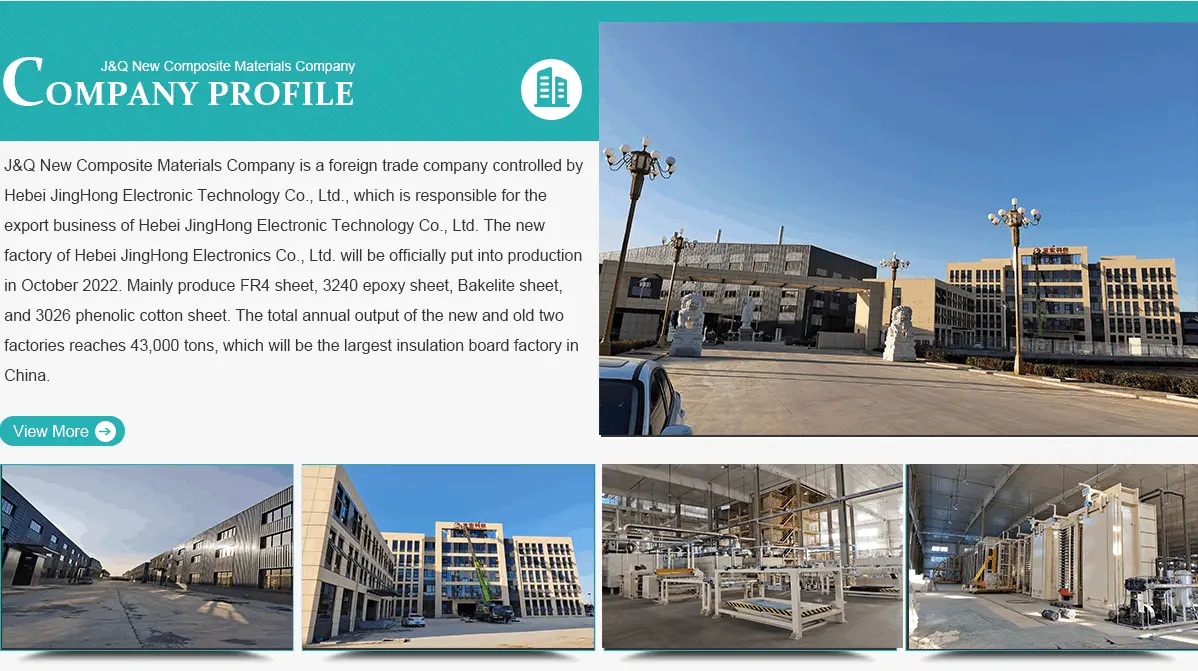

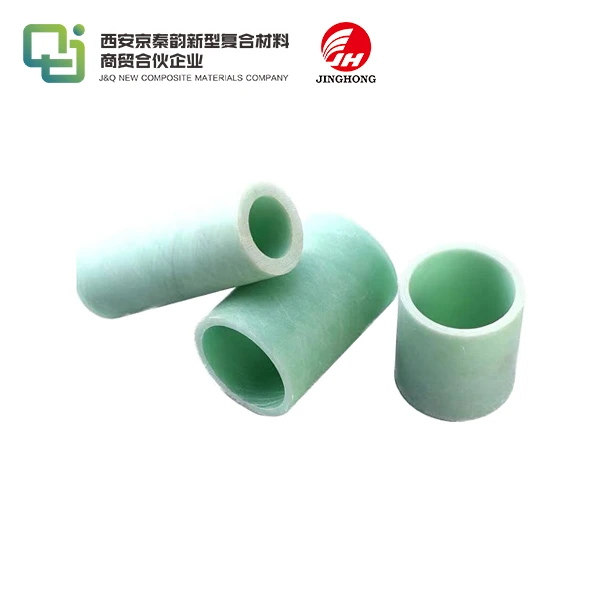

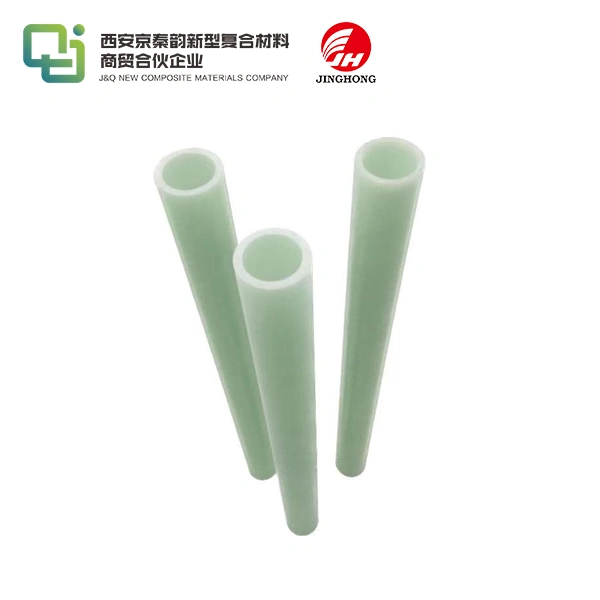

Epoxy Glass Fibre Tube

Basic information:

Brand: Jinghong

Material: Fiberglass + Epoxy Resin

Natural color: Green

Wall thickness: At least 2mm

Custom Size: Inner diameter φ5mm~φ1500mm

Outer diameter φ6mm~φ2000mm

The longest tube length is 2m

Packaging: Regular packaging

Production capacity: 100 tons per year

Transportation: ocean, land, air

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Epoxy Glass Fibre Tube - High-Performance Insulation Solutions

Our Epoxy Glass Fibre Tube combines prevalent execution with extraordinary strength. This premium cover arrangement highlights progressed fiberglass development fortified with high-grade epoxy gum. You'll get steady assurance for your electrical frameworks. The particular green wrap up gives simple recognizable proof in complex establishments. Our fabricating mastery guarantees each tube meets strict quality measures. Whether you require standard sizes or custom measurements, we provide arrangements that perform when it things most.

Product Description

J&Q Unused Composite Fabric Bunch brings you industry-leading cover tubes beneath our trusted Jinghong brand. Each tube combines carefully chosen fiberglass support with premium epoxy tar network. This combination conveys exceptional electrical properties and mechanical strength.

You'll appreciate the normal green coloration that makes recognizable proof straightforward amid establishment and support. The smooth surface wrap up guarantees simple dealing with whereas giving fabulous chemical resistance.

Product Availability

We keep up comprehensive stock to meet your venture timelines. Our generation office works year-round with a capacity of 100 tons every year. Standard sizes dispatch inside 5-7 trade days. Custom details require 2-3 weeks for fabricating and quality verification.

Global shipping alternatives incorporate sea cargo for huge orders, sped up discuss transport for pressing needs, and solid ground transportation for territorial deliveries.

Key Features

Superior Electrical Properties

- Excellent dielectric strength

- Low dampness absorption

- Consistent separator resistance

Mechanical Excellence

- High ductile strength

- Impact resistance

- Dimensional solidness over temperature ranges

Chemical Resistance

- Resistant to oils and solvents

- UV steady formulation

- Long-term natural durability

Customization Options

- Inner distances across from φ5mm to φ1500mm

- Outer breadths from φ6mm to φ2000mm

- Maximum length up to 2 meters

- Minimum divider thickness of 2mm for basic integrity

Standards

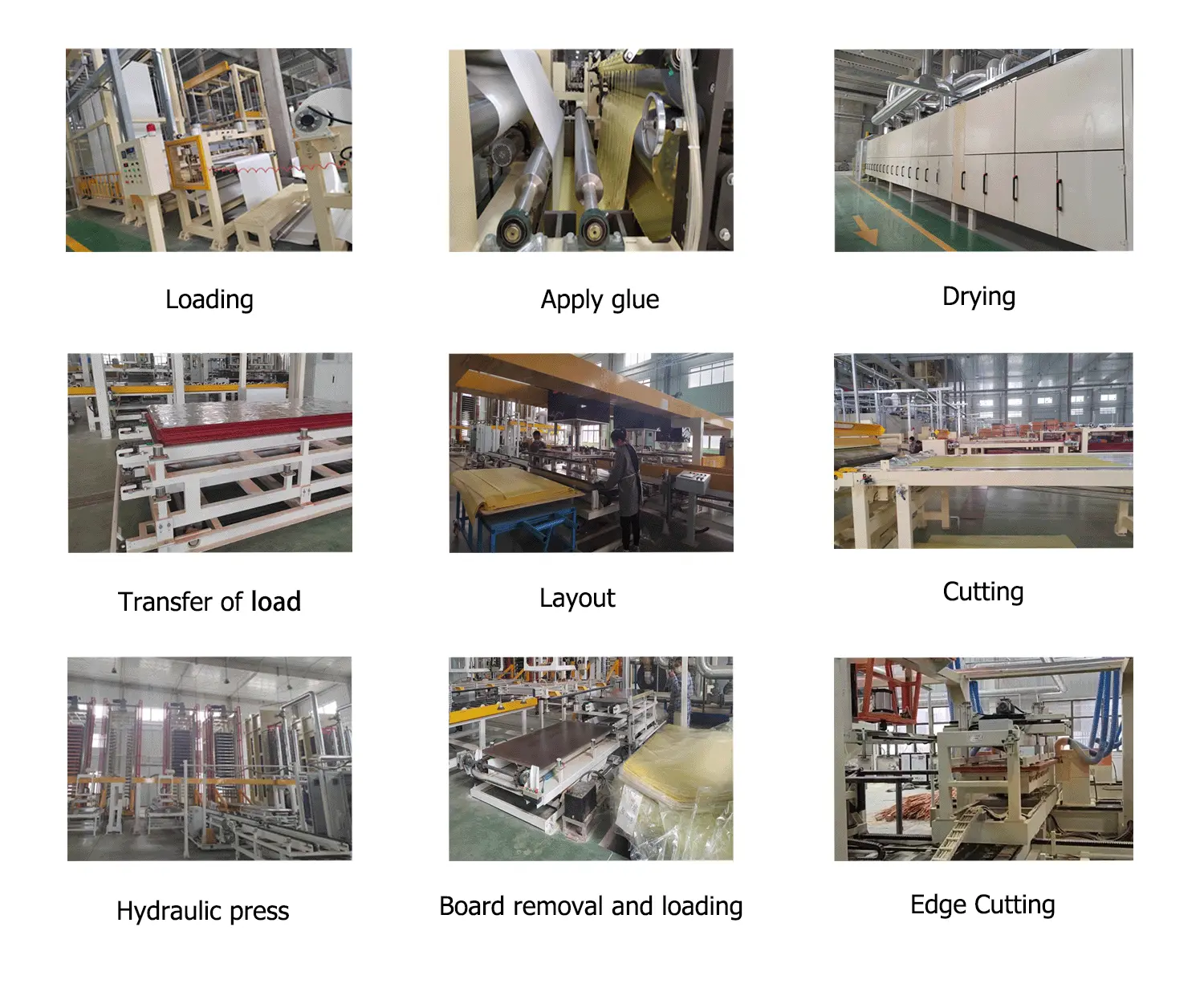

Our fabricating forms adjust with universal quality benchmarks. Each generation group experiences thorough testing for electrical properties, dimensional exactness, and fabric consistency. We keep up nitty gritty quality records for full traceability.

Technical Features: Product Safety Control

Density Specifications

Material thickness ranges from 1.65 to 1.80 g/cm³, guaranteeing ideal adjust between quality and weight.

Quality Assurance Process

- Incoming crude fabric inspection

- In-process checking of tar cure

- Dimensional confirmation utilizing accuracy measurement

- Electrical property testing per batch

- Visual review for surface defects

Environmental Testing

Each item arrangement experiences quickened maturing tests to confirm long-term execution beneath different natural conditions.

Product Application

Electrical Industry

Perfect for transformer bushings, engine windings security, and switchgear cover. The Epoxy Glass Fibre Tube gives dependable boundary security in high-voltage applications.

Electronics Manufacturing

Ideal for component lodging, cable administration, and circuit board standoffs. You'll discover these tubes basic for keeping up appropriate dispersing and insulation.

Industrial Equipment

Excellent for pump shaft assurance, bearing confinement, and apparatus component partition. The chemical resistance makes them appropriate for cruel mechanical environments.

Renewable Energy

Wind turbine components and sun powered board mounting frameworks advantage from the weather-resistant properties and mechanical strength.

OEM Service

We accomplice with you to create custom arrangements that coordinate your correct determinations. Our building group works closely with your architects to optimize execution and cost-effectiveness.

Design Support

- Material choice guidance

- Performance optimization recommendations

- Prototype advancement and testing

Manufacturing Flexibility

- Small bunch custom runs

- Volume generation capabilities

- Consistent quality over all arrange sizes

Your determinations drive our fabricating prepare. We adjust our generation strategies to provide precisely what your application requires.

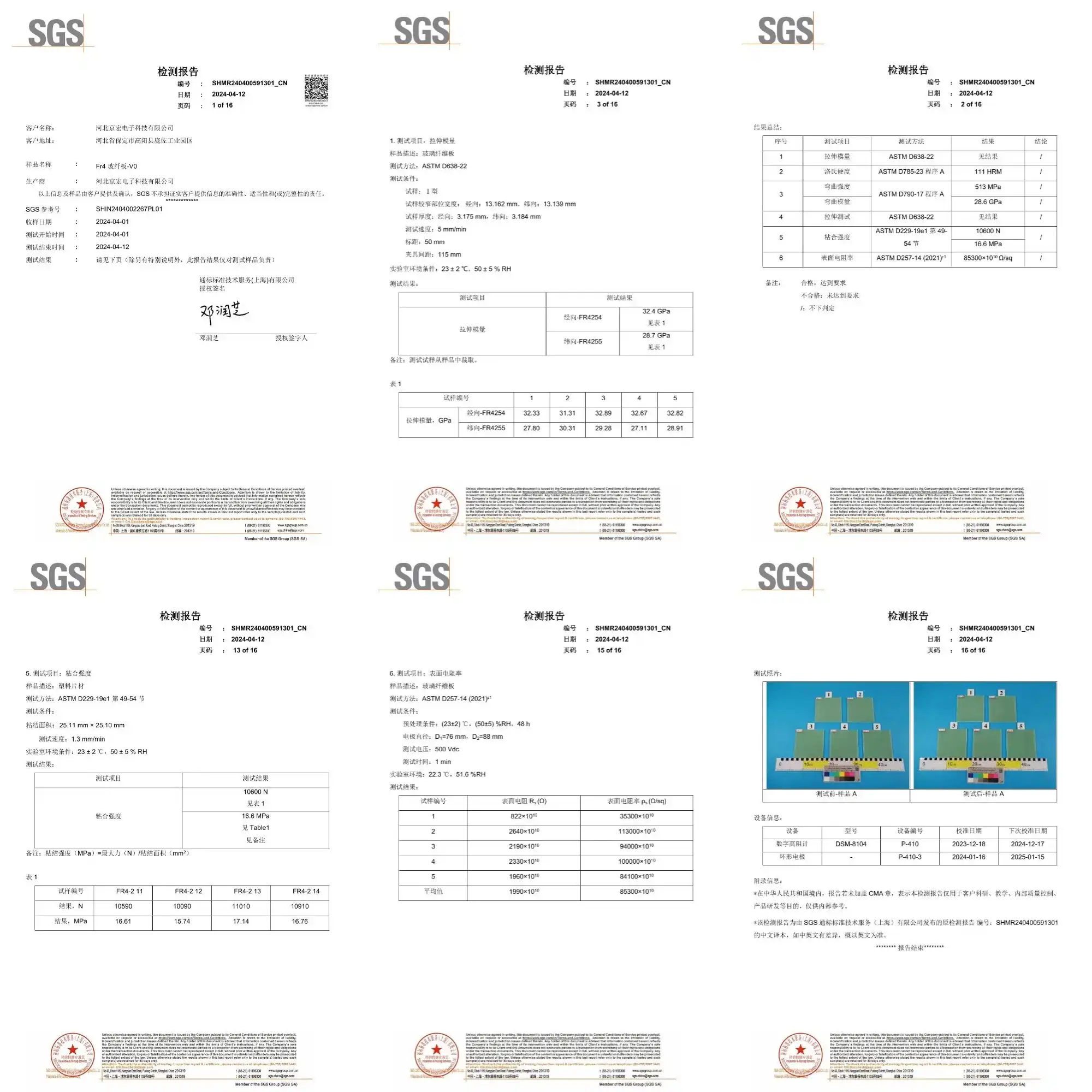

Certification

FAQ

Q: Can these tubes be customized?

A: Yes, we offer total customization in sizes, thicknesses, and lengths to meet your particular venture requirements.

Q: What is the material density?

A: The thickness ranges from 1.65 to 1.80 g/cm³, giving great strength-to-weight characteristics.

Q: Can this insulating tube be customized in other colors?

A: Our product comes in normal light green color by default, with a few color variety conceivable depending on distance across requirements.

Q: What are the temperature limits?

A: These tubes perform dependably in standard mechanical temperature ranges. Contact us for particular temperature requirements.

Q: How do you ensure consistent quality?

A: Each group experiences comprehensive testing counting electrical properties, dimensional exactness, and visual review some time recently shipment.

Contact Us

Ready to discuss your insulation needs? Our technical team stands ready to help you select the right Epoxy Glass Fibre Tube for your application.

Email us at info@jhd-material.com for detailed specifications, custom quotes, or technical support. We respond to all inquiries within 24 hours and provide comprehensive technical documentation with every quote.

Send Inquiry

_1747991245292.webp)

_1753952475136.jpg)