2025 Market Trends for FR4 Epoxy Fiberglass Sheet

2025-08-08 16:23:25

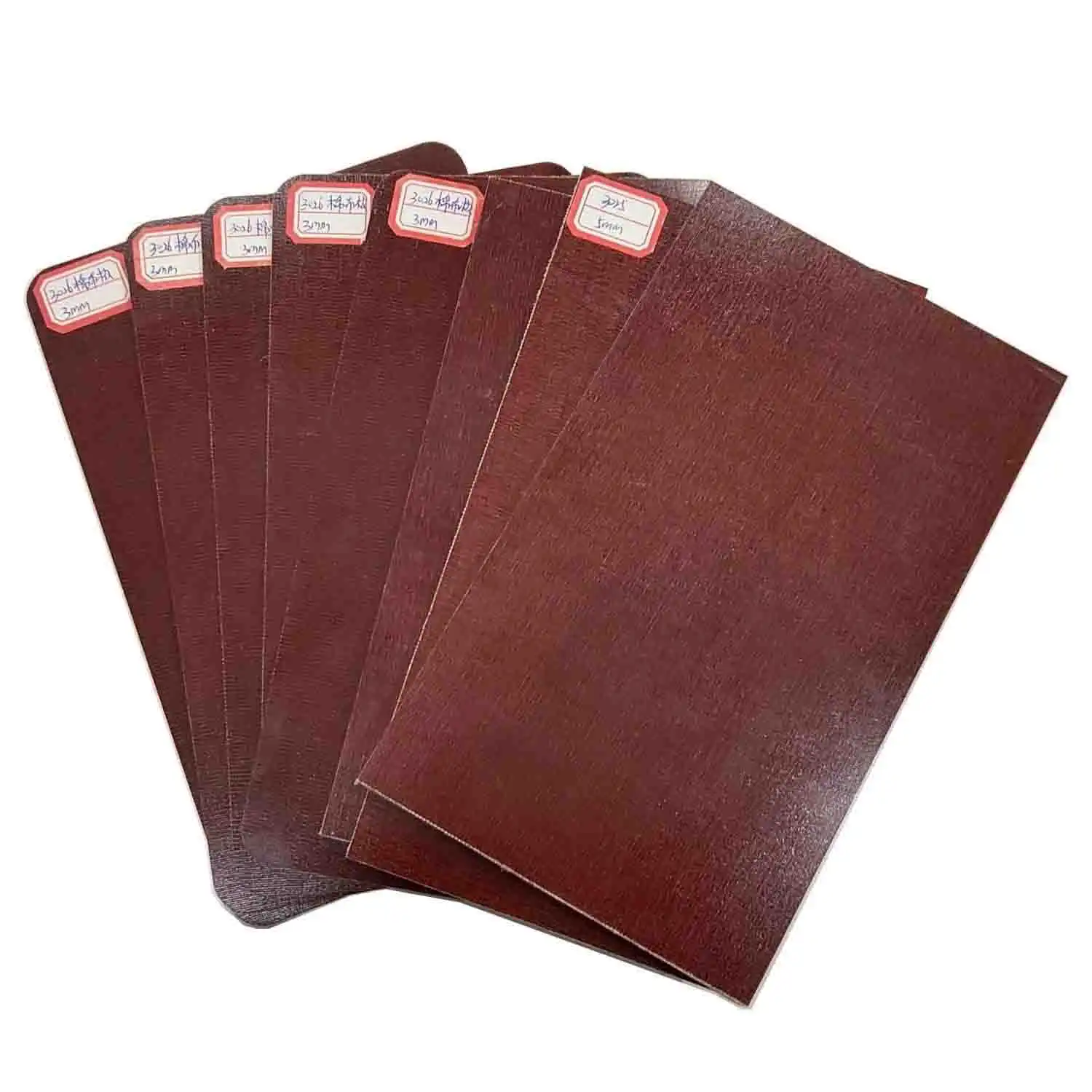

As we move through 2025, the market for FR4 epoxy fiberglass sheet is experiencing robust growth, fueled by surging demand in electronics, renewables, and automotive sectors. This versatile insulating material, known for its flame-retardant properties and mechanical strength, is seeing a compound annual growth rate of around 8% globally, according to industry forecasts. Key trends include a shift toward sustainable, halogen-free variants to meet environmental regulations, integration with high-frequency applications like 5G infrastructure, and enhanced thermal management for electric vehicles. Manufacturers are innovating to reduce costs while improving performance, amid ongoing supply chain optimizations following global disruptions. For businesses relying on reliable insulation, these developments signal opportunities for efficiency gains and expanded applications, making FR4 a cornerstone in advancing technologies. With our two decades of expertise at J&Q, we're witnessing this evolution firsthand, helping clients navigate these shifts seamlessly.

Emerging Applications Driving Demand for FR4 Epoxy Fiberglass Sheet

The landscape for FR4 epoxy fiberglass sheet is expanding rapidly as new industries recognize its value in providing durable, heat-resistant insulation. This material, often used as a base for printed circuit boards, is finding fresh roles that align with global tech advancements. Let's explore some key areas where demand is currently surging.

Electronics and IoT Integration

In the realm of consumer gadgets and smart devices, FR4 epoxy fiberglass sheet continues to stand out for its ability to support intricate circuitry without compromising on safety. As Internet of Things (IoT) devices proliferate - from smart homes to wearable tech - the need for compact, reliable substrates grows. The production of FR4 materials has scaled up to accommodate billions of connected devices in circulation this year, where FR4's epoxy composite structure ensures signal integrity and resistance to environmental stressors. We've seen clients in this space benefit from its low dielectric constant, which minimizes signal loss in high-density designs. This trend reflects not just volume growth, but the drive to enable sleeker, more efficient consumer technologies.

Renewable Energy Sector Growth

Solar panels and wind turbines are pushing the boundaries of energy production, and FR4 epoxy fiberglass sheet plays a crucial role in their electrical insulation needs. Its fiberglass-reinforced epoxy makeup withstands harsh outdoor conditions, making it ideal for photovoltaic modules and inverter systems. With global commitments to net-zero emissions well underway, the renewable sector has driven a notable increase in FR4 demand. Manufacturers are now deploying laminates with enhanced UV resistance, which extend component lifespan in renewable infrastructure. At J&Q, our long-standing partnerships have shown how this material contributes to more resilient green technology, helping clients meet sustainability targets while maintaining high performance.

Automotive and Electric Vehicle Advancements

Electric vehicles (EVs) continue to reshape transportation in 2025, and FR4 epoxy fiberglass sheet is critical to their power systems. Used in battery management and charging components, it provides essential thermal and electrical isolation. With EVs now representing approximately 30% of global new car sales, demand for high-grade insulating sheets is soaring, especially those with superior flame retardancy. This shift is also driving interest in lightweight, high-performance FR4 variants that improve vehicle efficiency. Our export experience with leading automotive OEMs confirms that FR4's robust performance supports safer, longer-range electric mobility solutions.

Technological Advancements Shaping FR4 Epoxy Fiberglass Sheet

Innovation is the lifeblood of the FR4 epoxy fiberglass sheet industry, with ongoing R\&D aimed at performance upgrades to meet the challenges of 2025 and beyond. These advancements are transformative, addressing long-standing issues like thermal management and sustainability. Here's what's shaping the landscape today.

Enhanced Thermal Management Features

Heat buildup remains a core concern in dense electronic assemblies, but newer formulations of FR4 epoxy fiberglass sheet are addressing it effectively. By incorporating fillers to increase thermal conductivity, these sheets now dissipate heat more efficiently - critical for data centers and high-power electronics. Thermally optimized FR4 variants are now capturing significant market share, driven by the growing needs of edge computing environments. Thanks to our two decades of technical expertise, J&Q continues to deliver thermally stable FR4 products that retain structural integrity under continuous heat exposure, reducing failure rates and extending component lifespans.

Eco-Friendly and Halogen-Free Variants

Sustainability is now a fundamental market driver. Halogen-free FR4 variants, which eliminate brominated compounds, have become a market standard in response to global environmental regulations such as RoHS and REACH. These greener alternatives are gaining traction rapidly in 2025, especially among OEMs focused on ESG compliance. Innovations such as bio-based resins are emerging, preserving FR4's mechanical strength while lowering environmental impact. At J&Q, we collaborate with global clients to meet green compliance needs while maintaining product performance, helping customers align with both legal requirements and consumer expectations.

High-Frequency and Dielectric Improvements

As 5G networks continue to scale in 2025, FR4 epoxy fiberglass sheet is being tailored for high-frequency applications that demand superior dielectric performance. Improved glass cloth laminates are enabling low-loss designs essential for radar systems and millimeter-wave communication. The telecom sector is seeing consistent annual growth in this segment, fueled by rapid deployment of next-gen networks. At J&Q, we support clients with advanced sheet materials that ensure reliable signal performance, helping them reduce design complexity while maximizing speed and efficiency.

Global Market Dynamics and Challenges for FR4 Epoxy Fiberglass Sheet

Navigating the FR4 epoxy fiberglass sheet market in 2025 requires more than product innovation - it demands an understanding of the broader geopolitical and economic environment. Let's explore the current market forces at play.

Supply Chain Optimizations and Regional Shifts

In the post-pandemic landscape, global supply chains are evolving toward diversification and risk mitigation. While Asia-Pacific remains a production powerhouse, North America and Europe are expanding local manufacturing capabilities to reduce reliance on foreign supply. These regional shifts are helping to stabilize FR4 pricing amid continued volatility in raw material costs. At J&Q, our global logistics partnerships and digital inventory tracking ensure uninterrupted supply, giving our customers peace of mind in uncertain times.

Regulatory and Compliance Evolutions

Environmental and safety regulations have intensified in 2025, compelling FR4 manufacturers to adopt cleaner, safer production methods. This includes reduced VOC emissions in resin formulation and full compliance with international certifications. While compliance measures may marginally increase production costs, they also offer competitive advantages in high-value markets. At J&Q, we work closely with clients to deliver fully compliant, certified products that meet global standards - from CE to UL - opening doors to broader export and procurement opportunities.

Competitive Landscape and Pricing Pressures

Competition remains fierce in the FR4 epoxy fiberglass sheet market, especially as manufacturers from emerging markets introduce low-cost alternatives. However, price alone is not enough to win. Customers are demanding more - including technical support, customization, and sustainable sourcing. With the market valued at \$2.8 billion in 2025, differentiation is key. J&Q leverages deep manufacturing experience to deliver tailored FR4 solutions, balancing performance, compliance, and cost-effectiveness for global clients across high-demand sectors.

Conclusion

As we progress through 2025, the FR4 epoxy fiberglass sheet market is thriving thanks to innovation, sustainability, and expanding high-tech applications. From supporting 5G networks to driving EV safety and efficiency, this material continues to prove its value. While market dynamics present challenges, they also unlock new opportunities for those ready to adapt. With over 20 years of expertise, J&Q stands at the forefront of these changes, delivering FR4 products that meet the evolving needs of our global partners.

Contact Us

Ready to explore how FR4 epoxy fiberglass sheet can elevate your projects? Reach out to us at info@jhd-material.com for personalized insights and competitive quotes.

References

1. Global FR4 Market Analysis Report 2023-2028, MarketsandMarkets

2. Insulating Materials in Electronics: Trends and Forecasts, IDTechEx Research

3. Advanced Composites Market Outlook to 2025, Grand View Research

4. Epoxy Resin Market Trends and Opportunities, Mordor Intelligence

5. Printed Circuit Board Materials: Future Directions, IPC International

6. Sustainable Laminates in Renewable Energy Applications, Frost & Sullivan