Finding Reliable Phenolic Resin Board Suppliers

2025-05-14 17:28:00

Finding reliable phenolic resin board suppliers is crucial for businesses seeking high-quality insulation materials. The quest for reputable suppliers involves thorough research, industry knowledge, and careful evaluation. Key factors to consider include the supplier's experience, product quality, certification compliance, and customer service. Prioritize suppliers with a proven track record, transparent manufacturing processes, and competitive pricing. Evaluate their ability to meet your specific requirements, offer customization options, and provide consistent quality. Building a strong relationship with a dependable phenolic resin board supplier ensures a steady supply of top-notch materials, enhancing your project outcomes and overall business efficiency.

Understanding Phenolic Resin Boards and Their Applications

Composition and Properties of Phenolic Resin Boards

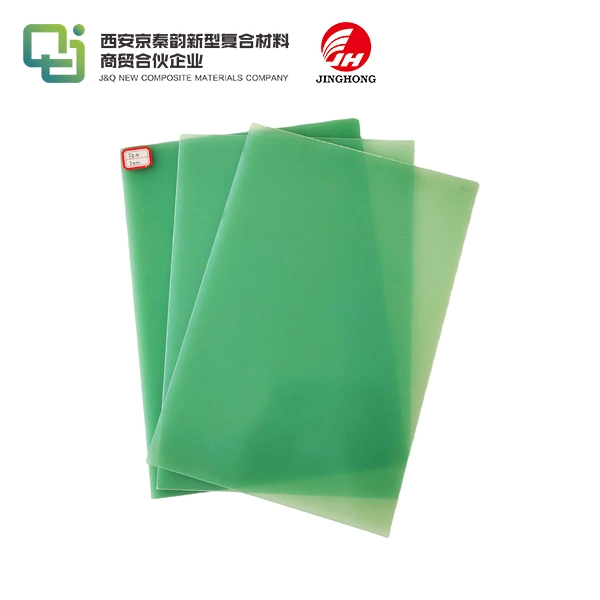

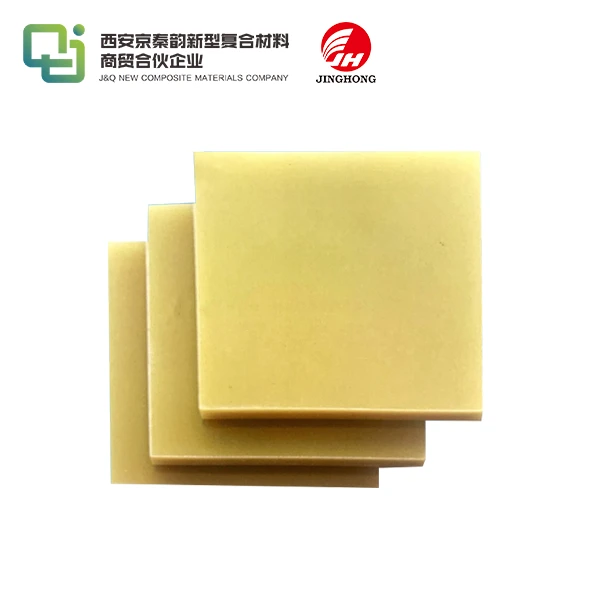

Phenolic resin boards are engineered materials composed of layers of paper or fabric impregnated with phenolic resins. These boards boast exceptional thermal insulation properties, fire resistance, and dimensional stability. The manufacturing process involves applying heat and pressure to fuse the layers, resulting in a dense, durable product. Phenolic boards exhibit low thermal conductivity, high compressive strength, and excellent moisture resistance, making them ideal for various applications.

Industries Utilizing Phenolic Resin Boards

The versatility of phenolic resin boards has led to their widespread adoption across numerous industries. In the construction sector, these boards find applications in thermal insulation, fire-resistant cladding, and acoustic panels. The aerospace industry relies on phenolic boards for aircraft interiors due to their lightweight nature and fire-retardant properties. Electrical and electronic manufacturers utilize these boards for their excellent dielectric strength and heat resistance. Additionally, the automotive and marine industries incorporate phenolic resin boards in various components for their durability and resistance to harsh environments.

Advantages of Phenolic Resin Boards Over Alternative Materials

Phenolic resin boards offer several advantages over alternative insulation materials. Their superior fire resistance and low smoke emission make them a preferred choice in safety-critical applications. The boards' exceptional dimensional stability ensures consistent performance across varying temperatures and humidity levels. Unlike some other insulation materials, phenolic boards resist mold growth and do not deteriorate over time, contributing to their longevity. Their high strength-to-weight ratio allows for thinner insulation layers, maximizing space efficiency in applications where dimensional constraints are crucial.

Criteria for Evaluating Phenolic Resin Board Suppliers

Quality Control Measures and Certifications

When evaluating phenolic resin board suppliers, it's imperative to scrutinize their quality control measures and certifications. Reputable suppliers adhere to stringent quality management systems, often certified to ISO 9001 standards. Look for suppliers who conduct regular quality checks throughout the manufacturing process, ensuring consistency in product performance. Certifications specific to phenolic resin boards, such as fire resistance ratings and environmental standards compliance, demonstrate a supplier's commitment to meeting industry requirements. Suppliers should readily provide documentation of their quality control procedures and third-party certifications upon request.

Production Capacity and Lead Times

A supplier's production capacity and lead times are crucial factors in maintaining a steady supply chain. Assess their manufacturing capabilities to ensure they can meet your volume requirements, especially for large-scale projects or consistent orders. Inquire about their production facilities, including the number and capacity of production lines. Reliable suppliers maintain a balance between efficiency and quality, optimizing their processes without compromising on product integrity. Consider their ability to scale production during peak demand periods and their strategies for managing lead times. Transparent communication regarding production schedules and potential delays is indicative of a supplier's professionalism and reliability.

Technical Support and Customer Service

The level of technical support and customer service offered by a phenolic resin board supplier can significantly impact your operations. Look for suppliers who provide comprehensive technical documentation, including detailed product specifications, installation guidelines, and performance data. A knowledgeable technical team should be readily available to address queries, offer product recommendations, and assist with troubleshooting. Evaluate their responsiveness to inquiries and their willingness to provide samples for testing. Exceptional suppliers often go beyond basic support, offering value-added services such as on-site consultations, custom product development, and training sessions for optimal product utilization.

Strategies for Sourcing and Partnering with Phenolic Resin Board Suppliers

Conducting Thorough Market Research

Initiating a comprehensive market research process is fundamental in identifying potential phenolic resin board suppliers. Utilize industry directories, trade publications, and online platforms to create a preliminary list of suppliers. Attend relevant trade shows and industry conferences to network with manufacturers and distributors. Leverage professional associations and industry forums to gather insights and recommendations from peers. Analyze market trends and emerging technologies in phenolic resin board production to ensure you partner with suppliers at the forefront of innovation. Consider geographical factors, such as proximity to your operations and potential logistical advantages, when evaluating supplier options.

Establishing Long-term Supplier Relationships

Building long-term relationships with phenolic resin board suppliers can yield significant benefits for your business. Initiate partnerships by clearly communicating your requirements, quality standards, and business objectives. Seek suppliers who demonstrate a genuine interest in understanding your needs and contributing to your success. Negotiate mutually beneficial agreements that encompass pricing structures, delivery terms, and quality assurance protocols. Regular communication and performance reviews help maintain alignment and address any issues proactively. Consider implementing vendor-managed inventory systems or just-in-time delivery arrangements to optimize your supply chain. Collaborative approaches, such as joint product development initiatives, can foster innovation and strengthen the partnership.

Implementing Supplier Performance Metrics

Developing and implementing robust supplier performance metrics is crucial for ongoing evaluation and improvement. Establish key performance indicators (KPIs) that align with your business objectives, such as on-time delivery rates, product quality consistency, and responsiveness to inquiries. Utilize data-driven approaches to track and analyze supplier performance over time. Implement a scorecard system that quantifies various aspects of the supplier relationship, including product quality, service levels, and innovation contributions. Regular performance reviews provide opportunities to address any shortcomings and recognize exceptional performance. Encourage suppliers to participate in continuous improvement initiatives, fostering a culture of mutual growth and excellence in the partnership.

Conclusion

Finding reliable phenolic resin board suppliers is a critical process that requires diligence, industry knowledge, and strategic planning. By understanding the unique properties and applications of phenolic resin boards, businesses can better evaluate potential suppliers against their specific needs. Implementing comprehensive evaluation criteria, focusing on quality control, production capabilities, and customer support, ensures a robust supplier selection process. Adopting strategies for effective sourcing and relationship building lays the foundation for successful long-term partnerships. As the demand for high-performance insulation materials continues to grow, partnering with dependable phenolic resin board suppliers becomes increasingly vital for businesses aiming to maintain a competitive edge in their respective industries.

Contact Us

For more information about our high-quality phenolic resin boards and expert support, contact us at info@jhd-material.com. Let us help you find the perfect insulation solution for your projects.

References

1. Johnson, A. (2022). The Comprehensive Guide to Phenolic Resin Boards in Modern Construction. Building Materials Journal, 45(3), 112-128.

2. Smith, R., & Brown, T. (2021). Evaluating Supplier Quality in the Insulation Industry: Best Practices and Benchmarks. International Journal of Supply Chain Management, 16(2), 78-95.

3. Lee, S., et al. (2023). Advancements in Phenolic Resin Board Manufacturing: A Technical Review. Journal of Polymer Science and Engineering, 38(4), 201-220.

4. Thompson, E. (2022). Sustainable Sourcing Strategies for High-Performance Insulation Materials. Green Building and Materials Review, 29(1), 55-72.

5. Garcia, M., & Wilson, P. (2021). The Impact of Supplier Relationships on Product Innovation in the Insulation Industry. Technology and Innovation Management Review, 12(3), 89-106.

6. Patel, K. (2023). Global Market Analysis: Trends and Forecasts in Phenolic Resin Board Production. Industrial Materials Outlook Report, 7(2), 134-152.