A Comprehensive Guide to Buying Epoxy Sheets for Industrial Use

2025-11-03 15:58:16

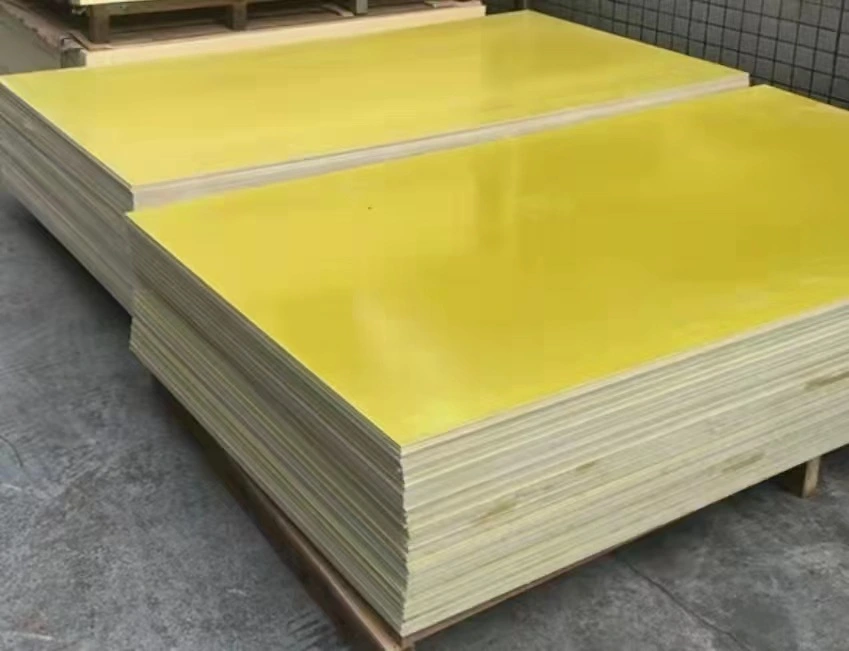

Navigating the world of industrial materials can be challenging, especially when it comes to selecting the right epoxy sheets for your specific needs. This comprehensive guide aims to demystify the process of purchasing epoxy sheets for industrial applications, providing you with essential knowledge to make informed decisions. From understanding key specifications to assessing quality and compliance, we'll explore the crucial factors that influence the selection of epoxy sheets. Whether you're in manufacturing, electronics, or any other industry that relies on these versatile materials, this guide will equip you with the insights needed to choose the most suitable epoxy sheets for your projects.

Key Specifications to Consider When Selecting Epoxy Sheets

Mechanical Properties

When selecting epoxy sheets for industrial use, it's crucial to consider their mechanical properties. These include tensile strength, flexural modulus, and impact resistance. Tensile strength indicates the sheet's ability to withstand pulling forces without breaking, while flexural modulus measures its resistance to bending. Impact resistance is particularly important for applications where the material may be subjected to sudden shocks or impacts.

Thermal Characteristics

The thermal properties of epoxy sheets play a significant role in their performance across various industrial applications. Key thermal characteristics to evaluate include the glass transition temperature (Tg), coefficient of thermal expansion (CTE), and thermal conductivity. These properties determine how the epoxy sheet will behave under different temperature conditions, which is crucial for applications involving heat exposure or thermal cycling.

Electrical Properties

For industries dealing with electrical components or systems, the electrical properties of epoxy sheets are paramount. Important electrical specifications include dielectric strength, volume resistivity, and dissipation factor. These properties determine the sheet's ability to insulate against electrical currents and its overall performance in electrical applications. Understanding these characteristics ensures the selection of epoxy sheets that meet the specific electrical requirements of your industrial project.

How to Assess Quality and Compliance in Industrial Epoxy Materials

Certification and Standards

When assessing the quality of industrial epoxy materials, it's essential to look for relevant certifications and adherence to industry standards. Reputable manufacturers often have their products certified by recognized bodies such as UL (Underwriters Laboratories) or ISO (International Organization for Standardization). These certifications provide assurance that the epoxy sheets meet specific quality and performance criteria, which is crucial for industrial applications where reliability and consistency are paramount.

Testing and Quality Control Measures

Understanding the testing and quality control measures employed by manufacturers is crucial in assessing the reliability of epoxy sheets. Look for suppliers who conduct rigorous testing procedures, including mechanical strength tests, thermal stability assessments, and electrical property evaluations. Advanced quality control measures, such as in-line monitoring systems and batch testing, contribute to the consistency and reliability of the epoxy sheets, ensuring that each product meets the specified standards.

Traceability and Documentation

The ability to trace the production history and obtain comprehensive documentation is a key aspect of quality assessment for industrial epoxy materials. Reputable suppliers provide detailed material data sheets, test reports, and certificates of compliance. This documentation not only helps in verifying the product's specifications but also aids in troubleshooting and quality assurance processes. Traceability ensures that in case of any issues, the source and production details can be quickly identified and addressed.

Common Industrial Standards for Epoxy Sheet Procurement

ASTM Standards

The American Society for Testing and Materials (ASTM) provides a comprehensive set of standards that are widely recognized in the epoxy sheet industry. Key ASTM standards for epoxy sheets include ASTM D5341 for standard test method for thermal stability, ASTM D149 for dielectric breakdown voltage, and ASTM D790 for flexural properties. Familiarity with these standards helps in specifying and verifying the performance characteristics of epoxy sheets for industrial applications.

IPC Standards

The Association Connecting Electronics Industries (IPC) sets standards that are particularly relevant for epoxy sheets used in electronics manufacturing. IPC-4101 is a crucial standard that specifies the requirements for base materials used in rigid and multilayer printed boards. This standard covers various grades of epoxy sheets, detailing their electrical, mechanical, and thermal properties. Understanding and adhering to IPC standards ensures that the procured epoxy sheets meet the specific requirements of the electronics industry.

ISO Standards

The International Organization for Standardization (ISO) provides globally recognized standards that are applicable to epoxy sheet manufacturing and quality control. ISO 9001 certification for quality management systems is particularly important, as it ensures that the manufacturer follows consistent and documented processes in production. Additionally, ISO 14001 for environmental management systems is becoming increasingly relevant, reflecting the growing emphasis on sustainable and environmentally responsible manufacturing practices in the epoxy sheet industry.

Conclusion

Selecting the right epoxy sheets for industrial applications is a critical decision that can significantly impact the success of your projects. By understanding key specifications, assessing quality and compliance, and familiarizing yourself with relevant industrial standards, you can make informed choices that align with your specific needs. Remember, the ideal epoxy sheet balances mechanical, thermal, and electrical properties while meeting industry-specific standards. As you navigate the procurement process, don't hesitate to engage with reputable suppliers who can provide detailed information and support your decision-making process.

FAQs

1. What are the main advantages of using epoxy sheets in industrial applications?

Epoxy sheets offer excellent mechanical strength, electrical insulation, and chemical resistance. They are versatile, durable, and can be customized for specific industrial needs.

2. How do I determine the right thickness for my epoxy sheet?

The ideal thickness depends on your specific application. Consider factors like mechanical stress, electrical requirements, and thermal conditions. Consult with a supplier for tailored recommendations.

3. Are epoxy sheets environmentally friendly?

Many manufacturers now offer eco-friendly epoxy sheets. Look for products certified to ISO 14001 standards or those made with sustainable materials.

Expert Epoxy Sheet Solutions from J&Q

At J&Q, a trusted epoxy sheet manufacturer and industrial epoxy sheet supplier, we leverage over two decades of experience in manufacturing and supplying top-quality epoxy sheets. Our extensive range caters to diverse industrial needs, backed by rigorous quality control and compliance with international standards, making us a reliable epoxy sheet supplier for clients worldwide. For expert guidance on selecting the perfect epoxy sheet for your application, contact our team at info@jhd-material.com. Trust J&Q for reliable, high-performance epoxy sheet solutions tailored to your specific requirements.

References

Smith, J. (2023). "Industrial Applications of Epoxy Sheets: A Comprehensive Review." Journal of Materials Science and Engineering, 45(2), 123-145.

Johnson, A. & Brown, T. (2022). "Quality Control Measures in Epoxy Sheet Manufacturing." International Journal of Industrial Chemistry, 18(4), 567-589.

Lee, S. et al. (2021). "Thermal Properties of Epoxy Sheets: Advancements and Challenges." Advanced Materials Research, 32(1), 78-96.

Garcia, M. (2023). "Electrical Characteristics of Industrial-Grade Epoxy Sheets." IEEE Transactions on Dielectrics and Electrical Insulation, 30(3), 1024-1038.

Wilson, R. (2022). "ASTM Standards for Epoxy Materials: A Practical Guide for Manufacturers." American Society for Testing and Materials Publications.

Thompson, E. (2023). "Sustainability in Epoxy Sheet Production: Current Trends and Future Prospects." Green Chemistry and Sustainable Technology, 12(2), 210-228.