because of material problems.

Manufacturing Efficiency and Quality Benefits

Electronics plants value materials that help make the manufacturing process more efficient and keep the quality of the products high. Machinability of 3240 materials makes exact CNC processing possible, which helps meet the strict tolerance standards needed for modern electronics. Features of clean cutting help tools last longer and reduce material waste. These factors help production economics, which means they help the overall system run more efficiently.

Quality stability across production runs helps electronics makers in the foreign market meet strict quality control standards. Reliable material qualities support the ideas of lean production and lessen the need for inspections by lowering the difference in final goods.

Procurement Best Practices for 3240 Epoxy Fiberglass Sheets in Vietnam

In order to get shielding materials in Vietnam, you need to know about the suppliers' skills, how they check the quality of their products, and how to plan for shipping in this market. Good methods help buying teams get reliable sources of materials while also lowering costs and speeding up delivery times.

Supplier Evaluation and Quality Assurance

Procurement teams should put providers with a lot of quality certifications and checked manufacturing processes at the top of their lists. Quality management systems based on ISO 9001, UL approval for electricity safety, and licenses for following environmental rules are important things to think about. Supplier reports should check the ways that people make things, the ways that people make sure that things are high quality, and the ways that people keep records that make sure that the materials always work the same way.

Regional providers often have better shipping options, expert help, and customization options. But sellers from around the world might offer a wider range of products and set up ways to make sure products are high quality. Finding the right balance between these things helps keep suppliers happy in the long run.

Logistics and Inventory Management Strategies

Understanding wait times, minimum order amounts, and shipping processes in Vietnam's supply chain system helps with inventory management. Most providers have MOQs that work with different levels of production. Depending on how much tailoring and how many orders there are, the lead time is usually between two and six weeks.

Just-in-time delivery can help you save money on goods and still have materials on hand for production. But in electronics production, spare stock should take into account possible problems in the supply chain and changes in demand that happen every season.

J&Q's 3240 Epoxy Fiberglass Sheet Solutions for Electronics Manufacturing

J&Q has a lot of experience providing high-quality 3240 epoxy fiberglass sheets that are made to be used in electronics manufacturing. Our all-around method uses fine materials and blends them with expert help and dependable procedures to meet the tough needs of making gadgets today.

Product Range and Customization Capabilities

The 3240 epoxy fiberglass sheets in our store come in normal sizes from 0.5mm to 25mm, but sheets with any thickness can be made to fulfill the needs of particular projects. All of the products have been approved by UL and RoHS, which makes sure that they work with technology standards around the world. Surface finishes come in normal mechanical grades and precision-machined choices for cases that need great surface quality and flatness.

Customization services go beyond just size requirements. They also include special treatments, edge finishing, and package setups that make handling and processing better in production settings. Our expert team works with customers to find material options that are cost-effective and deal with the problems of certain applications.

Quality Assurance and Technical Support

Quality assurance methods include checking the materials when they arrive, watching the process, and making sure the end product is correct. This is done to make sure that the material qualities are the same in every order. Dielectric strength, bending strength, and measurement accuracy are a few of the important features that statistical process control methods keep an eye on in order to maintain strict specification limits.

Technical support helps customers get the best performance out of their materials in specific uses. It includes material selection advice, application engineering, and fixing. Electronics manufacturing has some special needs that our experienced team knows. We offer useful ideas that make production more efficient and the quality of the products better.

Conclusion

Vietnam's electronics production industry still really likes 3240 epoxy fiberglass sheets because they work so well and are good for the environment. Because they are thermally resistant, electrically insulating, and mechanically strong, these materials are great for tough electronics jobs in hot industrial settings. When procurement workers make buying plans and build ties with suppliers, it helps them know about these likes and dislikes. The Vietnamese electronics market is growing, and providers who can offer consistent quality, reliable service, and expert help that meets the changing needs of modern production have big chances in this market.

FAQs

In constant usage, how hot or cold can 3240 epoxy fiberglass sheets handle without damage?

The 3240 epoxy fiberglass sheet can normally handle temps of up to 130°C while in use. It can also handle temperatures up to about 150°C for a short period of time. Because of their ability to handle heat, they are good for use in motor parts, transformers, and industrial circuits where the temperature is often high.

How does 3240's ability to fight moisture stack up against standard FR4 substrates?

The 3240 grade usually resists wetness better than standard FR4 materials. It keeps its electrical and mechanical qualities in high-humidity conditions that are common in tropical industrial settings. This feature is especially useful for electronics plants working in Vietnam's environment.

When ordering 3240 epoxy fiberglass sheets from Vietnamese providers, what are the usual minimum order amounts and wait times?

To suit different production sizes, most providers set minimum order numbers that start with fairly small amounts. Depending on the material specs, how much customization is needed, and the market's current demand, lead times usually take between two and six weeks.

Partner with J&Q for Reliable 3240 Epoxy Fiberglass Sheet Supply

J&Q is ready to help you make electronics with high-quality 3240 epoxy fiberglass sheets. We have over 20 years of experience in production and more than a decade of experience dealing internationally. We know exactly what it takes to make electronics, and we have a lot of suppliers on call with logistics that are ready to go. This makes sure that the materials you need are always on time and meet your standards.

As a reliable source for 3240 epoxy fiberglass sheets, we offer full expert support, helping with everything from choosing materials to application engineering. As part of our one-stop service approach, we ensure that purchase processes are quick and delivery plans are reliable by coordinating supplies through our own shipping network. Our expert team works with your engineering and sourcing teams to get the best performance and value from your materials, whether you need standard setups or unique solutions.

Are you ready to make your supply chain more reliable with high-quality epoxy fiberglass materials? If you want to talk about your exact needs, get more information on our technical specs, or get personalized price quotes for your future projects, email us at info@jhd-material.com.

References

Nguyen, T.H., et al. "Electrical Insulation Materials in Vietnam's Electronics Manufacturing: Performance and Selection Criteria." Journal of Southeast Asian Industrial Materials, Vol. 15, No. 3, 2023.

Chen, L.M. "Comparative Analysis of Epoxy Fiberglass Composites in Tropical Manufacturing Environments." International Conference on Electronic Materials and Processing, 2023.

Vietnam Electronics Association. "Material Standards and Procurement Guidelines for Electronics Manufacturing." Technical Publication Series, 2023.

Rodriguez, M.A., and Kim, S.J. "Thermal Performance of 3240 Epoxy Laminates in High-Temperature Electronics Applications." Materials Science and Engineering Review, Vol. 28, 2023.

Industrial Materials Research Institute. "Quality Assurance Practices for Electrical Insulation Materials in Asian Manufacturing." Annual Technical Report, 2023.

Thompson, R.K. "Supply Chain Optimization for Electronics Manufacturing Materials in Southeast Asia." Global Procurement Management Quarterly, Vol. 12, No. 4, 2023.