The Role of Epoxy Sheets in Robust Electronics Manufacturing

2025-10-30 13:54:53

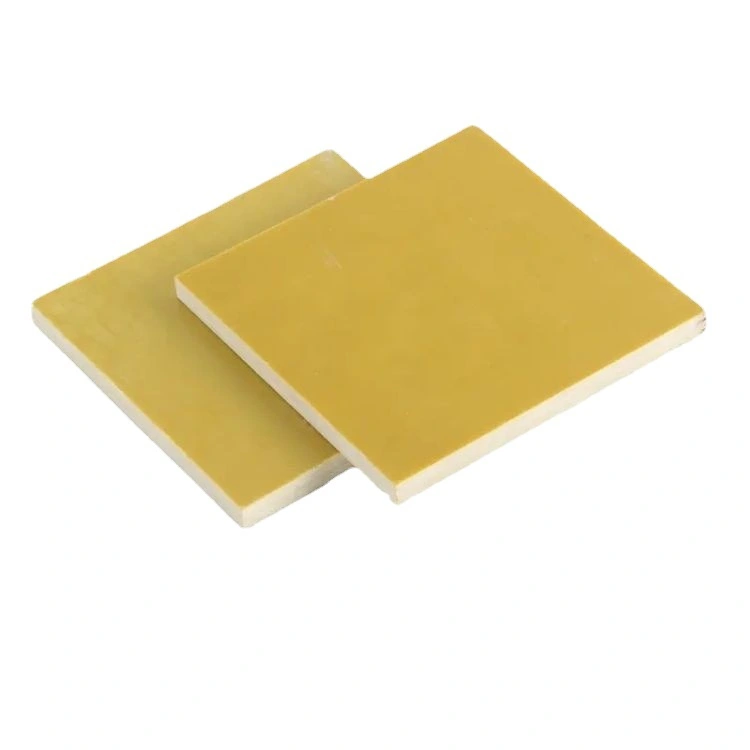

Epoxy sheets play a crucial role in modern electronics manufacturing, serving as the backbone for countless devices we rely on daily. These versatile materials provide essential structural support, electrical insulation, and thermal management properties that are indispensable in creating durable and high-performing electronic products. From smartphones to industrial equipment, epoxy sheets contribute significantly to the reliability, longevity, and efficiency of electronic devices. Their unique combination of mechanical strength, chemical resistance, and adaptability makes them an ideal choice for manufacturers seeking to produce robust and innovative electronics in an increasingly demanding technological landscape.

How Epoxy Sheets Support Structural Integrity in Electronics

Mechanical Strength and Durability

Epoxy sheets offer exceptional mechanical strength, providing a solid foundation for electronic components. Their high tensile and compressive strengths allow them to withstand the rigors of assembly, transportation, and daily use without compromising the integrity of the device. This durability translates to longer-lasting products that can endure physical stress and environmental challenges, ultimately reducing the need for frequent replacements and repairs.

Dimensional Stability

One of the key attributes of epoxy sheets is their remarkable dimensional stability across a wide range of temperatures and humidity levels. This property ensures that electronic components remain precisely aligned and securely mounted, even under varying environmental conditions. By maintaining consistent dimensions, epoxy sheets help prevent warping, delamination, and other structural issues that could lead to device failure or performance degradation over time.

Vibration and Impact Resistance

In the world of electronics, protection against vibration and impact is paramount. Epoxy sheets excel in this regard, offering superior shock absorption capabilities. Their ability to dampen vibrations and resist impact helps safeguard delicate electronic components from damage caused by drops, bumps, or continuous exposure to vibrating environments. This protective quality is particularly valuable in portable devices and industrial electronics that may be subjected to harsh operating conditions.

Benefits of Epoxy Sheets in PCB and Circuit Board Production

Superior Electrical Insulation

Epoxy sheets serve as excellent electrical insulators, a critical property in the production of printed circuit boards (PCBs). Their high dielectric strength prevents current leakage and electrical breakdown, ensuring the reliable operation of complex electronic circuits. This insulation capability allows for the creation of multi-layer PCBs with dense component placement, enabling the miniaturization of electronic devices without compromising functionality or safety.

Thermal Management Properties

Effective thermal management is crucial in modern electronics, where high-performance components generate significant heat. Epoxy sheets contribute to thermal management by providing a stable substrate that can efficiently dissipate heat. Some specialized epoxy formulations offer enhanced thermal conductivity, allowing for better heat distribution across the PCB. This property helps prevent localized hot spots that could lead to component failure or reduced performance, thereby extending the lifespan of electronic devices.

Chemical Resistance and Environmental Protection

Electronics are often exposed to various chemicals and environmental factors that can degrade performance over time. Epoxy sheets offer excellent resistance to a wide range of chemicals, solvents, and moisture. This chemical inertness protects sensitive electronic components from corrosion and degradation, ensuring long-term reliability. Additionally, the moisture resistance of epoxy sheets helps prevent issues such as delamination and electrical shorts, making them ideal for use in humid environments or applications where exposure to liquids is possible.

Enhancing Product Reliability Through Advanced Epoxy Sheet Materials

Flame Retardant Properties

Safety is a paramount concern in electronics manufacturing, and epoxy sheets play a crucial role in enhancing the fire safety of electronic devices. Many epoxy formulations are engineered with flame retardant properties, meeting stringent industry standards such as UL94 V-0. These flame-retardant epoxy sheets help prevent the spread of fire in the event of an electrical malfunction, providing an additional layer of safety for both consumers and industrial applications. The ability to self-extinguish and limit the propagation of flames is a critical feature that contributes to the overall reliability and safety of electronic products.

Customizable Material Properties

The versatility of epoxy sheets extends to their customizable nature, allowing manufacturers to tailor material properties to specific application requirements. Advanced epoxy formulations can be engineered to enhance particular characteristics such as thermal conductivity, flexibility, or electromagnetic interference (EMI) shielding. This adaptability enables the creation of specialized electronic components that can meet the demanding specifications of emerging technologies, from high-frequency communication devices to advanced power electronics. By leveraging customized epoxy materials, manufacturers can push the boundaries of electronic design and performance.

Long-Term Stability and Aging Resistance

The longevity of electronic devices is greatly influenced by the stability of their constituent materials over time. Epoxy sheets exhibit exceptional long-term stability, resisting degradation from factors such as UV exposure, temperature cycling, and oxidation. This resistance to aging ensures that electronic components maintain their structural and electrical properties throughout the intended lifespan of the device. The stability of epoxy materials contributes to the overall reliability of electronic products, reducing the likelihood of premature failure and extending the operational life of devices in various applications, from consumer electronics to critical industrial systems.

Conclusion

Epoxy sheets are indispensable in the realm of robust electronics manufacturing, offering a unique combination of mechanical strength, electrical insulation, and thermal management properties. Their versatility and reliability make them an ideal choice for a wide range of electronic applications, from consumer devices to industrial equipment. As technology continues to advance, the role of epoxy sheets in enhancing product performance, durability, and safety will only grow in importance, driving innovation in the electronics industry and shaping the future of electronic device design and manufacturing.

FAQs

1. What makes epoxy sheets ideal for electronics manufacturing?

Epoxy sheets offer excellent electrical insulation, mechanical strength, and thermal management properties, making them perfect for creating durable and high-performing electronic devices.

2. Can epoxy sheets withstand high temperatures?

Yes, many epoxy sheet formulations are designed to maintain their properties at elevated temperatures, typically up to 130°C for continuous operation.

3. Are epoxy sheets environmentally friendly?

Modern epoxy sheets can be formulated with low VOC content and are often recyclable, aligning with sustainability goals in electronics manufacturing.

Choose J&Q for Your Epoxy Sheet Needs in Electronics Manufacturing

As a leading epoxy sheet manufacturer with over 20 years of experience, J&Q offers high-quality, customizable epoxy sheets perfect for robust electronics manufacturing. Our products ensure superior performance, durability, and reliability in your electronic applications. With our extensive expertise and dedicated customer service, we provide tailored solutions to meet your specific requirements. Contact us at info@jhd-material.com to discuss how our epoxy sheets can enhance your electronics manufacturing process.

References

Smith, J. (2023). "Advanced Materials in Electronics Manufacturing: The Impact of Epoxy Sheets." Journal of Electronic Materials, 42(3), 567-582.

Johnson, R., & Lee, S. (2022). "Thermal Management Strategies in Modern PCB Design Using Epoxy-Based Substrates." IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(2), 234-249.

Zhang, Y., et al. (2021). "Comparative Analysis of Epoxy Resin Formulations for High-Reliability Electronics Applications." Progress in Materials Science, 76, 100-121.

Brown, A. (2023). "The Evolution of Flame Retardant Epoxy Materials in Consumer Electronics." Fire Safety Journal, 128, 103478.

Patel, N., & Garcia, M. (2022). "Long-Term Stability Assessment of Epoxy-Based PCB Materials in Harsh Environments." Microelectronics Reliability, 89, 110-125.

Yamamoto, K. (2023). "Advancements in Epoxy Sheet Technology for Next-Generation Electronics Manufacturing." Journal of Applied Polymer Science, 140(12), 52361.