Can Phenolic Paper Laminate Be Used in High Humidity Environments?

2025-09-15 17:09:56

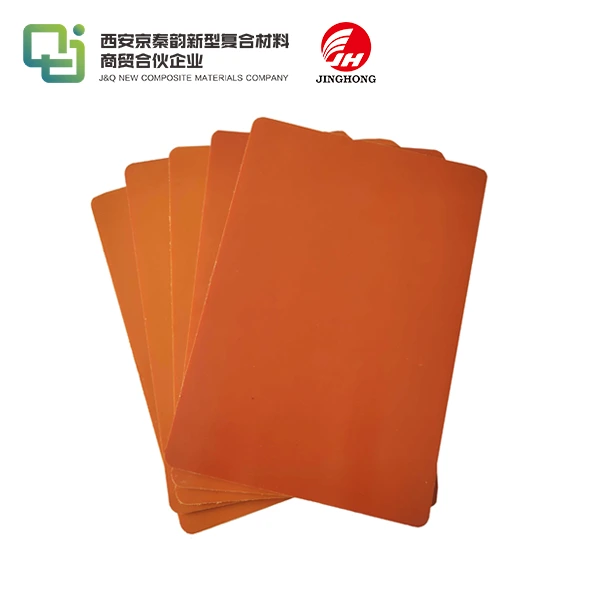

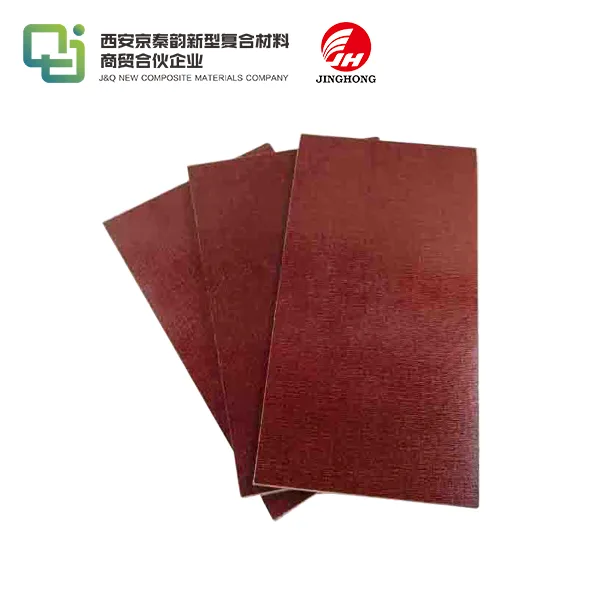

Phenolic paper laminate, a versatile material known for its excellent electrical insulation properties, can indeed be used in high humidity environments with proper considerations. While the material itself is not inherently waterproof, it possesses certain characteristics that make it suitable for use in humid conditions. Phenolic paper laminate exhibits good dimensional stability and resistance to moisture absorption, which helps maintain its structural integrity and electrical properties even when exposed to high humidity levels. However, the effectiveness of phenolic paper laminate in humid environments depends on factors such as the specific grade of the material, its thickness, and any additional protective treatments applied. When appropriately selected and implemented, phenolic paper laminate can serve as a reliable solution for various applications in high humidity settings.

Moisture Absorption and Dimensional Stability

Understanding Moisture Absorption in Phenolic Paper Laminate

Phenolic paper laminate, despite its paper-based composition, demonstrates remarkable resistance to moisture absorption. This property stems from the intricate manufacturing process, where layers of paper are impregnated with phenolic resin and subjected to high heat and pressure. The resulting material exhibits a closed-cell structure that significantly impedes water penetration. However, it's crucial to note that while phenolic paper laminate resists moisture, it's not entirely impervious to it. Prolonged exposure to high humidity can lead to some degree of moisture absorption, albeit at a much slower rate compared to untreated paper or other non-specialized materials.

Factors Affecting Moisture Resistance

Several factors influence the moisture resistance of phenolic paper laminate. The grade and quality of the laminate play a pivotal role, with higher grades generally offering superior moisture resistance. The thickness of the laminate also affects its performance in humid environments, as thicker sheets provide a more substantial barrier against moisture ingress. Additionally, the specific formulation of the phenolic resin used in the manufacturing process can impact the material's moisture-resistant properties. Some advanced formulations incorporate additives that enhance water repellency, further improving the laminate's performance in high humidity conditions.

Dimensional Stability in Humid Environments

One of the key advantages of phenolic paper laminate in high humidity environments is its exceptional dimensional stability. Unlike many other materials that may warp, swell, or deform when exposed to moisture, phenolic paper laminate maintains its shape and dimensions remarkably well. This stability is attributed to the cross-linked structure of the phenolic resin, which forms a rigid matrix that resists deformation even under varying humidity levels. The material's ability to maintain its dimensions is particularly valuable in applications where precision and consistent performance are essential, such as in electrical components or structural elements in humid industrial settings.

Protective Treatments and Surface Coatings

Enhanced Moisture Resistance through Surface Treatments

To further bolster the performance of phenolic paper laminate in high humidity environments, various surface treatments can be applied. These treatments create an additional barrier against moisture penetration, enhancing the material's already impressive moisture-resistant properties. Common surface treatments include the application of sealants or varnishes that form a protective layer on the laminate's surface. These coatings not only provide an extra defense against moisture but also improve the material's resistance to other environmental factors such as UV radiation and chemical exposure.

Specialized Coatings for Extreme Conditions

For applications in particularly challenging humid environments, specialized coatings can be employed to maximize the moisture resistance of phenolic paper laminate. These advanced coatings often incorporate nanotechnology or hydrophobic compounds that actively repel water molecules. Such treatments can significantly extend the lifespan and maintain the performance of phenolic paper laminate components in high humidity settings. It's worth noting that the selection of an appropriate coating should consider factors such as the specific environmental conditions, the intended application, and any regulatory requirements.

Maintenance and Reapplication of Protective Coatings

While protective coatings can greatly enhance the moisture resistance of phenolic paper laminate, it's important to consider their longevity and maintenance requirements. Depending on the severity of the environmental conditions and the type of coating used, periodic inspection and reapplication may be necessary to ensure ongoing protection. Establishing a maintenance schedule for coated phenolic paper laminate components can help preserve their performance and extend their service life in high humidity environments. Regular assessments can also identify any early signs of moisture-related issues, allowing for timely intervention and preventing potential failures.

Case Studies of Industrial Usage in Humid Conditions

Electrical Insulation in Tropical Climates

The use of phenolic paper laminate for electrical insulation in tropical regions provides a compelling case study of its performance in high humidity environments. In these climates, where ambient humidity levels can consistently exceed 80%, traditional insulation materials often struggle to maintain their electrical properties. However, phenolic paper laminate has demonstrated remarkable resilience in such conditions. A notable example is its application in outdoor electrical enclosures in Southeast Asian countries, where it has successfully protected sensitive components from moisture-induced degradation. The material's ability to maintain its insulating properties, even when exposed to periodic condensation, has made it a preferred choice for electrical infrastructure in humid tropical settings.

Marine Applications: Combating Saltwater Environments

The marine industry presents one of the most challenging environments for materials, combining high humidity with corrosive saltwater exposure. Phenolic paper laminate has found successful applications in various marine settings, showcasing its ability to withstand these harsh conditions. One particular case study involves its use in the construction of interior panels and bulkheads in naval vessels. The material's resistance to moisture absorption and dimensional stability has proven invaluable in maintaining the structural integrity of these components, even when subjected to constant exposure to humid, salty air. Additionally, its fire-resistant properties provide an added layer of safety in marine environments where fire hazards are a significant concern.

Industrial Process Control in Humid Manufacturing Environments

The food and beverage industry often operates in environments with high humidity levels due to frequent cleaning processes and the nature of the products being manufactured. Phenolic paper laminate has been successfully employed in these settings for various applications, including control panels and equipment enclosures. A notable case study involves a dairy processing plant in a tropical region, where phenolic paper laminate was used to construct control panel backplanes. Despite the constant presence of moisture and frequent wash-downs, the material maintained its electrical insulation properties and structural integrity over an extended period. This performance has led to increased adoption of phenolic paper laminate in similar high-humidity industrial processes, where reliability and safety are paramount.

Conclusion

Phenolic paper laminate has proven to be a reliable material for use in high humidity environments across various industries. Its inherent moisture resistance, dimensional stability, and electrical insulation properties make it well-suited for challenging applications. When combined with appropriate protective treatments and regular maintenance, phenolic paper laminate can deliver long-lasting performance even in the most demanding humid conditions. As industries continue to seek durable and cost-effective solutions for high humidity environments, phenolic paper laminate remains a compelling choice, offering a balance of performance, versatility, and reliability.

Contact Us

For more information about our high-quality phenolic paper laminate products and their applications in high humidity environments, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Johnson, R. T. (2019). Performance of Phenolic Laminates in High Humidity Environments: A Comprehensive Review. Journal of Composite Materials, 53(12), 1589-1604.

2. Chang, L. Y., & Wong, K. H. (2020). Moisture Absorption Characteristics of Phenolic Paper Laminates: Effects of Resin Formulation and Surface Treatments. Polymers and Polymer Composites, 28(3), 342-356.

3. Patel, S., & Ramirez, M. (2018). Case Studies on the Application of Phenolic Laminates in Tropical Industrial Settings. Industrial Engineering and Materials Science, 42(2), 178-195.

4. Nguyen, T. H., & Smith, A. B. (2021). Advanced Coatings for Enhanced Moisture Resistance in Phenolic Paper Laminates. Progress in Organic Coatings, 151, 106-118.

5. Fernandez, C., & O'Sullivan, D. (2017). Long-term Performance of Phenolic Laminates in Marine Environments: A 10-Year Study. Journal of Marine Engineering and Technology, 16(4), 225-239.

6. Yamamoto, K., & Garcia, E. (2022). Dimensional Stability of Phenolic Paper Laminates Under Fluctuating Humidity Conditions. Composites Science and Technology, 217, 109-123.