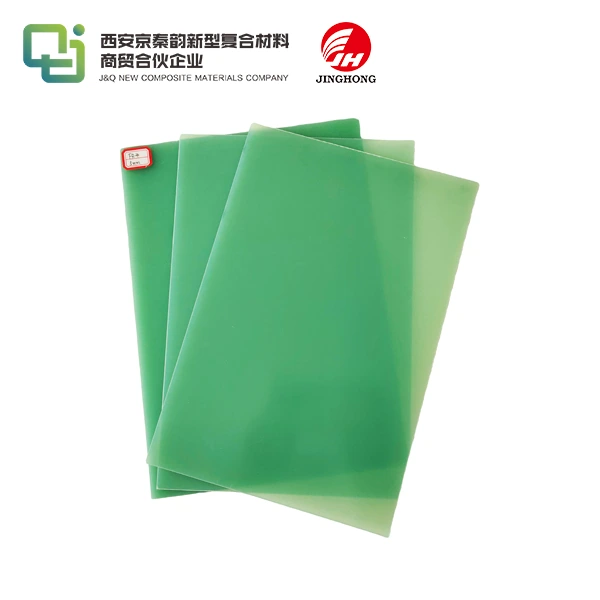

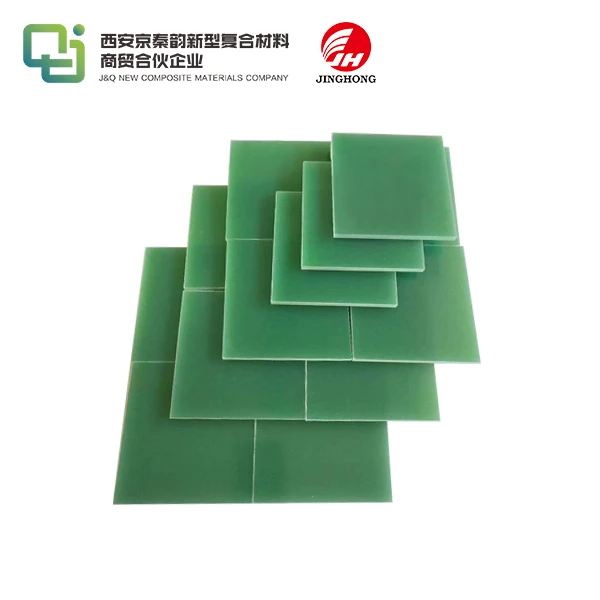

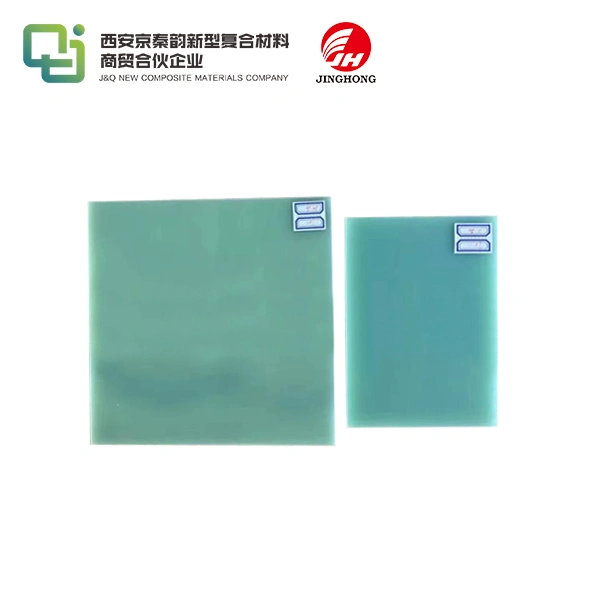

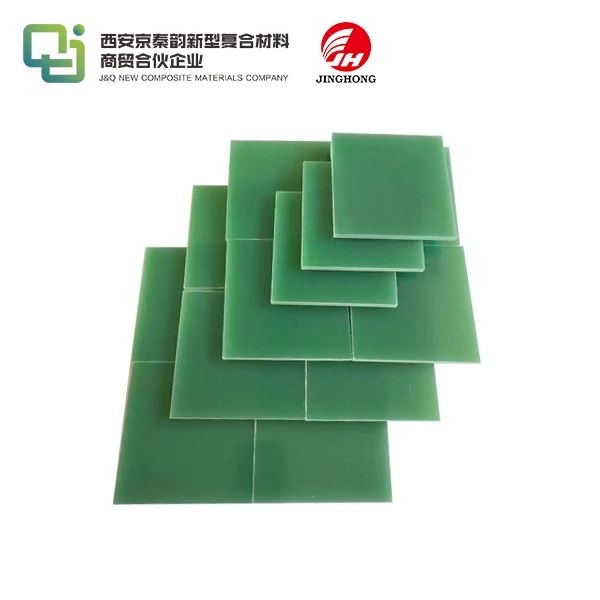

Printed Circuit Board Sheets FR4 Material Fiberglass Epoxy Sheet

G10 FR4 Sheet

Basic Information:

Brand:JingHong

Materials: 7628 Electronic Cloth + Epoxy Resin

Grade: UL94V0,NEMA

Nature Color: Light Green

Thickness: 0.3mm --- 100mm

Regular Size: 1020mm*1220mm,1220mm*2440mm,1020mm*2020mm

Custom Size: 1030mm*2030mm,1030mm*1030mm 1030mm*2070mm

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment:T/T

MOQ:500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

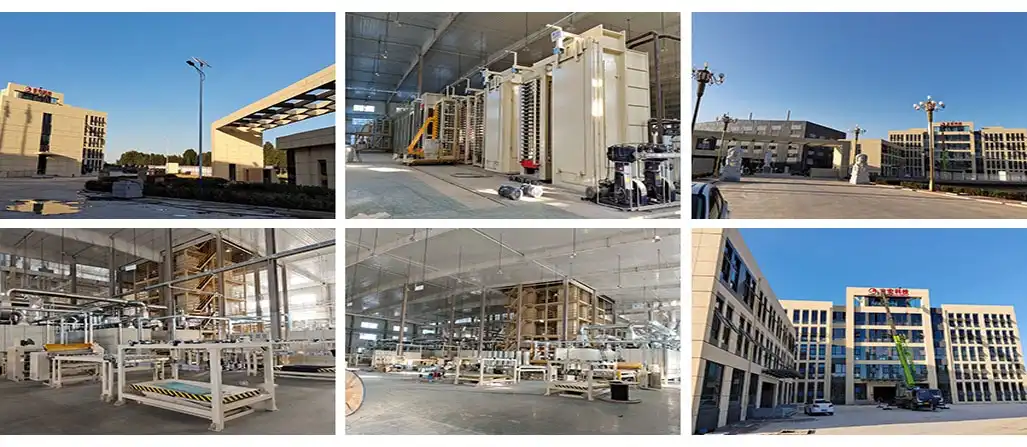

Factory

J&Q New Composite Materials Company is a foreign trade company controlled by Hebei JingHong Electronic Technology Co., Ltd., which is responsible for the export business of Hebei JingHong Electronic Technology Co., Ltd. The new factory of Hebei JingHong Electronics Co., Ltd. will be officially put into production in October 2022. Mainly produce G10 material sheet, 3240 epoxy sheet, Bakelite sheet, and 3026 phenolic cotton sheet. The total annual output of the new and old two factories reaches 43,000 tons, which will be the largest insulation board factory in China.

One of our greatest advantage is the orders which are directly from us has the priority to produce first. Also, we have our own logistics company, so it can provide safe and fast service to you. What we are trying to do is providing our customers one-stop service from production to delivery.

Our strength

1. The annual production capacity of the factory is 43,000 tons, which is one of the largest insulation board manufacturers in China

2. Fully automated production workshop, product quality is stable

3. We have more than 20 years of experience in producing and selling insulating sheet, Cooperate with a number of domestic and foreign trading companies for many years.

4. Professional foreign trade team can provide perfect services

5. Have our own logistics company, provide one-stop service

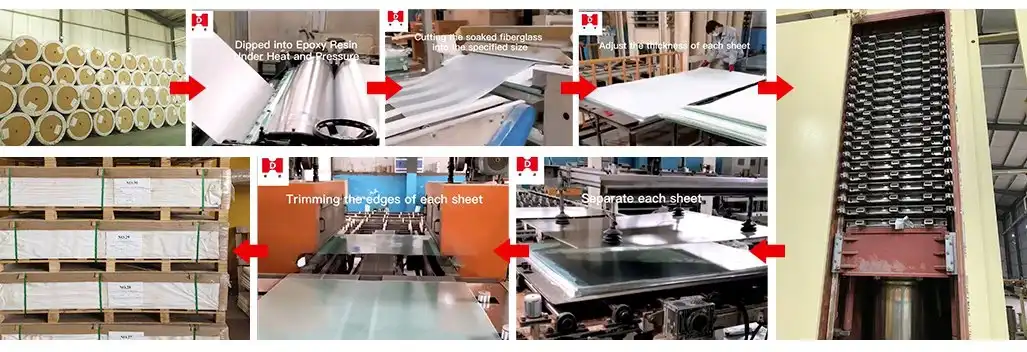

Production Description

G10 material sheet is a composite material that consists of glass fabric, electrical grade epoxy resin. The material is extremely strong and stiff, has a low coefficient of thermal expansion, and outstanding electrical properties. G10/FR-4 is widely used as an insulator for electrical and electronic applications.

The main difference between NEMA Grades G10 and FR4 is that FR4 is a fire retardant grade of G10. Therefore, FR4 may be substituted where G10 is called out except in applications where halogens are not desired. G10 can never be substituted where FR4 is called for.

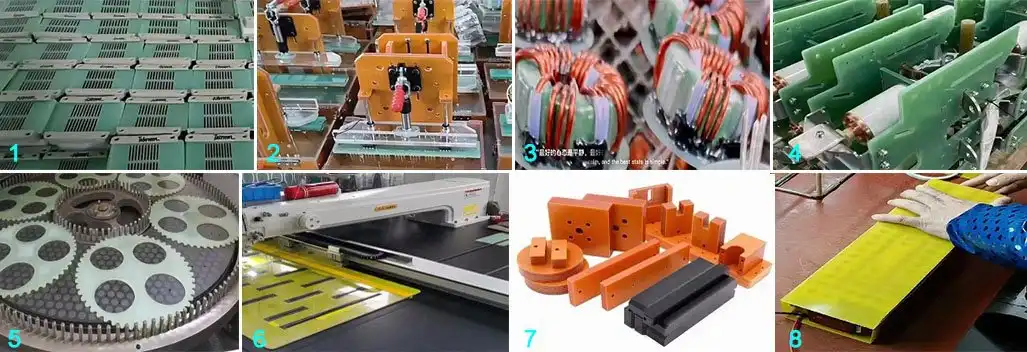

Application

G10 FR4 sheet is used for electrical insulator materials, terminal boards, busebar insulation, electronic test equipment and electric motor rotor insulation. It was first used for printed circuit boards, and its designation

Process

The density of the G10 FR4 sheet is low, the processing of the processing after processing is lightweight. At the same time, the hardness of the sheet is very high. In many cases, G10 materials are used on aviation.

1. Test Jig

2. Fixture PCB Testing Jig

3. Insulation Plate

4. Switch insulation Plate

5. Polish Gear

6. Mould in Cloth and Shoes

7. Insulation Part of Bakelite Sheet

8. Lithium Battery Pack

Punching Machine Process

| G10 FR4 sheet thickness of 0.5mm and 1.5mm are processed by 65tons of punching machine |

| The test result of G10 FR4 sheet after 65 tons of punching machine |

Technical Data for FR4 Sheet

NO | TEST ITEMS | UNIT | TEST RESULT | TEST METHOD |

1 | Bending Strength Perpendicular to Laminations | MPa | 571 | GB/T 1303.4-2009 |

2 | Compressive Strength Perpendicular to Laminations compressive | MPa | 548 | |

3 | Parallel Layer Impact Strength (Simply Supported Beam, Gap) | KJ/m² | 57.3 | |

4 | Tensile Strength | MPa | 282 | |

5 | Vertical Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ25mm/φ75mm cylinder electrode system) | kV/mm | 16.7 | |

6 | Parallel Layer Breakdown Voltage (90℃ + 2℃, 25# transformer oil, 20s step by step boost, φ130mm/φ130mm flat plate electrode system) | kV | >100 | |

7 | Relative Permittivity (50HZ) | - | 5.40 | |

8 | Dielectric Dissipation Factor (50HZ) | 7.2*10-3 | ||

9 | Insulation Resistance after Soaking | Ω | 2.2*1013 | |

10 | Density | g/cm3 | 2.01 | |

11 | Water Absorption | mg | 5.3 | |

12 | Barcol Hardness | - | 76 | GB/T 3854-2005 |

13 | Flammability | Grade | V-0 | GB/T 2408-2008 |

REMARK: 1. NO.2 the sample height is (5.00~5.04) mm; 2. NO.5 the sample thickness is (2.02~2.06) mm; 3. NO.6 the sample size is (100.50~100.52)mm*(25.10~25.15)mm*(5.02~5.06)mm thickness, The electrode spacing is (25.10~25.15)mm; 4. NO.11 the sample size is (49.86~49.90)mm*(49.60~49.63)mm*(2.53~2.65)mm; 5. NO.13 the sample size is (13.04~13.22)mm*(3.04~3.12)mm thickness. | ||||

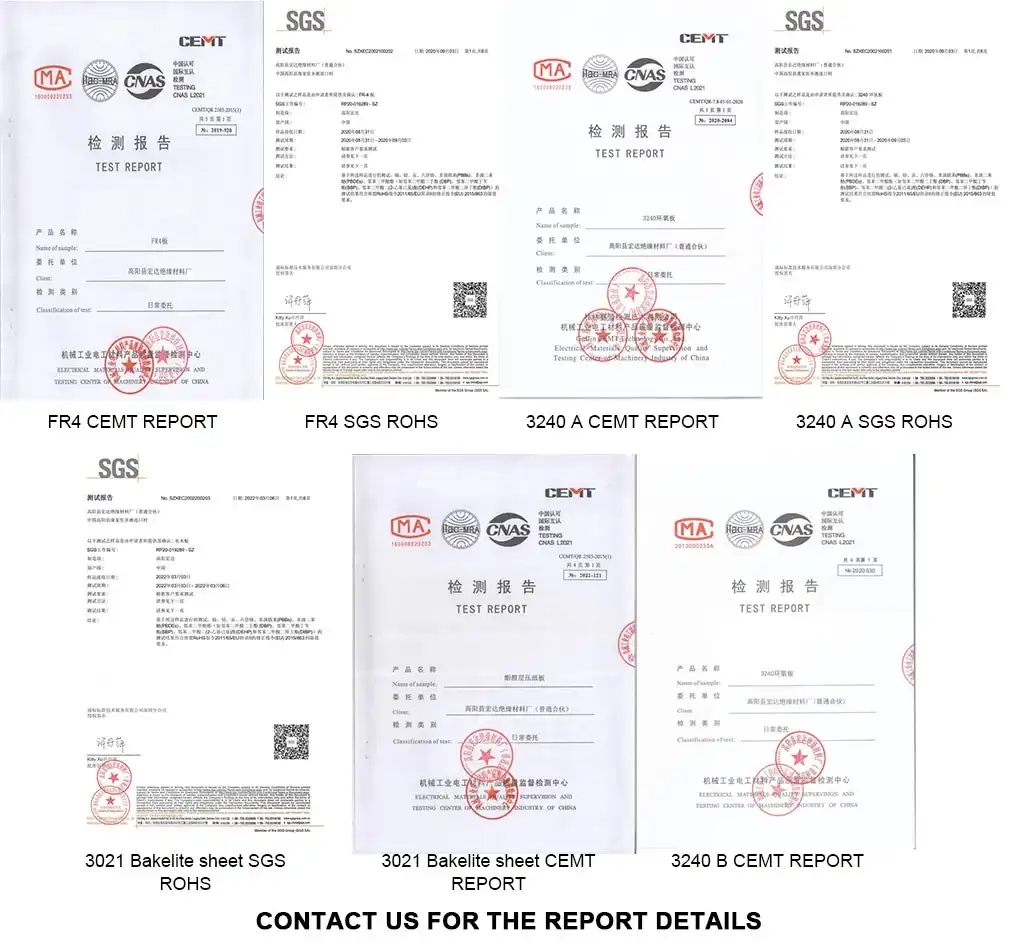

Certification

Production Process

Exhibition

Packaging and Shipping

FAQ

Q: Are you trading company or manufacturer ?

A: We are manufacturer.

Q:What about the package of product?

A:1. Wooden pallet with carton. 2. Plastic pallet with carton. 3. Wooden wooden pallet with wooden case. 4. According to customer requirements.

Q:What's the payment?

A: Payment<=1000USD, 100% in advance

Payment>=1000USD 30%TT advance, 70% TT before shipping

Q:If I need sample,what should I do?

A:It's our pleasure to send sample for you.You can send me your delivery address by email or message.We will send you . . . free sample at first time.

Q:Can you give me a discount price?

A:It is depending on the volume. The larger the volume is; the more discount you can enjoy.

Q:Why is your price a bit higher than other Chinese suppliers?

A:To meet the requirement of different customers and areas, our factory manufactures various kinds of quality for each . . . item at a wide range of price. We can offer the products of different quality levels depending on customer’s target price and quality requirement.

Q:How can you guarantee the quality of mass production is same with the sample sent to me before?

A:Our warehouse staff will leave another same sample in our company, with your company name marked on it, which our production will be based on.

Q:How can you deal with quality issues that customer feedback after receiving the goods?

A:1) Customers take photos of unqualified goods and then our sales staff will send them to Engineering Department to . verify.

2) If the issue is confirmed, our sales staff will explain the root cause and take corrective actions in coming orders.

3) Finally, we will negotiate with our customers to make some compensation.

g10 material for sale

Send Inquiry