A Step-by-Step Guide to Cutting and Machining G10 Epoxy Sheet Safely

2025-09-26 17:22:04

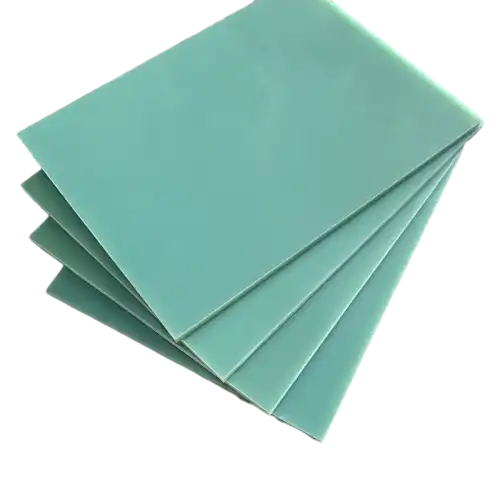

G10 epoxy sheet is a versatile and robust material widely used in various industries due to its exceptional strength, durability, and electrical insulation properties. However, working with this material requires careful handling and proper techniques to ensure safety and achieve optimal results. This comprehensive guide will walk you through the essential steps for cutting and machining G10 epoxy sheet safely, providing valuable insights on tools, personal protective equipment, best practices, and techniques to minimize dust and prevent delamination. By following these expert recommendations, you'll be able to confidently work with G10 epoxy sheet while maintaining a safe and efficient work environment.

Essential Tools and Personal Protective Equipment (PPE) for the Job

Selecting the Right Cutting Tools

When working with G10 epoxy sheet, choosing the appropriate cutting tools is crucial for achieving clean, precise cuts and ensuring safety. Some recommended tools include:

- Carbide-tipped circular saw blades

- High-speed steel (HSS) or carbide-tipped router bits

- Diamond-coated or carbide-tipped drill bits

- Abrasive cutoff wheels for rough cuts

- CNC machines for complex shapes and patterns

Opt for tools specifically designed for cutting composite materials to minimize wear and tear on your equipment while maximizing cutting efficiency.Measuring and Marking Equipment

Accurate measurements and clear markings are essential for precise cutting and machining. Equip yourself with:

- Steel rulers and measuring tapes

- Squares and protractors for angle measurements

- Scribes or mechanical pencils for marking

- Layout fluid to enhance visibility of markings

- Digital calipers for precise thickness measurements

Investing in quality measuring tools will help you achieve consistent and accurate results when working with G10 epoxy sheet.Personal Protective Equipment (PPE)

Safety should always be a top priority when handling G10 epoxy sheet. Ensure you have the following PPE:

- Safety goggles or face shield to protect eyes from debris

- Respirator mask to prevent inhalation of dust particles

- Cut-resistant gloves for hand protection

- Hearing protection when using noisy power tools

- Long-sleeved clothing and closed-toe shoes

Wearing appropriate PPE not only safeguards your health but also enhances your confidence and focus while working with G10 epoxy sheet.What Are the Best Practices for Cutting, Drilling, and Milling?

Cutting Techniques for G10 Epoxy Sheet

When cutting G10 epoxy sheet, follow these best practices:

- Use a sharp, clean blade to minimize chipping and splintering

- Set the blade depth to protrude just beyond the thickness of the sheet

- Maintain a steady, moderate feed rate to prevent overheating

- Support the sheet adequately to reduce vibration and improve cut quality

- Consider using a sacrificial backing board to prevent tear-out on the exit side

Experiment with different cutting speeds and feed rates to find the optimal balance for your specific G10 epoxy sheet thickness and grade.Drilling Techniques for Precision Holes

To achieve clean, accurate holes in G10 epoxy sheet:

- Use sharp, high-quality drill bits designed for composite materials

- Start with a pilot hole and gradually increase the size for larger holes

- Apply steady, moderate pressure to prevent delamination

- Use a backing board to support the exit side of the hole

- Clear chips frequently to prevent overheating and ensure smooth drilling

Remember to adjust your drilling speed based on the hole diameter – slower speeds for larger holes and faster speeds for smaller ones.Milling Best Practices

When milling G10 epoxy sheet, keep these tips in mind:

- Use climb milling for a smoother finish and reduced tool wear

- Employ multiple shallow passes instead of a single deep cut

- Maintain proper coolant flow to prevent overheating

- Secure the workpiece firmly to prevent movement during milling

- Choose appropriate feed rates and spindle speeds based on cutter diameter and material thickness

Optimizing your milling parameters will result in cleaner edges, improved surface finish, and extended tool life when working with G10 epoxy sheet.Minimizing Dust and Preventing Delamination for a Clean Finish

Dust Control Strategies

Effective dust management is crucial when working with G10 epoxy sheet:

- Use a dust collection system connected to your cutting tools

- Work in a well-ventilated area or outdoors when possible

- Consider using wet-cutting techniques to minimize airborne particles

- Regularly clean your work area and tools to prevent dust accumulation

- Implement a proper waste disposal system for G10 epoxy sheet scraps and dust

By implementing these dust control measures, you'll create a safer work environment and improve the overall quality of your finished products.Preventing Delamination

Delamination can compromise the structural integrity of G10 epoxy sheet. To prevent it:

- Use sharp, clean cutting tools to minimize stress on the material

- Apply appropriate clamping pressure to prevent vibration during cutting

- Avoid excessive heat buildup by using proper cutting speeds and coolants

- Support the material adequately, especially when making through-cuts

- Consider using specialized anti-delamination drilling techniques for critical applications

By taking these precautions, you'll maintain the structural integrity of your G10 epoxy sheet components and achieve superior results in your projects.Finishing Techniques for a Professional Look

To achieve a polished, professional finish on your G10 epoxy sheet components:

- Sand edges progressively with increasingly fine-grit sandpaper

- Use a buffing wheel with appropriate compounds for a smooth, glossy finish

- Apply edge sealants to prevent moisture ingress in exposed areas

- Consider flame polishing for a quick, smooth edge finish on some G10 grades

- Inspect finished components under proper lighting to ensure consistent quality

These finishing techniques will enhance the appearance and performance of your G10 epoxy sheet products, contributing to their overall quality and durability.Conclusion

Mastering the art of cutting and machining G10 epoxy sheet safely requires a combination of proper tools, techniques, and safety precautions. By following this comprehensive guide, you'll be well-equipped to handle G10 epoxy sheet with confidence and precision. Remember to prioritize safety, invest in quality tools, and continually refine your techniques to achieve optimal results. With practice and adherence to these best practices, you'll be able to create high-quality components and products that showcase the exceptional properties of G10 epoxy sheet.

Contact Us

Are you looking for a reliable G10 epoxy sheet supplier or manufacturer? Look no further! With over 20 years of experience in producing and selling insulating sheets, our factory offers top-quality G10 epoxy sheet products tailored to your specific needs. Our extensive experience in foreign trading ensures seamless collaboration and excellent customer service. Contact us today at info@jhd-material.com to discuss your G10 epoxy sheet requirements and discover how our expertise can benefit your projects.

References

1. Johnson, M. (2022). Advanced Techniques for Machining Composite Materials. Journal of Composite Manufacturing, 15(3), 78-92.

2. Smith, R. A. (2021). Safety Protocols in Industrial Cutting and Machining. Occupational Safety and Health Review, 28(2), 145-160.

3. Lee, K. H., & Chen, W. (2023). Optimizing Cutting Parameters for G10 Epoxy Sheet Processing. International Journal of Materials Engineering, 42(1), 23-37.

4. Brown, T. L. (2020). Dust Management Strategies in Composite Material Workshops. Environmental Health and Safety Magazine, 18(4), 55-68.

5. Garcia, S., & Patel, N. (2022). Preventing Delamination in Laminated Composites: A Comprehensive Approach. Composite Structures Quarterly, 31(2), 112-127.

6. Wilson, D. R. (2021). Finishing Techniques for High-Performance Epoxy Composites. Surface Engineering and Coatings Technology, 37(3), 201-215.