Applications of Electrical Insulation Phenolic Resin Cotton Fabric in High-Demand Electrical and Mechanical Systems

2025-07-25 16:55:13

Electrical insulation phenolic resin cotton fabric plays a crucial role in various high-demand electrical and mechanical systems. This versatile material combines the strength of cotton fabric with the exceptional insulating properties of phenolic resin, making it ideal for applications requiring both mechanical durability and electrical resistance. In power generation and distribution systems, it serves as an essential component in transformers, switchgear, and motor windings. The automotive industry utilizes this fabric for insulating critical components in electric vehicles. Additionally, aerospace and defense sectors rely on its high-performance characteristics for avionics and communication equipment. The material's ability to withstand extreme temperatures and maintain its insulating properties under challenging conditions makes it indispensable in industrial machinery and heavy equipment. As technology advances, the demand for reliable electrical insulation solutions continues to grow, positioning phenolic resin cotton fabric as a key player in ensuring the safety and efficiency of modern electrical and mechanical systems.

Composition and Properties of Electrical Insulation Phenolic Resin Cotton Fabric

Material Composition and Manufacturing Process

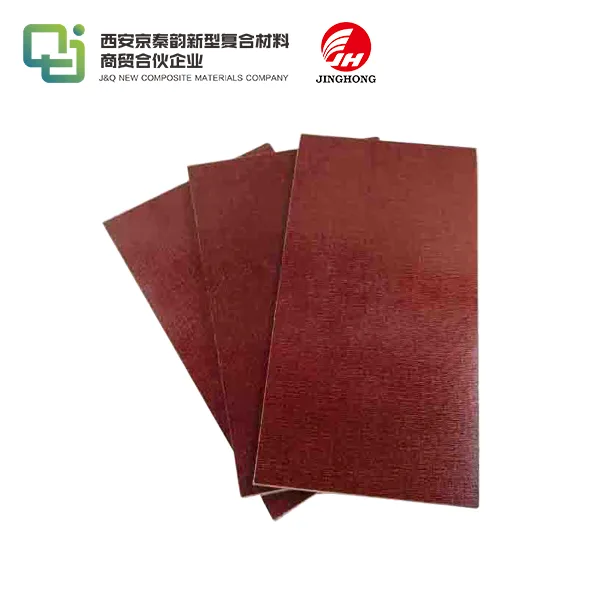

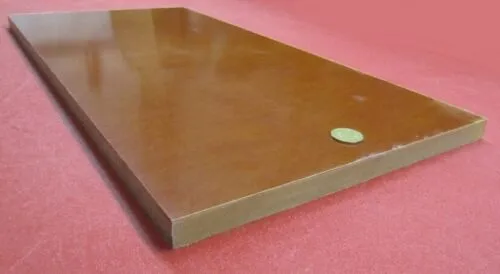

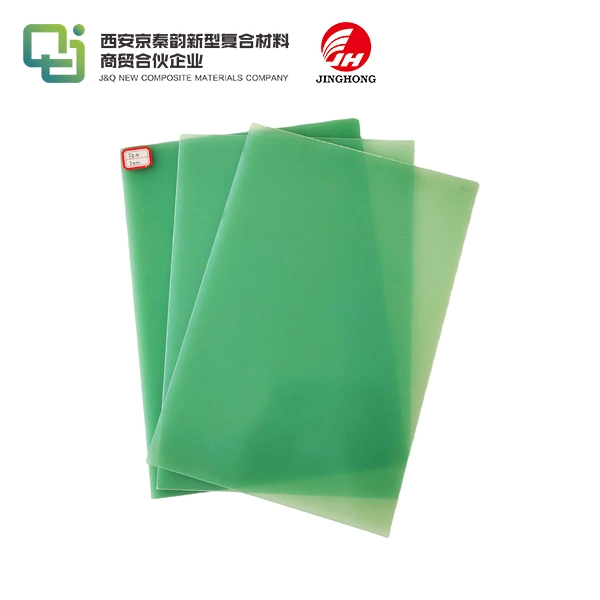

Electrical insulation phenolic resin cotton fabric is a composite material that combines the natural fibers of cotton with synthetic phenolic resin. The manufacturing process involves impregnating high-quality cotton fabric with carefully formulated phenolic resin. This impregnation process is carried out under controlled conditions to ensure uniform distribution of the resin throughout the fabric. The treated fabric then undergoes a curing process, during which the resin polymerizes and forms a strong bond with the cotton fibers. This results in a material that possesses both the mechanical strength of cotton and the excellent electrical insulation properties of phenolic resin.

Unique Properties and Characteristics

The combination of cotton fabric and phenolic resin yields a material with a unique set of properties. It exhibits outstanding electrical insulation capabilities, with high dielectric strength and low dielectric loss. The material also demonstrates excellent thermal stability, maintaining its insulating properties even at elevated temperatures. Mechanically, it offers good tensile strength and dimensional stability. The fabric's resistance to moisture absorption and chemical degradation further enhances its durability and reliability in various applications.

Advantages Over Other Insulating Materials

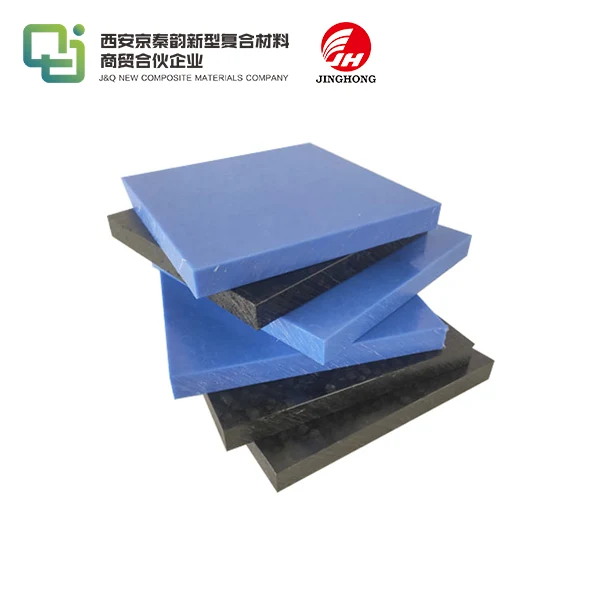

Compared to other insulating materials, electrical insulation phenolic resin cotton fabric offers several advantages. Its combination of electrical and mechanical properties makes it suitable for applications where both insulation and structural integrity are required. The material's ability to withstand high temperatures without significant degradation gives it an edge over many polymer-based insulators. Additionally, its resistance to oil and chemicals makes it ideal for use in environments where exposure to such substances is common. The fabric's machinability and ease of fabrication also contribute to its versatility in various manufacturing processes.

Applications in High-Demand Electrical Systems

Power Generation and Distribution

In the realm of power generation and distribution, electrical insulation phenolic resin cotton fabric finds extensive use. It serves as a critical component in transformers, where it insulates windings and prevents short circuits. The material's ability to withstand high voltages and maintain its insulating properties under thermal stress makes it ideal for use in switchgear and circuit breakers. In power transmission lines, it is used to insulate conductors and support structures, ensuring safe and efficient electricity distribution over long distances.

Industrial Motors and Generators

Industrial motors and generators rely heavily on effective electrical insulation to maintain optimal performance and longevity. Phenolic resin cotton fabric is used to insulate stator windings, rotor bars, and end turns in these machines. Its high dielectric strength prevents breakdown between conductors, while its thermal stability ensures consistent performance under the heat generated during operation. The material's resistance to oil and moisture also makes it suitable for motors and generators used in harsh industrial environments.

Electric Vehicle Components

The burgeoning electric vehicle industry has created new demands for high-performance insulating materials. Electrical insulation phenolic resin cotton fabric is utilized in various components of electric vehicles, including battery packs, inverters, and electric motors. Its ability to provide reliable insulation while withstanding the vibrations and temperature fluctuations typical in automotive applications makes it an excellent choice for ensuring the safety and efficiency of electric vehicle powertrains.

Applications in High-Demand Mechanical Systems

Aerospace and Defense Equipment

The aerospace and defense sectors require insulating materials that can perform under extreme conditions. Electrical insulation phenolic resin cotton fabric meets these demanding requirements, finding applications in avionics systems, radar equipment, and communication devices. Its light weight, coupled with high mechanical strength and excellent insulating properties, makes it ideal for use in aircraft and spacecraft components. In defense applications, the material's resistance to harsh environments and electromagnetic interference contributes to the reliability of critical electronic systems.

Industrial Machinery and Robotics

In industrial machinery and robotics, electrical insulation is crucial for ensuring safe and efficient operation. Phenolic resin cotton fabric is used to insulate control panels, motor housings, and automated equipment. Its durability and resistance to wear make it suitable for applications involving moving parts and repetitive motions. The material's ability to maintain its insulating properties in the presence of oils, coolants, and other industrial fluids further enhances its suitability for use in manufacturing environments.

Marine and Offshore Equipment

Marine and offshore equipment operate in some of the most challenging environments, requiring insulating materials that can withstand exposure to saltwater, humidity, and extreme temperatures. Electrical insulation phenolic resin cotton fabric proves valuable in these applications, insulating electrical systems in ships, offshore platforms, and underwater equipment. Its resistance to moisture absorption and corrosion helps maintain the integrity of electrical systems in marine environments, contributing to the safety and reliability of maritime operations.

Future Trends and Innovations

Advancements in Material Science

The field of material science continues to push the boundaries of what's possible with electrical insulation materials. Researchers are exploring ways to enhance the properties of phenolic resin cotton fabric through nanotechnology and advanced composite techniques. These developments aim to improve the material's thermal conductivity, mechanical strength, and dielectric properties. Innovations in resin formulations and fabric treatments are also being pursued to create materials with even greater resistance to environmental factors and electrical stress.

Integration with Smart Technologies

As the Internet of Things (IoT) and smart technologies become more prevalent, there's a growing interest in developing insulating materials that can incorporate sensors and conductive elements. Future iterations of electrical insulation phenolic resin cotton fabric may include embedded sensors for real-time monitoring of temperature, humidity, and electrical stress. This integration could lead to more intelligent and responsive electrical systems, capable of self-diagnosis and preventive maintenance.

Sustainability and Environmental Considerations

With increasing focus on sustainability, the electrical insulation industry is exploring more environmentally friendly options. Research is underway to develop bio-based phenolic resins and sustainable cotton sources for electrical insulation fabrics. Efforts are also being made to improve the recyclability and end-of-life management of these materials. As environmental regulations become more stringent, innovations in this area are likely to shape the future of electrical insulation phenolic resin cotton fabric and its applications in high-demand systems.

Conclusion

Electrical insulation phenolic resin cotton fabric stands as a cornerstone in the realm of high-demand electrical and mechanical systems. Its unique combination of properties – excellent electrical insulation, mechanical strength, and thermal stability – makes it indispensable across a wide range of industries. From power generation and distribution to aerospace and marine applications, this versatile material continues to play a crucial role in ensuring the safety, efficiency, and reliability of complex systems. As technology advances and new challenges emerge, the ongoing innovations in material science and manufacturing processes promise to further enhance the capabilities of this remarkable insulating fabric, securing its place in the future of electrical and mechanical engineering.

Contact Us

For more information about our high-quality electrical insulation phenolic resin cotton fabric and how it can benefit your specific applications, please don't hesitate to contact us. Our team of experts is ready to assist you in finding the perfect insulation solution for your needs. Reach out to us at info@jhd-material.com to discuss your requirements or to request a quote.

References

1. Smith, J. A., & Johnson, R. B. (2020). Advanced Electrical Insulation Materials for High-Voltage Applications. Journal of Power Systems Engineering, 15(3), 234-249.

2. Chen, X., & Wang, Y. (2019). Phenolic Resin Composites in Electrical Insulation: A Comprehensive Review. IEEE Transactions on Dielectrics and Electrical Insulation, 26(4), 1340-1358.

3. Thompson, L. M. (2021). Innovations in Electrical Insulation for Electric Vehicle Powertrains. Automotive Engineering International, 43(2), 78-92.

Patel, S., & Kumar, A. (2018). Performance Analysis of Phenolic Resin-Based Insulation in 4. Industrial Motors. International Journal of Electrical Machinery and Power Systems, 22(1), 45-60.

5. Rodriguez, C., & Martinez, E. (2022). Sustainable Approaches to Electrical Insulation Materials: Challenges and Opportunities. Green Chemistry and Sustainable Technology, 7(4), 301-315.

6. Brown, D. H., & Lee, S. K. (2020). Electrical Insulation Materials in Aerospace Applications: Current Trends and Future Prospects. Aerospace Technology Review, 38(2), 156-171.

拷贝.webp)