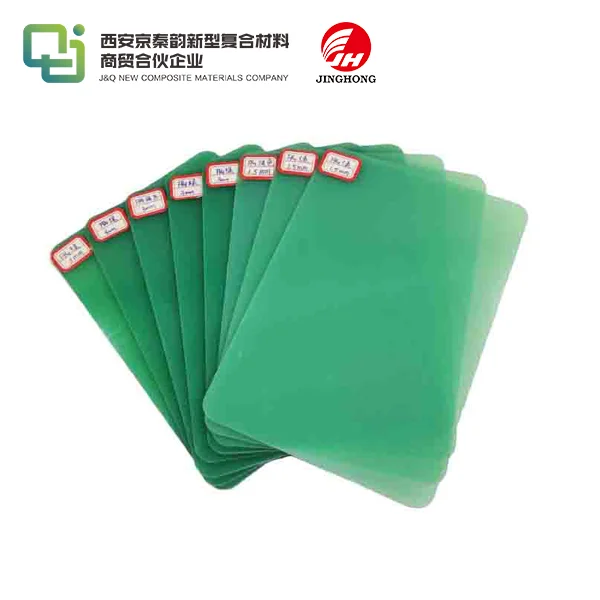

G10 Epoxy Fiberglass Board

Basic Information:

Brand: JingHong

Materials: 7628 Electronic Cloth + Epoxy Resin

Flame Retardant Grade: UL94V0

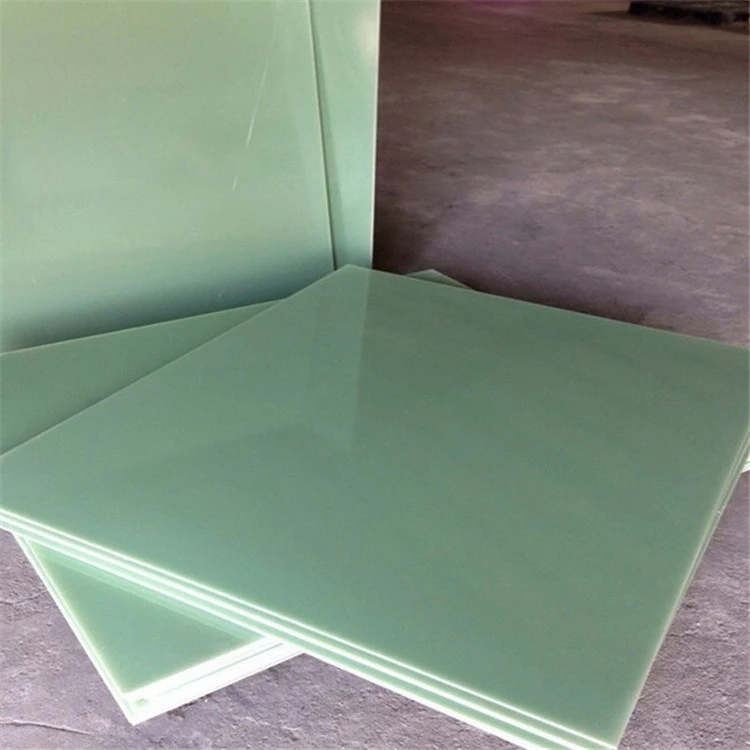

Nature Color: Light Green,Yellow,Black

Thickness: 0.3mm --- 100mm

Regular Size: 1020mm*1220mm,1220mm*2440mm,1020mm*2020mm

Custom Size: 1030mm*2030mm, 1220mm*2440mm, 1030mm*1030mm 1030mm*2070mm

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment: T/T

MOQ: 500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

G10 Epoxy Fiberglass Board - Premium Industrial Insulation Solution

Our G10 Epoxy Fiberglass Board conveys extraordinary execution for your mechanical applications. Fabricated with high-quality 7628 electronic cloth and premium epoxy tar, this flexible fabric offers extraordinary mechanical quality and electrical properties. Whether you require standard measurements or custom sizes, JingHong brand guarantees reliable quality that meets your extend necessities. With fire retardant review UL94V0 certification, you can believe our sheets for basic electrical applications.

Product Description

Our premium fiberglass sheets combine progressed materials building with dependable fabricating forms. The composite structure highlights 7628 electronic cloth fortification with epoxy gum framework, making a tough arrangement for requesting situations. Accessible in numerous colors and thicknesses, these sheets adjust to different mechanical needs whereas keeping up fabulous dimensional stability.

Product Availability

| Attribute | Details |

|---|---|

| Brand | JingHong |

| Materials | 7628 Electronic Cloth + Epoxy Resin |

| Colors | Light Green, Yellow, Black |

| Thickness Range | 0.3mm - 100mm |

| Production Capacity | 30,000 tons annually |

| Minimum Order | 500KG |

| Standard Dimensions | 1020mm × 1220mm, 1220mm × 2440mm, 1020mm × 2020mm |

| Custom Sizes Available | 1030mm × 2030mm, 1030mm × 1030mm, 1030mm × 2070mm |

| Maximum Width | 3000mm |

Key Features

Superior Electrical Separator: Great dielectric properties guarantee dependable execution in high-voltage applications.

Mechanical Quality: Exceptional flexural and affect resistance withstand requesting operational conditions.

Temperature Soundness: Keeps up properties over wide temperature ranges for steady performance.

Chemical Resistance: Stands up to oils, solvents, and most mechanical chemicals.

Dimensional Exactness: Tight resilience control guarantees culminate fit in your assemblies.

Flame Retardant: UL94V0 rating gives upgraded security for electrical applications.

Standards

Our fabricating forms comply with universal quality measures. Each G10 Epoxy Fiberglass Board experiences thorough testing to guarantee steady execution. The UL94V0 fire retardant rating meets exacting security prerequisites for electrical and electronic applications.

Technical Data for G10

|

NO |

TEST ITEMS |

UNIT |

TEST RESULT |

TEST METHOD |

|

1 |

Bending Strength Perpendicular to Laminations |

MPa |

571 |

GB/T 1303.4-2009 |

|

2 |

Compressive Strength Perpendicular to Laminations compressive |

MPa |

548 |

|

|

3 |

Parallel Layer Impact Strength (Simply Supported Beam, Gap) |

KJ/m² |

57.3 |

|

|

4 |

Tensile Strength |

MPa |

282 |

|

|

5 |

Vertical Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ25mm/φ75mm cylinder electrode system) |

kV/mm |

16.7 |

|

|

6 |

Parallel Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ130mm/φ130mm flat plate electrode system) |

kV |

>100 |

|

|

7 |

Relative Permittivity (50HZ) |

- |

5.40 |

|

|

8 |

Dielectric Dissipation Factor (50HZ) |

7.2*10-3 |

||

|

9 |

Insulation Resistance after Soaking |

Ω |

2.2*1013 |

|

|

10 |

Density |

g/cm3 |

2.01 |

|

|

11 |

Water Absorption |

mg |

5.3 |

|

|

12 |

Barcol Hardness |

- |

76 |

GB/T 3854-2005 |

|

13 |

Flammability |

Grade |

V-1 |

GB/T 2408-2008 |

|

REMARK: 1. NO.2 the sample height is (5.00~5.04) mm; 2. NO.5 the sample thickness is (2.02~2.06) mm; 3. NO.6 the sample size is (100.50~100.52)mm*(25.10~25.15)mm*(5.02~5.06)mm thickness, The electrode spacing is (25.10~25.15)mm; 4. NO.11 the sample size is (49.86~49.90)mm*(49.60~49.63)mm*(2.53~2.65)mm; 5. NO.13 the sample size is (13.04~13.22)mm*(3.04~3.12)mm thickness. |

||||

Technical Features: Product Safety Control

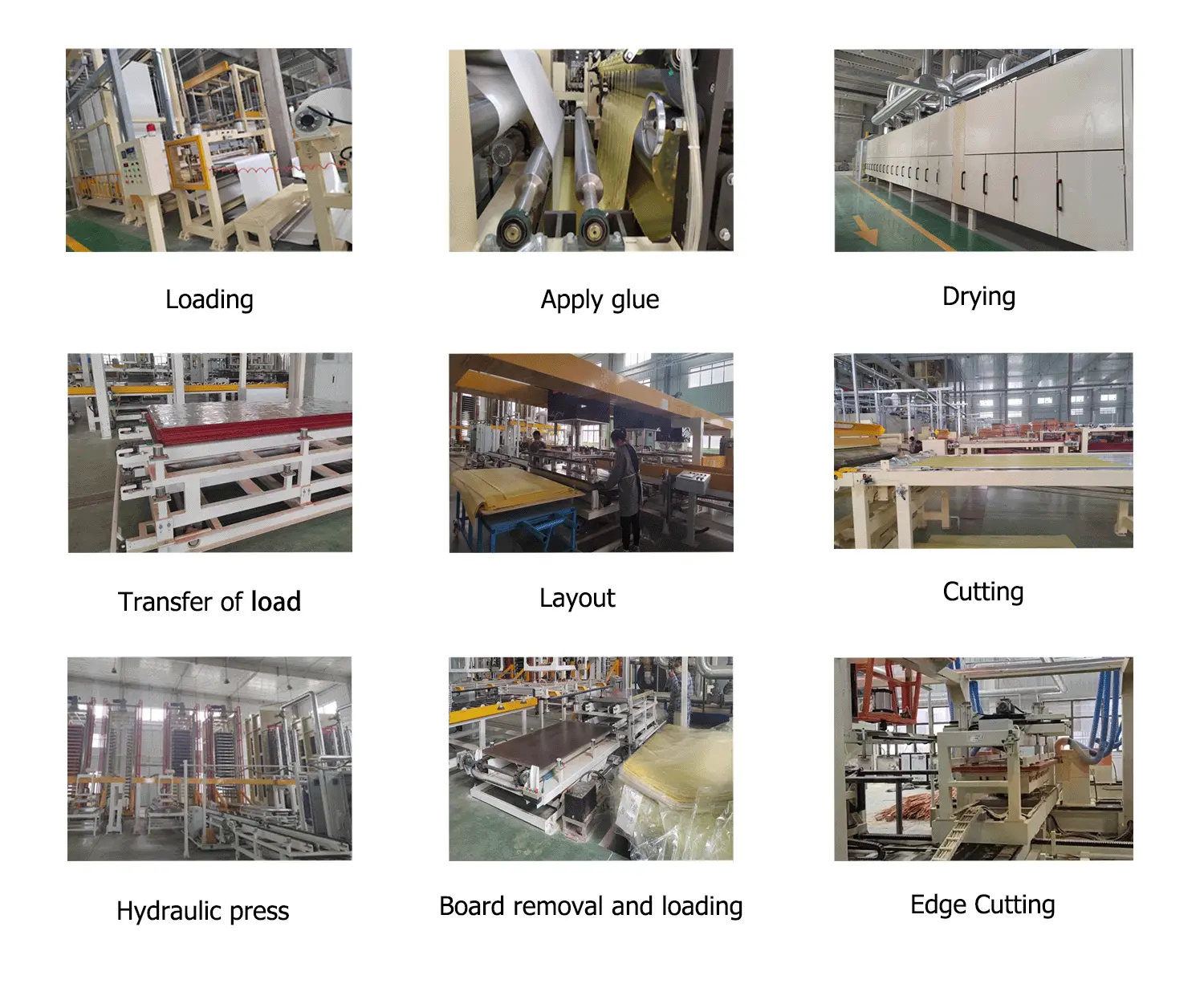

Quality Assurance Process

- Incoming material inspection

- In-process quality monitoring

- Final product testing

- Dimensional verification

- Electrical property validation

Anti-Static Options

While standard sheets give fabulous cover, we offer specialized anti-static variations with resistance values between 5×10⁶–10⁹ ohms for applications requiring electrostatic release protection.

Product Applications

Electrical Industry: Switchgear components, transformer parts, circuit breaker insulation

Electronics Fabricating: PCB substrates, test installations, dances and tooling

Aerospace: Insides boards, basic components, electrical enclosures

Marine Applications: Control boards, electrical boxes, deck hardware

Industrial Gear: Engine cover, generator components, control systems

Automation: Robot components, transport frameworks, security barriers

OEM Service

We get it your interesting prerequisites. Our experienced building group works closely with you to create customized arrangements. From particular measurements to extraordinary fabric properties, we adjust ourproduct to meet your correct specifications.

Custom Services Include:

- Precision machining

- CNC cutting and drilling

- Surface treatments

- Special bundling requirements

- Technical bolster and consultation

Certification

Transportation & Packaging

Packaging: Proficient bed security guarantees secure delivery

Transportation Choices: Sea cargo, arrive transport, discuss cargo

Payment Terms: T/T (Transmitted Transfer)

Frequently Asked Questions

Q: What thicknesses are readily available?

A: We stock thicknesses from 0.3mm to 100mm. Most common thicknesses ship within 3-5 days.

Q: Can you machine the boards to specific shapes?

A: Yes, our machining capabilities include CNC cutting, drilling, and routing to your specifications.

Q: What's the distinction between colors?

A: Color shows distinctive definitions. Light green offers standard properties, whereas yellow and dark variations may have improved characteristics for particular appl

Q: How do I determine the right thickness for my application?

A: Our specialized group can offer assistance you select ideal thickness based on mechanical prerequisites, voltage evaluations, and space constraints.

Q: What's the lead time for custom sizes?

A: Custom dimensions typically require 10-15 working days, depending on specifications and quantity.

Contact Us

Ready to examine your extend necessities? Our specialized specialists are standing by to offer assistance you select the idealize solution.

Email: info@jhd-material.com

Whether you need standard sheets or custom-engineered solutions, we're committed to delivering quality G10 Epoxy Fiberglass Board that surpass your desires. Contact us nowadays for point by point determinations, estimating, or specialized interview.

Send Inquiry

_1764749289736.jpg)

_1764749289159.jpg)