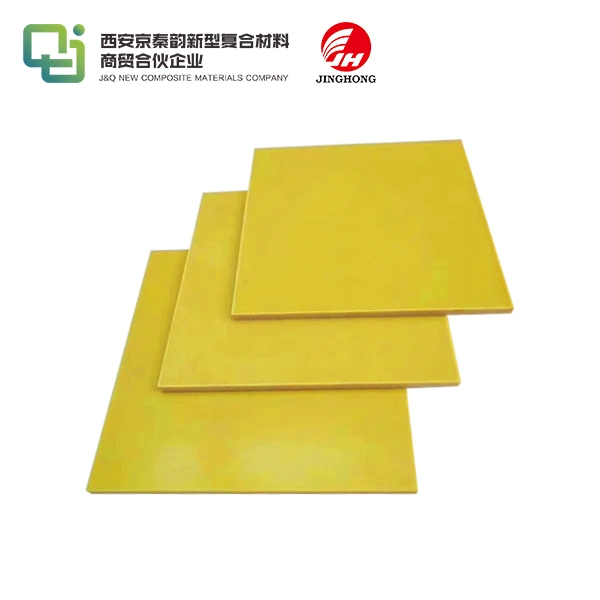

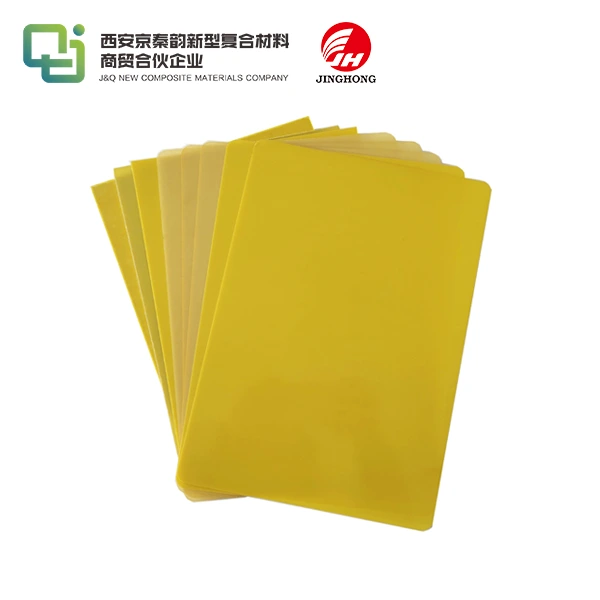

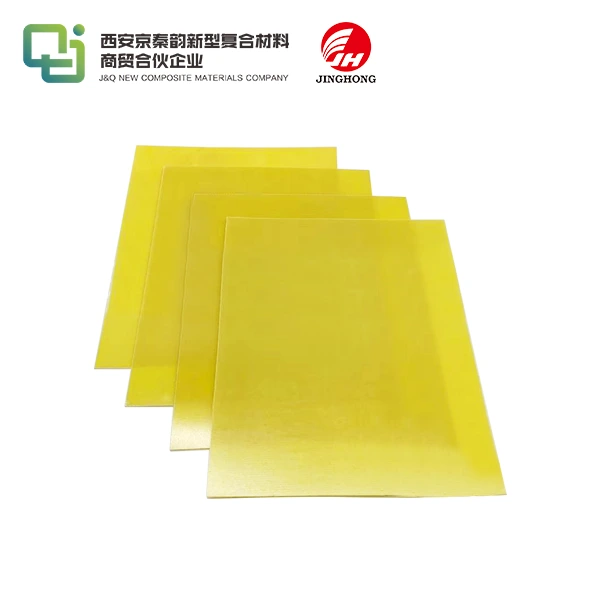

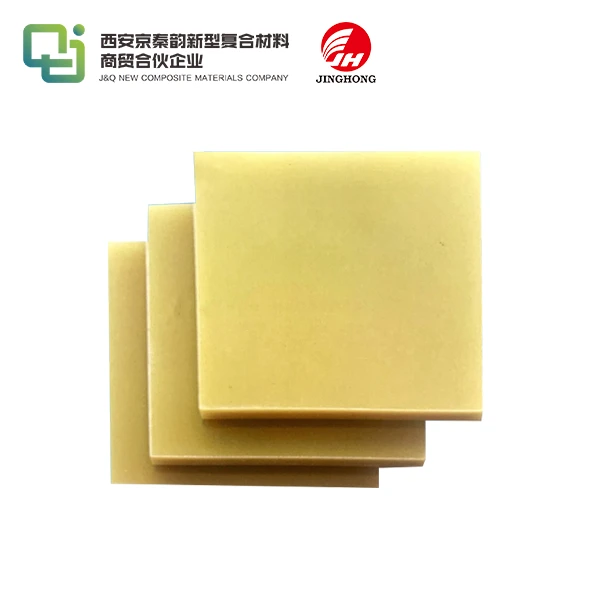

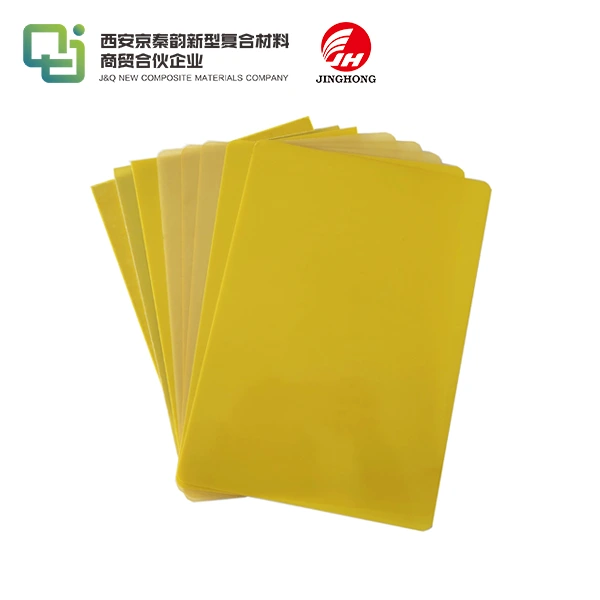

3240 Epoxy Resin Glass Fibre Laminated Sheet

Basic Information:

Brand: Hongda

Materials: Epoxy Resin, Phenolic Resin

Nature Color: Yellow

Thickness: 0.3mm --- 100mm

Size: 1020mm*2020mm (Regular)

Packaging: Regular packing, Protect by Pallet

Productivity: 13000 Tons per year

Transportation: Ocean, Land, Air

Payment:T/T

MOQ:500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Production Description

3240 Epoxy Resin Glass Fiber Laminated Sheet is a composite material composed of woven fiberglass cloth with an epoxy resin and phenolic resin. It has high dielectric strength, radian resistance, high tensile strength, low cold flow or creep, dimension stability, low dissipation factor and high impact strength. Also, 3240 Epoxy Glass Fiber Laminate Board has great chemical resistance, so it can Withstand a variety of chemical solvents and acid erosion.

Application

This excellent properties of Epoxy Fiberglass Laminated Sheets 3240 alone with good processing characteristic make the materials apply into lots of industries. This material can be used in electrical equipment, aerospace condition, rocket cases, antenna insulators, test boards, end plates, cryogenic insulations, terminal boards, cutting model.

Technical Data for 3240 GradeB

|

NO |

TEST ITEMS |

UNIT |

TEST RESULT |

TEST METHOD |

|

|

1 |

Density |

g/cm3 |

2.07 |

GB/T 1303.2-2009 |

|

|

2 |

Water Absorption |

mg |

6.0 |

||

|

3 |

Bending Strength Perpendicular to Laminations |

A |

MPa |

203 |

|

|

B |

192 |

||||

|

4 |

Modulus of Elasticity in Flexure |

A |

MPa |

2.12*104 |

|

|

B |

2.38*104 |

||||

|

5 |

Parallel Layer Impact Strength (Simply Supported Beam, Gap) |

A |

KJ/m² |

47.4 |

|

|

B |

35.8 |

||||

|

6 |

Parallel Layer Shear Strength |

A |

MPa |

49.8 |

|

|

B |

52.7 |

||||

|

7 |

Tensile Strength |

A |

MPa |

147 |

|

|

B |

121 |

||||

|

8 |

Compressive Strength Perpendicular to Laminations compressive |

MPa |

438 |

||

|

9 |

Insulation Resistance after Soaking |

Ω |

2.0*109 |

||

|

10 |

Vertical Layer Breakdown Voltage (90℃ + 2℃ oil, 20s step by step boost) |

MV/m |

8.6 |

||

|

11 |

Parallel Layer Breakdown Voltage (90℃ + 2℃ oil, 20s step by step boost) |

kV |

28.0 |

||

|

12 |

Flammability |

- |

V-1 |

||

|

13 |

Deflection Temperature under Load |

A |

℃ |

>140 |

|

|

B |

>140 |

||||

|

14 |

Adhesive Strength |

N |

6324 |

GB/T 1303.6-2009 |

|

|

REMARK: 1. NO.2 the sample size is 50mm*50mm*50mm; 2. NO.8 the sample height is (9.05~9.56) mm; 3. NO.10 the sample thickness is (2.91~2.95)mm; 4. NO.11 the sample size is 100.00mm*5.08mm*24.10mm; |

|||||

|

|

|

|

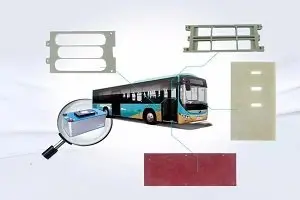

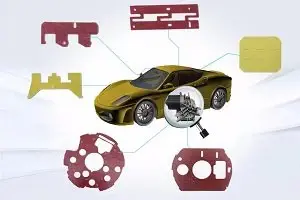

| Capacitor Industry | Lithium Battery Pack | New Energy Vehicle Industry |

It can be machined to various shapes as insulation parts in which the mechanical and electrical properties is required.

Factory

Certification

|

|

Packaging and Shipping

Regular packing, Protect by Pallet

Send Inquiry