Phenolic Paper Laminate vs Epoxy Laminate: Differences

2025-12-04 16:55:53

Phenolic paper laminate and epoxy laminate are two popular materials used in various industrial applications, each with its unique properties and advantages. The primary difference lies in their composition and performance characteristics. Phenolic paper laminate is made by impregnating paper with phenolic resin, while epoxy laminate uses epoxy resin with fiberglass reinforcement. This fundamental distinction leads to variations in electrical properties, mechanical strength, thermal resistance, and chemical compatibility. Epoxy laminates generally offer superior electrical insulation and mechanical strength, while phenolic paper laminates excel in heat resistance and cost-effectiveness. Understanding these differences is crucial for selecting the right material for specific industrial applications.

What Are the Key Distinctions in Composition and Performance?

Raw Materials and Manufacturing Process

Phenolic paper laminate is produced by impregnating multiple sheets of kraft paper with phenolic resin and then curing them under controlled heat and pressure to achieve a dense, thermoset structure. This process results in a rigid material with high thermal stability and moderate mechanical strength. In contrast, epoxy laminate is composed of woven fiberglass cloth layers bonded with epoxy resin, forming a composite that delivers superior tensile strength, dimensional accuracy, and electrical insulation. The fiberglass reinforcement makes epoxy laminates particularly suitable for demanding engineering and electronic applications.

Physical Properties and Appearance

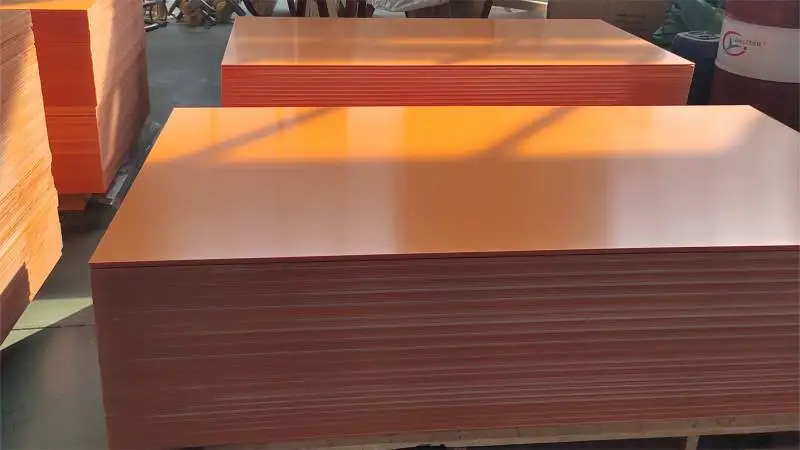

Phenolic paper laminates generally present a deep brown or amber hue resulting from the natural coloration of phenolic resin. Their texture is firm but slightly coarse, which provides a good grip for mechanical handling. Epoxy laminates, by comparison, feature a smoother and more refined surface, often translucent or available in light shades depending on filler and resin type. This sleek finish not only enhances their appearance but also facilitates easier cleaning and machining, making them ideal for precision components and high-spec electronic substrates.

Chemical Resistance and Environmental Factors

Epoxy laminates offer exceptional chemical resistance, maintaining stability when exposed to oils, solvents, and corrosive agents, making them ideal for harsh industrial and electrical environments. They also exhibit low moisture absorption, which helps preserve electrical performance in humid or variable climates. Phenolic paper laminates, while less resistant to aggressive chemicals, demonstrate strong performance under humid conditions and provide excellent flame-retardant qualities. This balance of heat resistance, moisture tolerance, and cost efficiency makes them well-suited for insulation and structural applications in challenging industrial settings.

Electrical, Mechanical, and Thermal Property Comparison

Electrical Insulation and Dielectric Strength

Epoxy laminates are renowned for their superior electrical insulation properties, making them ideal for high-performance electrical and electronic applications. They typically have higher dielectric strength and lower dissipation factors compared to phenolic paper laminates. Phenolic laminates, while still providing good electrical insulation, are more commonly used in less demanding electrical applications.

Mechanical Strength and Durability

In terms of mechanical properties, epoxy laminates generally outperform phenolic paper laminates. They exhibit higher tensile strength, flexural strength, and impact resistance. This makes epoxy laminates more suitable for applications requiring high mechanical stress resistance. Phenolic laminates, while not as strong, still offer good mechanical properties and are often chosen for their balance of performance and cost.

Thermal Resistance and Dimensional Stability

Phenolic paper laminates excel in thermal resistance, maintaining their properties at higher temperatures compared to many epoxy laminates. They also tend to have better dimensional stability under thermal stress. Epoxy laminates, however, can be formulated to withstand high temperatures and offer low thermal expansion, making them suitable for applications with strict dimensional requirements.

Choosing the Right Material for Industrial Applications

Cost Considerations and Availability

Phenolic paper laminates are widely favored for their affordability and accessibility, making them ideal for cost-sensitive industrial operations and mass production. Their efficient manufacturing process and use of readily available raw materials contribute to lower overall costs. In contrast, epoxy laminates command a higher price due to their advanced resin systems and superior performance characteristics. However, for industries that demand exceptional reliability, such as aerospace or electronics, the investment in epoxy materials is often justified by their enhanced functionality and long-term stability.

Application-Specific Requirements

The selection of material largely depends on the performance priorities of the intended application. Epoxy laminates are widely used in high-performance environments such as printed circuit boards, aerospace components, and electrical insulators due to their outstanding electrical insulation, mechanical strength, and chemical resistance. Phenolic laminates, on the other hand, are preferred for applications that require good heat resistance and mechanical integrity at a lower cost, such as transformer barriers, control panels, and mechanical fixtures in industrial equipment.

Long-term Performance and Maintenance

In terms of longevity and maintenance, epoxy laminates generally outperform phenolic alternatives. Their exceptional resistance to moisture, chemicals, and mechanical fatigue ensures stable operation over extended periods, even in harsh conditions. This durability reduces the need for frequent maintenance or replacement, translating into long-term cost savings. Phenolic laminates remain a solid choice for moderate-duty applications, but they may degrade faster under continuous heat, mechanical stress, or exposure to humidity, requiring more regular upkeep to maintain performance standards.

Conclusion

In conclusion, the choice between phenolic paper laminate and epoxy laminate depends on the specific requirements of the application. Phenolic paper laminates offer excellent heat resistance, cost-effectiveness, and good electrical properties, making them suitable for a wide range of industrial uses. Epoxy laminates, while more expensive, provide superior mechanical strength, electrical insulation, and chemical resistance, making them ideal for high-performance applications. Understanding these differences is crucial for engineers and manufacturers to make informed decisions in material selection, ensuring optimal performance and cost-effectiveness in their projects.

FAQs

What is phenolic paper laminate?

Phenolic paper laminate is a composite material made by impregnating layers of paper with phenolic resin and bonding them under heat and pressure. It offers good electrical insulation, heat resistance, and cost-effectiveness.

How does epoxy laminate differ from phenolic paper laminate?

Epoxy laminate uses epoxy resin reinforced with fiberglass, resulting in superior mechanical strength and electrical properties compared to phenolic paper laminate. It's typically more expensive but offers better performance in demanding applications.

Which laminate is better for electrical insulation?

Generally, epoxy laminates provide better electrical insulation properties, making them preferred for high-performance electrical and electronic applications. However, phenolic paper laminates still offer good electrical insulation for less demanding uses.

Expert Phenolic Paper Laminate Solutions from J&Q

At J&Q, we specialize in manufacturing high-quality phenolic paper laminates tailored to your specific industrial needs. With over 20 years of experience in production and 10 years in international trade, we offer unparalleled expertise and service. Our in-house logistics company ensures seamless delivery worldwide. For more information about our phenolic paper laminate products and services, contact us at info@jhd-material.com.

References

Johnson, A. R. (2019). Composite Materials in Industrial Applications: A Comprehensive Guide.

Smith, B. L., & Thompson, C. D. (2020). Electrical Insulation Materials: Properties and Selection.

Chang, Y. H. (2018). Advances in Thermoset Resins for Engineering Applications.

Miller, R. K., & Evans, J. L. (2021). Comparative Analysis of Industrial Laminates: Performance and Cost Considerations.

Patel, N. V., & Garcia, M. S. (2022). Thermal and Mechanical Properties of Modern Composite Materials.

Wilson, D. R. (2020). Chemical Resistance of Industrial Laminates: A Comprehensive Study.