ABOUT J&Q New Composite Materials Company

J&Q New Composite Materials Company

is controlled by Jinghong Group, located in Xi'an. Hebei Jinghong Electronic Technology Co., Ltd and Hongda Insulation Materials Plant are both located in Hebei province. Total covers an area of 36300 square meters. Hongda was founded in 2002, And devote to research and production of insulation materials for more than 20 years. Due to the market demand being bigger, Jinghong Electronic was established in 2018.-

Year Experience

22 Years+

-

Production Lines

14+

-

Cover Area

36300m2

-

Experienced Staff

200+

-

Customer Services

24h

-

Exported Countries

80

1

Fully Automatic Equipment

2

Productive Strength

3

Production line

Hot Products

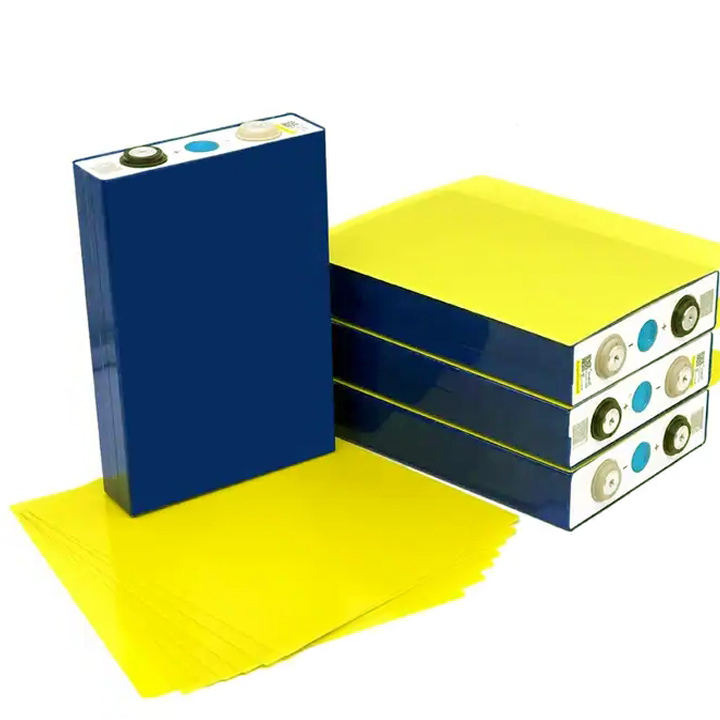

Durostone Sheet

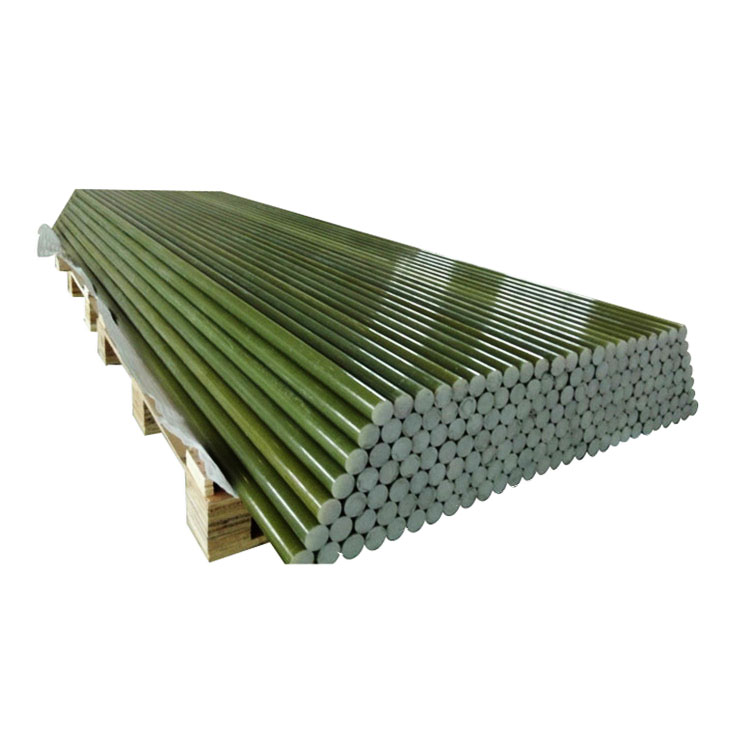

Insulation Tube/Rod

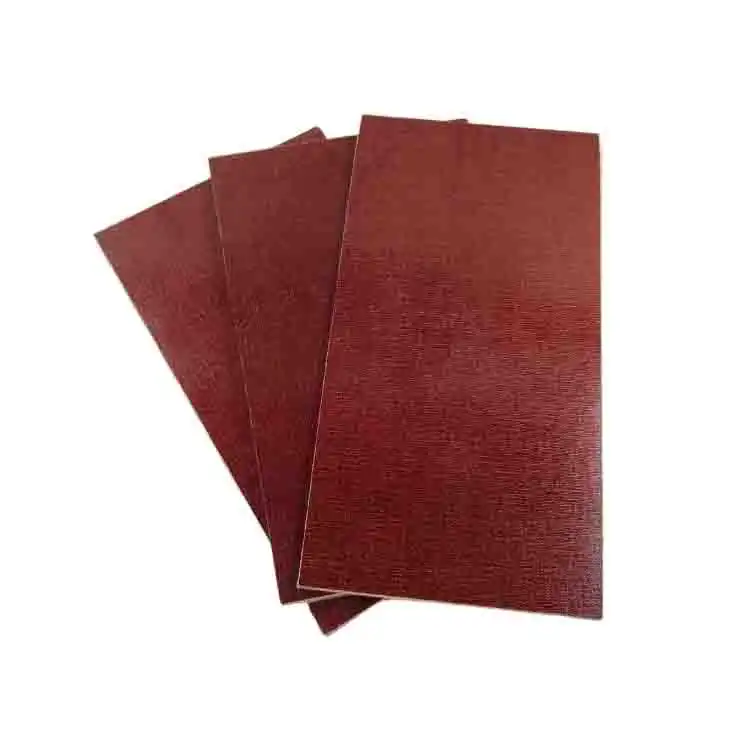

Phenolic Cotton Board

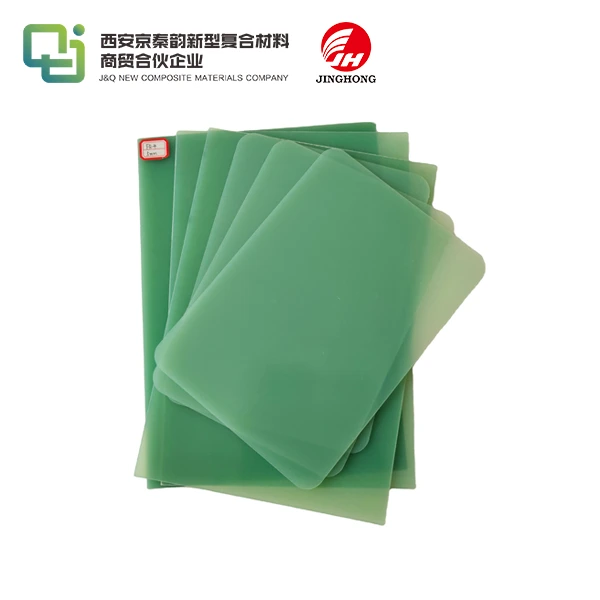

3240 Epoxy Board

Insulation Rod

FR4 Epoxy Board

Write to us

Send us your question via the contact form, and we will respond to

you as soon as we can.

We are ready to help you 24/7

Latest News

Location Details

Phone

+8617782915701Tel/Whatsapp

+8617782915701Email

info@jhd-material.com