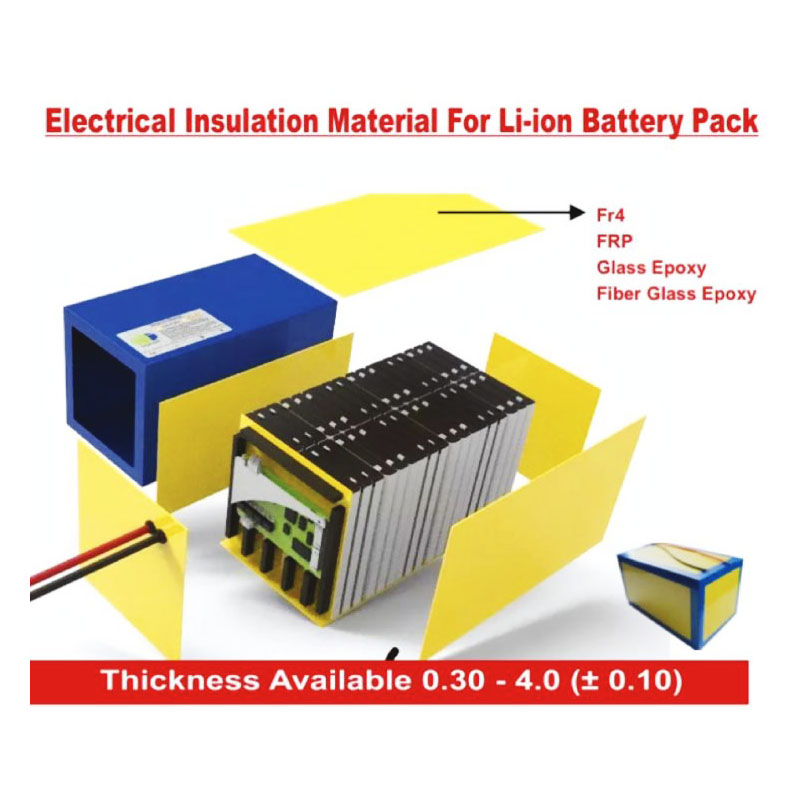

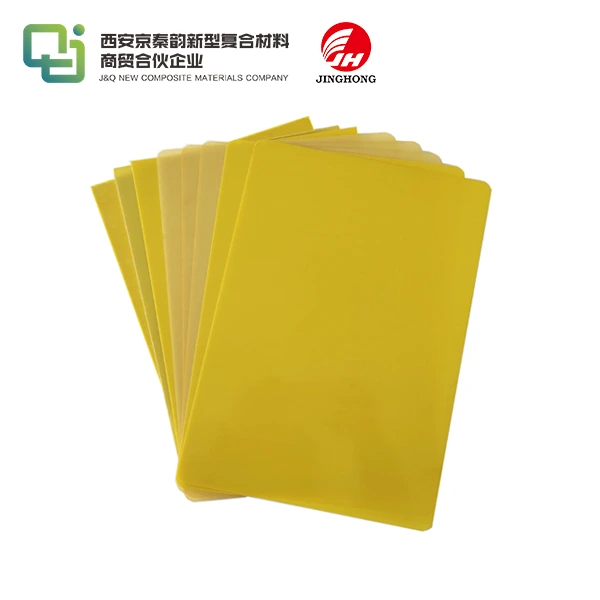

Epoxy Sheet For Lithium Battery Pack

Basic Information:

Brand: JingHong

Materials: Alkali-free Cloth/medium-alkali Cloth + Epoxy Resin

Nature Color: Yellow

Thickness: 0.5mm --- 100mm

Size: 1020mm*2020mm (Regular)

Grade: A,B+,SR,B

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment:T/T

MOQ:500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Epoxy Sheet For Lithium Battery Pack - Professional Insulation Solutions

Our Epoxy Sheet For Lithium Battery Pack conveys extraordinary execution and security for present day vitality capacity frameworks. Made from premium alkali-free cloth and epoxy gum, these specialized sheets give the culminate adjust of electrical separator, warm resistance, and mechanical quality your battery packs need.

|

|

|

Product Description from the Supplier

JingHong brand epoxy sheets speak to cutting-edge composite fabric innovation. Each sheet combines carefully chosen alkali-free or medium-alkali cloth with high-grade epoxy gum. This combination makes a vigorous cover fabric that meets the requesting prerequisites of lithium battery manufacturing.

Our fabricating office produces 30,000 tons yearly, guaranteeing reliable supply for your generation needs. Each sheet experiences thorough quality control to keep up the most elevated standards.

Description

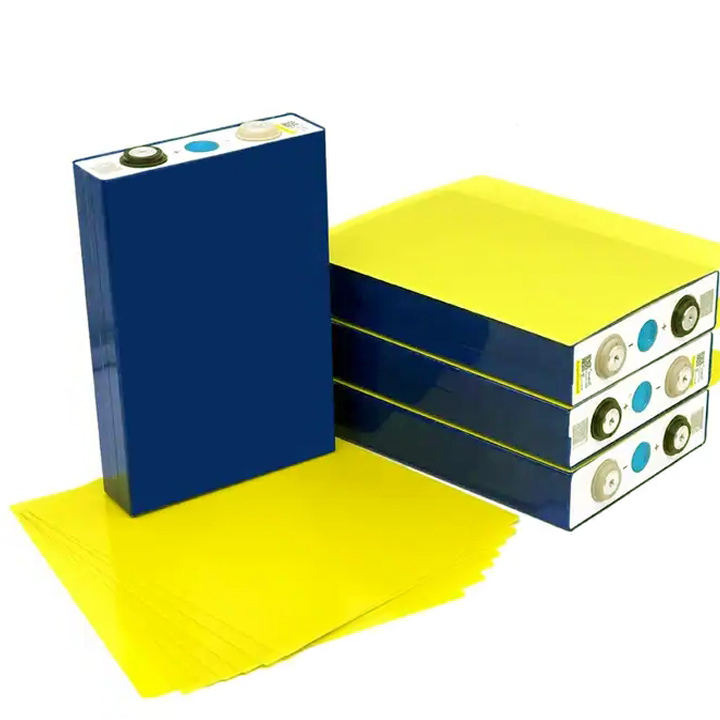

These yellow-colored cover sheets offer predominant electrical properties and dimensional solidness. The fiberglass cloth support gives great mechanical quality, whereas the epoxy tar network guarantees solid electrical cover. Your battery pack plans will advantage from steady execution over different working conditions.

The fabric shows great resistance to chemicals and dampness. This makes it perfect for applications where long-term unwavering quality is essential.

Product Availability

Available Specifications:

| Attribute | Details |

|---|---|

| Thickness Range | 0.5mm to 100mm |

| Standard Size | 1020mm × 2020mm |

| Grades Available | A, B+, SR, B |

| Minimum Order | 500KG |

| Lead Time | Contact us for current availability |

| Annual Capacity | 30,000 tons |

Custom sizes and thicknesses can be orchestrated to meet your particular requirements.

Technical Data for FR4

| Test Items | Unit | Test Result | Test Method |

| Bending Strength Perpendicular to Laminations |

MPa | 571 | GB/T 1303.4-2009 |

| Compressive Strength Perpendicular to Laminations compressive |

MPa | 548 | |

| Parallel Layer Impact Strength (Simply Supported Beam, Gap) |

KJ/m3 | 57.3 | |

| Tensile Strength | MPa | 282 | |

| Vertical Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, q25mm/p75mm cylinder electrode system) |

kV/mm | 16.7 | |

| Parallel Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil 20s step by step boost, p130mm/ (p130mm flat plate electrode system) |

kV | >100 | |

| Relative Permittivity (50HZ) | 5.40 | ||

| Dielectric Dissipation Factor (50HZ) | 7.2*10-3 | ||

| Insulation Resistance after Soaking | Q | 2.2*1013 | |

| Density | g/cm3 | 2.01 | |

| Water Absorption | mg | 5.3 | |

| Barcol Hardness | 76 | GB/T 3854-2005 | |

| Flammability | Grade | V-0 | GB/T 2408-2008 |

| REMARK: ·NO.2 the sample height is (5.00~5.04) mm; · NO.5 the sample thickness is (2.02~2.06) mm; ·NO.6 the sample size is (100.50~100.52)mm*(25.10~25.15)mm*(5.02~5.06)mm thickness, The electrode spacing is (25.10~25.15)mm; ·NO.11 the sample size is (49.86~49.90)mm*(49.60~49.63)mm*(2.53~2.65)mm; ·NO.13 the sample size is (13.04~13.22)mm*(3.04~3.12)mm thickness. |

|||

Key Features

✓ Predominant Electrical Cover - Anticipates brief circuits in battery assemblies

✓Tall Temperature Resistance - Works dependably up to 130℃

✓ Mechanical Quality - Withstands get together weights and vibrations

✓ Chemical Resistance - Ensures against electrolyte exposure

✓ Dimensional Solidness - Keeps up shape beneath warm cycling

✓ Lightweight Plan - Minimizes affect on in general battery weight

✓ Simple Machining - Cuts and shapes cleanly for exact fitting

Standards

Our epoxy sheets comply with industry-standard determinations for electrical cover materials. Review B 3240 assignment guarantees compatibility with existing battery plan conventions. Each clump meets strict quality benchmarks for electrical, warm, and mechanical properties.

The fabricating handle takes after universal quality administration frameworks. This guarantees steady item execution over all shipments.

Technical Features: Product Safety Control

Electrical Properties:

- High dielectric quality avoids electrical breakdown

- Low dielectric misfortune keeps up efficiency

- Excellent circular segment resistance upgrades safety

Thermal Management:

- Operating temperature up to 130℃

- Good warm conductivity for warm dissipation

- Flame-resistant formulation

Quality Assurance:

Every Epoxy Sheet For Lithium Battery Pack experiences comprehensive testing some time recently shipment. Our quality control group screens electrical properties, dimensional precision, and surface quality. This multi-step confirmation prepare guarantees you get materials that meet your correct specifications.

Product Application

Primary Applications:

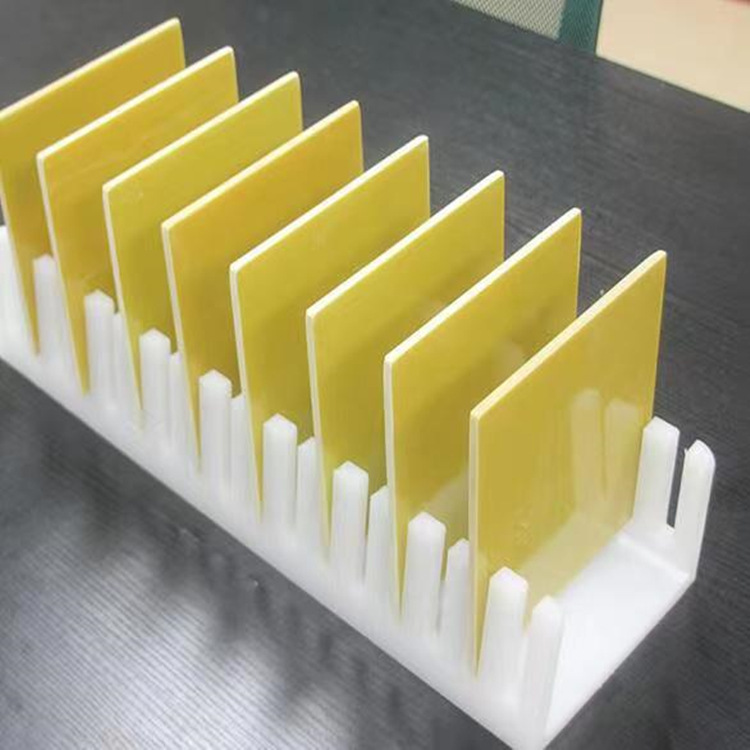

- Lithium-ion battery pack insulation

- Cell partition barriers

- Thermal administration components

- Electrical segregation layers

- Structural back elements

Industry Usage:

- Electric vehicle batteries

- Energy capacity systems

- Power device batteries

- Consumer electronics

- Industrial battery applications

The flexible nature of these sheets makes them appropriate for both model improvement and mass generation requirements.

OEM Service

We get it that each battery plan has interesting prerequisites. Our experienced building group works closely with you to create customized arrangements. Whether you require particular measurements, uncommon grades, or altered properties, we can adjust our product to coordinate your needs.

Custom Services Include:

- Precision cutting and shaping

- Special thickness requirements

- Modified electrical properties

- Custom packaging solutions

- Technical support and consultation

Certification

FAQ

Q: Can these sheets be used for lithium battery insulation?

A: Yes, Grade B 3240 epoxy boards are specifically designed and commonly used for battery insulation applications.

Q: What is the maximum operating temperature?

A: Our epoxy sheets can safely operate at temperatures up to 130℃, making them suitable for most battery applications.

Q: What materials are used in manufacturing?

A: We use premium alkali-free cloth or medium-alkali cloth combined with high-quality epoxy resin for optimal performance.

Q: How do I determine the right thickness for my application?

A: Contact our technical team with your specific requirements. We'll recommend the optimal thickness based on your voltage levels and spacing constraints.

Q: Are custom sizes available?

A: Yes, we can provide custom cutting and sizing services to meet your exact specifications.

Contact Us

Ready to enhance your battery pack design with premium insulation materials? Our technical team is here to help you select the perfect Epoxy Sheet For Lithium Battery Pack for your application.

Get in touch today:

📧 Email: info@jhd-material.com

Let us accomplice with you to make more secure, more dependable lithium battery arrangements. Contact us for specialized determinations, custom cites, or test demands.

Send Inquiry

_1764574111651.jpg)

_1764574111612.jpg)

_1764574111544.jpg)