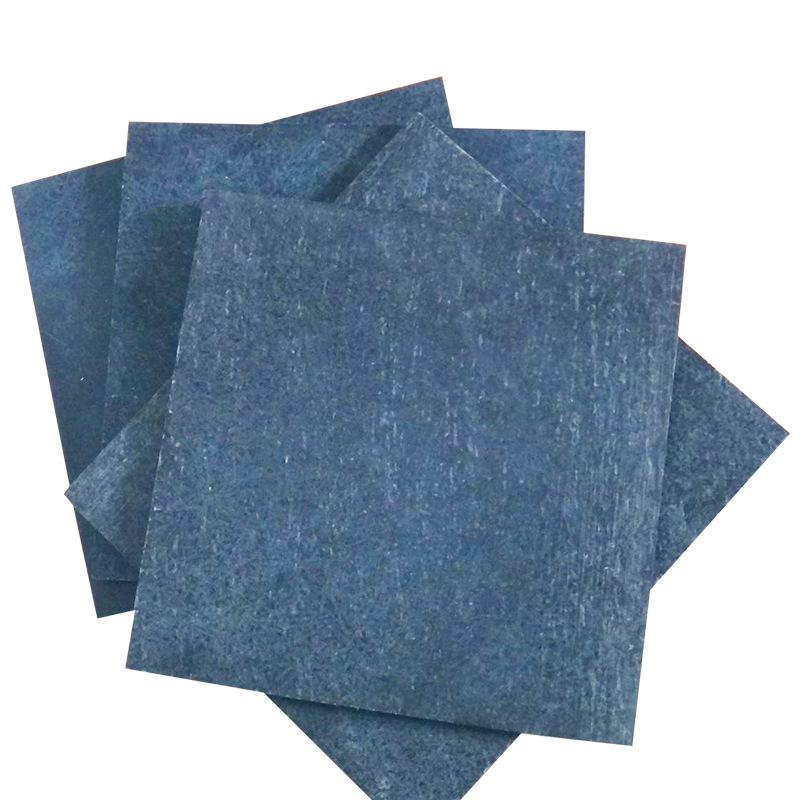

ESD Durostone Sheet

Basic Information:

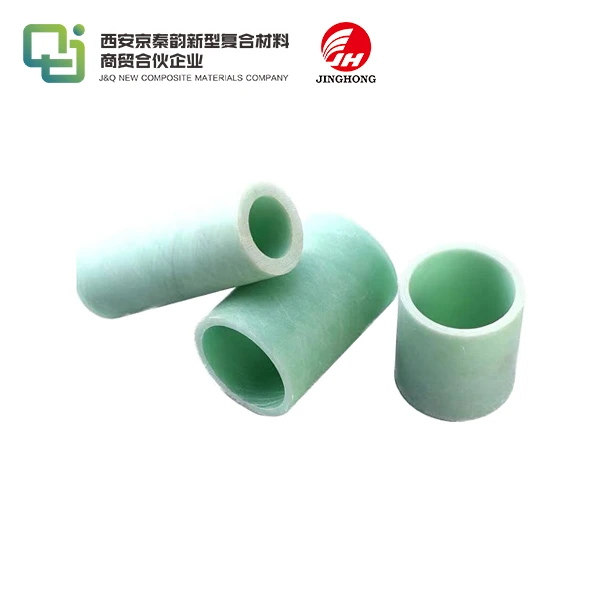

Brand: JingHong

Thinkness:3-50mm

Color:Black, Grey, Blue

Characteristics:

-Good Anti-static property

-High strength and good machinability

-High temperature resistance

-Tight machining tolerance

-Chemical resistant

-Long life cycle

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

ESD Durostone Sheet: Advanced Static Control for Precision Manufacturing

As a leading manufacturer of high-performance composite materials, J&Q New Composite Material Group Co., Ltd proudly offers top-quality ESD durostone sheets. Our advanced production facilities and 20+ years of experience ensure superior static dissipative properties, exceptional durability, and consistent performance. Choose J&Q for reliable ESD protection in your critical manufacturing processes.

Product Description

Our items give fabulous electrostatic release security for touchy electronic components and exactness fabricating situations. These flexible sheets combine the quality of epoxy gum with inactive dissipative properties, making them perfect for different applications in hardware, aviation, and car businesses.

Technical Specifications

- Material: Epoxy resin reinforced with woven glass fabric

- Surface Resistivity: 106 - 109 ohms/square

- Volume Resistivity: 106 - 109 ohm-cm

- Thickness Range: 0.5mm - 50mm

- Standard Sheet Size: 1220mm x 2440mm (customizable)

- Temperature Resistance: Up to 180°C (short-term)

- Dielectric Strength: >20 kV/mm

- Water Absorption: <0.1%

- Flexural Strength: >400 MPa

- Tensile Strength: >300 MPa

Applications

- ESD-safe workstations and assembly areas

- PCB handling and transport fixtures

- Semiconductor manufacturing equipment

- Cleanroom tools and fixtures

- Aerospace and automotive precision components

- Medical device assembly jigs

- Antistatic flooring and wall panels

- Industrial automation equipment

How to Use?

- Determine the required dimensions and thickness for your application

- Cut the ESD durostone sheet to size using appropriate tools (e.g., CNC router, waterjet cutter)

- Machine or drill holes as needed for assembly

- Clean the surface with isopropyl alcohol before use

- Implement in your manufacturing process, ensuring proper grounding connections

Why Choose Us?

- Superior Quality: Our state-of-the-art production facilities and rigorous quality control ensure consistent, high-performance products.

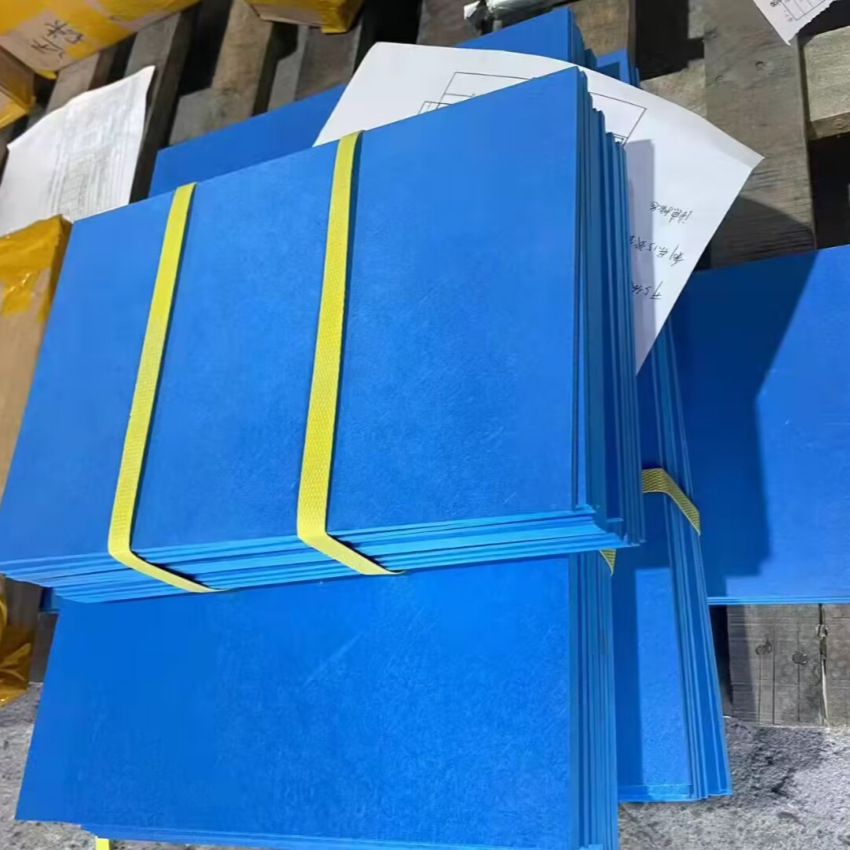

- Customization: We offer tailored solutions to meet your specific requirements, including custom sizes, thicknesses, and colors.

- Technical Expertise: Our team of experienced engineers provides expert guidance on material selection and implementation.

- Global Reach: With exports to Russia, Southeast Asia, the United States, Europe, and beyond, we have a proven track record of international success.

- Logistics Support: Our in-house logistics company ensures efficient, timely delivery of your orders.

- Competitive Pricing: Benefit from our large-scale production capabilities and direct factory pricing.

- Sustainability Focus: We continuously work to improve our manufacturing processes and develop eco-friendly material options.

Qualification Certifications

- ISO 9001:2015 Quality Management System

- RoHS Compliant

- REACH Compliant

- UL 94 V-0 Flammability Rating

Transaction Feedback

"J&Q's products have significantly improved our PCB handling process. The consistent quality and excellent static dissipation properties have reduced our defect rates by 15%." - Electronics Manufacturer, USA

"We've been using J&Q's products for our cleanroom fixtures for over two years. Their technical support and customization options have been invaluable to our operations." - Medical Device Manufacturer, Germany

Exhibition

FAQ

Q: What is the minimum order quantity for products?

A: Our standard MOQ is 10 sheets, but we can accommodate smaller orders for sample testing.

Q: Can you provide material test reports for your products?

A: Yes, we provide comprehensive test reports with each order, detailing electrical, mechanical, and thermal properties.

Q: How long is the lead time for custom orders?

A: Typical lead times for custom orders range from 2-4 weeks, depending on specifications and quantity.

Q: Are your products recyclable?

A: While not easily recyclable due to their composite nature, we offer a take-back program for larger customers to ensure responsible disposal.

Q: Can the products be used outdoors?

A: Our sheets are primarily designed for indoor use. For outdoor applications, we recommend discussing your specific requirements with our technical team.

Contact Us

Ready to enhance your ESD protection with high-quality durostone sheets? Contact our expert team today for personalized support and quotations.

Email: info@jhd-material.com

Experience the difference of J&Q's ESD durostone sheets in your precision manufacturing processes. With our commitment to quality, customization, and customer support, we're your ideal partner for static control solutions. Reach out now to discuss how we can meet your specific ESD protection needs.

Send Inquiry