Solder Pallet Material

Basic Information:

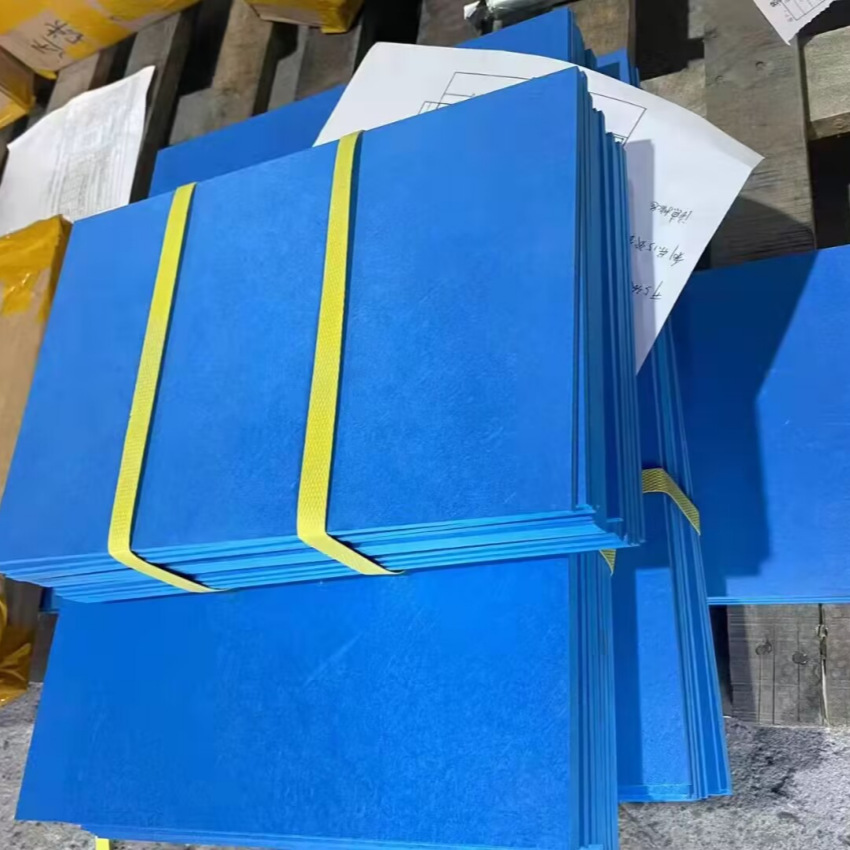

Brand: JingHong

Thinkness:3-50mm

Color:Black, Grey, Blue

Characteristics:

-Good Anti-static property

-High strength and good machinability

-High temperature resistance

-Tight machining tolerance

-Chemical resistant

-Long life cycle

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Solder Pallet Material - High-Performance Anti-Static Solutions for Electronics Manufacturing

Product Descriptions from the Supplier

Our Solder Pallet Material from JingHong brand conveys remarkable execution for hardware fabricating applications. With thickness choices extending from 3-50mm and accessible in dark, dark, and blue colors, these materials give the toughness and exactness your generation line requests. Each sheet comes in standard 1m x 2m measurements, flawlessly suited for mechanical applications.

Description

Our progressed composite materials offer prevalent anti-static properties combined with amazing machinability. You'll discover these materials idealize for making custom beds that ensure touchy electronic components amid patching forms. The high-strength composition guarantees reliable execution indeed beneath requesting generation conditions.

Durostone Resistance Test

|

NO |

TEST ITEMS |

UNIT |

DEMAND |

TEST RESULT |

TEST METHOD |

|

1 |

Rockwell hardness |

_ |

_ |

M114 |

GB/T 3398.2-2008 |

|

2 |

GTT |

℃ |

_ |

136 |

GB/T 22567-2008 |

|

3 |

Density |

g/cm3 |

2.01 |

GB/T 1303.2-2009 |

|

|

4 |

Hydroscopicity |

mg |

_ |

24.2 |

|

|

5 |

Vertical Laminar Bending Strength (23℃土 2℃) |

MPa |

|

361 |

|

|

6 |

Vertical Laminar Bending Strength (155℃土 2℃) |

MPa |

|

158 |

|

|

7 |

Vertical Laminar Bending Strength (180℃土 2℃) |

MPa |

_ |

84.4 |

|

|

8 |

Elastic Modulus of Vertical Laminar Bending (23℃土 2℃) |

MPa |

|

2. 15×104 |

|

|

9 |

Elastic Modulus of Vertical Laminar Bending (155℃土 2℃) |

MPa |

|

1.26×104 |

|

|

10 |

Elastic Modulus of Vertical Laminar Bending (180℃土 2℃) |

MPa |

|

9.95×103 |

|

|

11 |

Operating Temperature (260℃土 5℃) |

No stratified cracking |

Methods Provided by the Principal |

||

|

12 |

Transient Temperature Resistance (350℃土 10℃) |

_ |

_ |

No stratified cracking and the appearance was not changed |

|

|

13 |

Surface Resistivity |

Ω |

1.5×107 |

GB/T 31838.3-2019 |

|

|

14 |

Coefficient of Linear Thermal Expansion (20℃~60℃) |

10-6/k |

|

12.5 |

GB/T 1036-2008 |

|

REMARK:The size of the fourth item “Hydroscopicity” is (60.01~61. 15)mm×(60.02~60.21)mm×4.00mm |

|||||

Product Availability

Currently accessible in three appealing color options:

- Black - Classic mechanical appearance

- Grey - Proficient clean look

- Blue - Simple recognizable proof and sorting

Standard sheet measurements of 1m x 2m are prepared for prompt shipping. Custom cutting administrations accessible upon ask with your particular drawings or measurements.

Key Features

Anti-Static Security: Built-in anti-static properties protect delicate electronic components all through the fabricating process.

Temperature Resistance: Withstands high-temperature patching operations without debasement or warping.

Precision Machining: Tight resistance capabilities permit for precise cutting and forming to meet your correct specifications.

Chemical Resistance: Amazing resistance to flux, solvents, and cleaning chemicals commonly utilized in hardware manufacturing.

Durability: Amplified benefit life diminishes substitution costs and generation downtime.

Versatile Thickness Choices: Select from 3mm to 50mm thickness to coordinate your particular application requirements.

Technical Features: Product Safety Control

Electrostatic Release (ESD) Assurance: Controlled surface resistivity avoids inactive buildup that might harm touchy components.

Material Solidness: Keeps up auxiliary keenness over wide temperature ranges commonplace in patching operations.

Non-Contaminating: Clean fabricating handle guarantees no ionic defilement that may influence electronic assemblies.

Dimensional Soundness: Negligible warm extension guarantees exact fit and reliable execution amid temperature cycling.

Product Application

Perfect for different gadgets fabricating applications:

- Wave Fastening Beds: Make custom installations for PCB get together lines

- Selective Patching: Accuracy concealing for focused on patching operations

- Component Testing Installations: Solid stages for quality control processes

- Assembly Dances: Tough tooling for tedious fabricating tasks

- Protective Obstructions: Shield delicate zones amid fabricating processes

Whether you're working with little model runs or high-volume generation, our Solder Pallet Material adjusts to your particular needs. Numerous producers select these materials for their reliable quality and dependable

OEM Service

We get it that each fabricating operation has interesting necessities. Our experienced group works closely with you to create custom arrangements. Essentially give your drawings, details, or dimensional prerequisites, and we'll precision-cut materials to your correct needs.

Custom Cutting Services Include:

- CNC machining for complex shapes

- Precision penetrating and routing

- Edge wrapping up options

- Small to expansive amount orders

Our specialized bolster group helps all through the plan handle, making a difference optimize your tooling for greatest effectiveness and longevity.

Certification

FAQ

Q: What thickness should I choose for wave soldering applications?

A: For most wave soldering pallets, 6-10mm thickness provides excellent durability while remaining cost-effective.

Q: Can these materials withstand lead-free soldering temperatures?

A: Yes, our materials are specifically designed to handle the higher temperatures required for lead-free soldering processes.

Q: How do I maintain the anti-static properties over time?

A: Regular cleaning with approved ESD-safe cleaners maintains optimal anti-static performance throughout the material's service life.

Q: What's the typical lead time for custom cutting?

A: Standard custom cutting typically ships within 5-7 business days after receiving your specifications.

Q: Are samples available for testing?

A: Yes, we provide sample pieces so you can evaluate material properties in your specific application before placing larger orders.

Using our proven Solder Pallet Material guarantees your fabricating forms run easily whereas securing important electronic components. The combination of toughness, exactness, and anti-static assurance makes these materials the shrewd choice for present day gadgets production.

Contact Us

Ready to improve your patching operations with premium materials? Our specialized group stands prepared to offer assistance you select the right determinations for your application.

Get in touch today: info@jhd-material.com

We're here to reply your questions and give point by point determinations for your particular necessities. Let us offer assistance you discover the culminate arrangement for your fabricating needs.

Send Inquiry

_1754967691873.webp)