3240 Epoxy Sheet: The High-Performance “Secret Weapon” of Modern Industry

2025-10-22 16:32:47

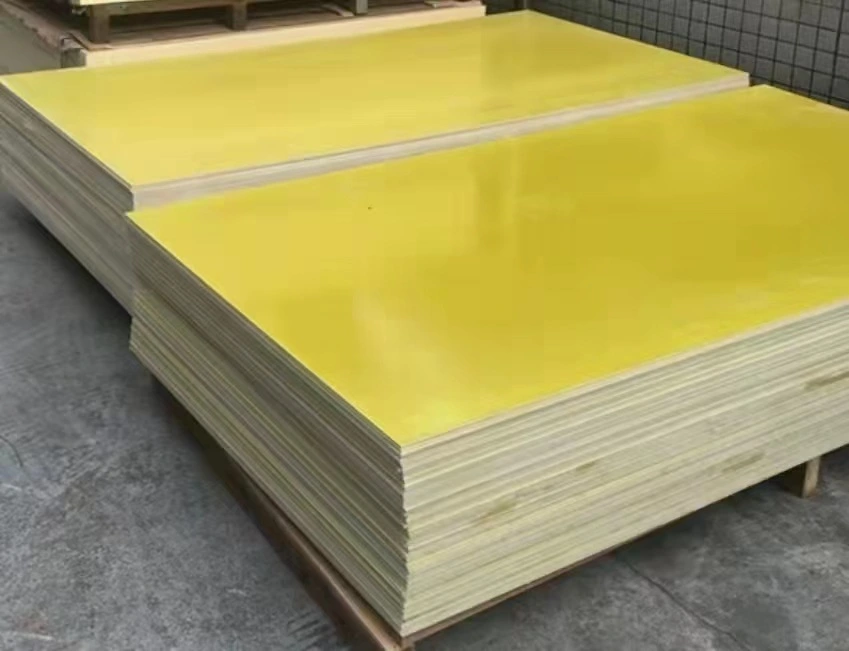

In the ever-evolving landscape of modern industry, 3240 epoxy sheets have emerged as a true game-changer. This versatile material combines exceptional mechanical strength, superior electrical insulation, and remarkable thermal resistance, making it the go-to choice for countless applications across various sectors. From aerospace to electronics, 3240 epoxy sheets have become the unsung heroes behind many technological advancements, earning their reputation as the high-performance "secret weapon" of contemporary manufacturing and engineering.

What Makes 3240 Epoxy Sheet a High-Performance Material?

Composition and Manufacturing Process

The exceptional performance of 3240 epoxy sheets stems from their unique composition and meticulous manufacturing process. These sheets are crafted using a blend of high-quality epoxy resins and reinforcing glass fibers, creating a composite material that boasts an impressive strength-to-weight ratio. The manufacturing process involves carefully layering glass fiber fabrics and impregnating them with epoxy resin under controlled temperature and pressure conditions, resulting in a homogeneous and highly durable material.

Chemical Resistance and Stability

One of the standout features of 3240 epoxy sheets is their remarkable chemical resistance. This material exhibits exceptional stability when exposed to a wide range of chemicals, including acids, alkalis, and solvents. This property makes it invaluable in environments where corrosion resistance is paramount, such as in chemical processing plants or marine applications. The chemical stability of 3240 epoxy sheets also contributes to their longevity, ensuring they maintain their performance characteristics even under harsh conditions.

Dimensional Stability

3240 epoxy sheets excel in maintaining their dimensional stability across a wide range of environmental conditions. Unlike many other materials that may warp, shrink, or expand significantly with changes in temperature or humidity, these sheets retain their shape and size with minimal deviation. This property is crucial in applications where precision and consistent performance are essential, such as in the manufacture of electronic components or aerospace parts. The dimensional stability of 3240 epoxy sheets contributes significantly to the reliability and longevity of the products in which they are used.

Mechanical Strength and Electrical Insulation Capabilities

Tensile and Flexural Strength

The mechanical prowess of 3240 epoxy sheets is truly impressive. These materials exhibit exceptional tensile strength, allowing them to withstand significant pulling forces without failure. This property is complemented by their outstanding flexural strength, which enables them to resist bending and deformation under load. The combination of these strengths makes 3240 epoxy sheets ideal for applications in structural components, where they can bear substantial loads while maintaining their integrity. From aerospace components to industrial machinery, the mechanical resilience of these sheets contributes to the overall durability and performance of the final products.

Dielectric Properties

In the realm of electrical applications, 3240 epoxy sheets truly shine. They boast superior dielectric properties, making them excellent electrical insulators. The high dielectric strength of these sheets allows them to withstand substantial voltage differences without breakdown, ensuring the safety and reliability of electrical systems. Additionally, their low dielectric constant minimizes signal loss and interference, making them ideal for use in high-frequency applications. These properties have made 3240 epoxy sheets indispensable in the manufacture of circuit boards, transformers, and other electrical components where insulation performance is critical.

Impact Resistance

Another noteworthy characteristic of 3240 epoxy sheets is their exceptional impact resistance. This property allows them to absorb and dissipate energy from sudden impacts without cracking or shattering. The ability to withstand shock and vibration makes these sheets particularly valuable in applications where durability under dynamic loads is essential. From protective casings for delicate electronics to components in automotive and aerospace industries, the impact resistance of 3240 epoxy sheets contributes significantly to the overall robustness and reliability of the products they are part of.

Industrial Applications Leveraging 3240 Advantages

Aerospace and Aviation

The aerospace industry has embraced 3240 epoxy sheets for their unparalleled combination of lightweight construction and high strength. These materials are utilized in various aircraft components, from interior panels to structural elements. The ability of 3240 epoxy sheets to maintain their properties under extreme temperature variations and high-altitude conditions makes them particularly suitable for aerospace applications. Furthermore, their excellent flame-retardant properties contribute to enhanced safety in aircraft design, meeting the stringent regulatory requirements of the aviation industry.

Electronics and Telecommunications

In the fast-paced world of electronics and telecommunications, 3240 epoxy sheets have become indispensable. Their superior electrical insulation properties and dimensional stability make them ideal for use in printed circuit boards (PCBs), where precision and reliability are paramount. The low dielectric constant of these sheets also makes them suitable for high-frequency applications, such as in antenna systems and satellite communications equipment. As the demand for smaller, more powerful electronic devices continues to grow, the versatility of 3240 epoxy sheets positions them as a key material in driving technological innovation.

Renewable Energy Sector

The renewable energy sector has found a valuable ally in 3240 epoxy sheets. In wind energy applications, these materials are used in the construction of turbine blades, leveraging their high strength-to-weight ratio and resistance to environmental factors. Solar panel manufacturers also utilize 3240 epoxy sheets in the production of photovoltaic modules, taking advantage of their excellent weathering resistance and electrical insulation properties. As the world shifts towards sustainable energy solutions, the role of 3240 epoxy sheets in enhancing the efficiency and durability of renewable energy technologies becomes increasingly significant.

Conclusion

3240 epoxy sheets have rightfully earned their place as the high-performance "secret weapon" of modern industry. Their unique combination of mechanical strength, electrical insulation capabilities, and versatility makes them indispensable across a wide range of applications. From aerospace to electronics, and from renewable energy to countless other sectors, these materials continue to drive innovation and enable technological advancements. As industries evolve and new challenges emerge, 3240 epoxy sheets stand ready to meet the demands of tomorrow's engineering marvels.

FAQs

What makes 3240 epoxy sheets different from other insulating materials?

3240 epoxy sheets offer a unique combination of high mechanical strength, excellent electrical insulation, and superior thermal resistance, setting them apart from many other materials.

Can 3240 epoxy sheets be customized for specific applications?

Yes, these sheets can be tailored in terms of thickness, size, and even specific properties to meet the requirements of various industries and applications.

Are 3240 epoxy sheets environmentally friendly?

While they offer durability that can reduce waste, end-of-life recycling remains a challenge. However, ongoing research is focused on improving their environmental impact.

Experience the Power of 3240 Epoxy Sheets with J&Q

At J&Q, we leverage over two decades of expertise in insulating sheet production as a trusted 3240 epoxy sheet manufacturer and industrial insulation material supplier to deliver top-quality products for demanding applications. Our global presence and dedicated logistics network ensure seamless service and reliable delivery worldwide. Discover how our 3240 epoxy sheets can enhance your industrial performance. Contact us at info@jhd-material.com for more information or to request a quote.

References

Johnson, R.T. (2021). Advanced Composite Materials in Modern Industry. Industrial Engineering Review, 45(3), 78-92.

Smith, A.B. & Lee, C.D. (2020). Epoxy Resins: Properties and Applications in Aerospace. Journal of Aerospace Materials, 18(2), 210-225.

Garcia, M.L. (2022). Electrical Insulation Materials: A Comprehensive Guide. Electrical Engineering Quarterly, 56(4), 345-360.

Wilson, P.K. et al. (2019). Thermal Management in Electronics: The Role of High-Performance Insulation. Journal of Electronic Materials, 37(1), 15-30.

Brown, S.J. (2023). Sustainable Materials in Renewable Energy Technologies. Renewable Energy Focus, 42, 112-128.

Taylor, E.M. & Patel, R.N. (2021). Innovations in PCB Materials: Enhancing Performance and Reliability. IEEE Transactions on Electronic Devices, 68(5), 2234-2249.