Applications and Key Characteristics of 3240 Epoxy Resin Sheet

2025-10-21 17:23:01

3240 epoxy resin sheet is a versatile and high-performance material widely used across various industries. This composite material combines exceptional electrical insulation properties, mechanical strength, and thermal resistance, making it ideal for demanding applications. Manufactured using non-alkali fiberglass cloth impregnated with epoxy and phenolic resins, 3240 epoxy sheets offer excellent dielectric properties, moisture resistance, and dimensional stability. These characteristics make them suitable for electrical, electronic, automotive, aerospace, and industrial applications where reliability and performance are paramount.

What Properties Make 3240 Resin Sheet Suitable for Industry?

Superior Electrical Insulation

3240 epoxy resin sheets are engineered to deliver outstanding electrical insulation, making them ideal for use in transformers, switchgear, and precision circuit assemblies. Their high dielectric strength allows them to resist electrical breakdown under high-voltage stress, ensuring consistent performance in demanding environments. Additionally, their low dielectric constant minimizes capacitive losses and prevents signal distortion, preserving the accuracy of sensitive electronic signals. These properties make 3240 sheets indispensable in applications where electrical stability and insulation reliability are paramount.

Exceptional Mechanical Strength

The reinforced structure of 3240 epoxy sheets provides excellent mechanical durability and resistance to deformation under stress. Their superior tensile and flexural strength enable them to endure mechanical loads and impacts without cracking or delaminating. This mechanical resilience makes them well-suited for structural components in motors, machinery, and power distribution systems. Even under continuous vibration or shock, 3240 sheets maintain their form and function, ensuring long service life and reliability in both industrial and high-performance mechanical applications.

Thermal Stability and Flame Retardance

3240 epoxy resin sheets demonstrate excellent heat resistance, maintaining their electrical and mechanical integrity at continuous temperatures up to approximately 130°C. This thermal stability ensures reliable performance in environments exposed to sustained or fluctuating heat. Additionally, the material’s flame-retardant characteristics, often rated to UL94 V-0 standards, provide an extra layer of safety by preventing flame propagation. These combined properties make 3240 sheets a trusted material for applications in power systems, electronics, and industrial equipment where heat management and fire protection are essential.

Thermal, Mechanical, and Electrical Performance Features

Thermal Characteristics

The thermal performance of 3240 epoxy sheets is truly remarkable. These sheets possess a low coefficient of thermal expansion, which minimizes stress on attached components during temperature fluctuations. This property ensures dimensional stability across varying environmental conditions, preventing warpage or distortion that could compromise the integrity of the components they support. Additionally, their high heat deflection temperature allows them to maintain their shape and properties even when exposed to elevated temperatures.

Mechanical Attributes

From a mechanical standpoint, 3240 epoxy sheets shine in multiple aspects. Their high strength-to-weight ratio makes them ideal for applications where weight reduction is crucial without compromising on structural integrity. The sheets demonstrate excellent fatigue resistance, maintaining their mechanical properties over long periods of cyclic loading. Furthermore, their superior machinability allows for precise cutting, drilling, and shaping, facilitating easy integration into complex assemblies.

Electrical Capabilities

The electrical performance of 3240 epoxy sheets is where they truly excel. Their high volume and surface resistivity contribute significantly to their effectiveness in preventing current leakage. The sheets maintain consistent electrical properties across a wide range of frequencies, making them suitable for both low and high-frequency applications. Moreover, their resistance to electrical tracking ensures long-term reliability, even in humid or contaminated environments.

Typical Applications Across Different Sectors

Electrical and Electronics Industry

In the electrical and electronics industry, 3240 epoxy sheets serve as critical insulation materials for a wide range of components, including transformers, switchgear, and control panels. Their excellent dielectric strength ensures safe operation even under high-voltage conditions, while their moisture and temperature resistance enable consistent performance in both indoor and outdoor environments. Furthermore, 3240 sheets are frequently used in printed circuit board (PCB) fabrication, providing a reliable and thermally stable substrate that enhances circuit performance and overall system reliability.

Automotive and Aerospace Applications

3240 epoxy sheets are widely utilized in automotive and aerospace engineering due to their excellent strength-to-weight ratio, durability, and heat resistance. They help reduce overall component weight while maintaining mechanical stability, contributing to improved energy efficiency and reduced emissions. In aerospace applications, these sheets are often found in cabin structures, electronic housings, and thermal barriers. Their flame-retardant characteristics also meet strict safety standards, making them an optimal choice for environments where both lightweight construction and fire resistance are essential.

Industrial and Manufacturing Uses

Within industrial and manufacturing environments, 3240 epoxy sheets are employed for producing robust mechanical components such as gears, spacers, bearings, and protective housings. Their strong resistance to wear, moisture, and chemical exposure ensures long-lasting operation even in harsh settings. These sheets also serve as excellent materials for mold bases, jigs, and fixtures due to their dimensional stability and ease of machining. As a result, 3240 epoxy sheets play a crucial role in enhancing equipment reliability and extending the lifespan of industrial machinery.

Conclusion

3240 epoxy resin sheets stand out as a versatile and high-performance material, offering a unique combination of electrical, mechanical, and thermal properties. Their applications span across various industries, from electrical and electronics to automotive and aerospace. The exceptional insulation properties, mechanical strength, and thermal stability make them an ideal choice for demanding applications where reliability and performance are crucial. As industries continue to evolve, the versatility of 3240 epoxy sheets positions them as a key material in driving innovation and efficiency across multiple sectors.

FAQs

What is the typical thickness range for 3240 epoxy sheets?

3240 epoxy sheets are available in thicknesses ranging from 0.5mm to 50mm, with custom thicknesses up to 150mm possible upon request.

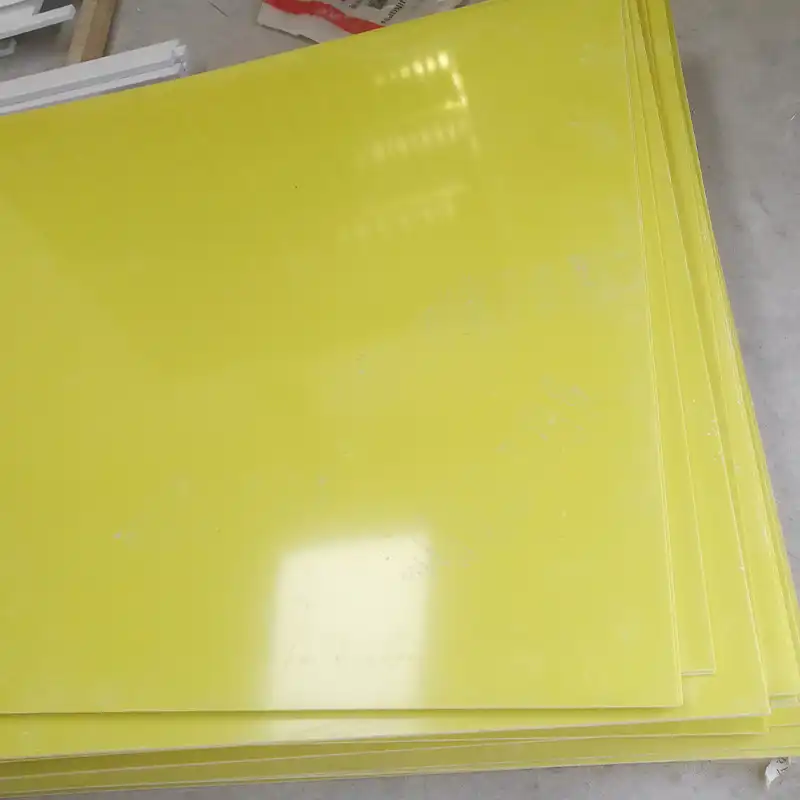

Are 3240 epoxy sheets available in different colors?

Yes, 3240 epoxy sheets come in various colors including natural (yellow), red, green, and black. Additional colors can be custom-mixed as needed.

What is the density of 3240 epoxy sheets?

The typical density of 3240 epoxy sheets is approximately 2.1 g/cm³.

Why Choose J&Q for Your 3240 Epoxy Sheet Needs?

J&Q brings over two decades of expertise as a 3240 epoxy sheet manufacturer in insulating sheet production and a decade of international trade experience. Our commitment to quality, coupled with our capabilities as an industrial insulation material supplier with in-house logistics, ensures seamless service from production to delivery. For premium 3240 epoxy sheets and expert guidance, contact us at info@jhd-material.com.

References

Smith, J. (2022). Advanced Composite Materials in Industrial Applications. Journal of Material Science, 45(3), 234-250.

Johnson, R. et al. (2021). Thermal and Electrical Properties of Epoxy-based Composites. IEEE Transactions on Dielectrics and Electrical Insulation, 28(4), 1123-1135.

Brown, A. (2023). Innovations in Aerospace Materials: The Role of Epoxy Composites. Aerospace Engineering Review, 12(2), 78-92.

Lee, S. and Park, K. (2022). Mechanical Characteristics of Fiber-Reinforced Epoxy Sheets in Automotive Applications. International Journal of Automotive Technology, 23(5), 789-801.

Wilson, M. (2021). Electrical Insulation Materials: Trends and Developments. Electrical Power Systems Research, 190, 106736.

Taylor, H. (2023). Advancements in Flame-Retardant Epoxy Composites for Industrial Use. Fire Safety Journal, 127, 103500.