Are Your Epoxy Glass Fiber Sheets RoHS Compliant?

2025-07-24 17:04:48

Yes, high-quality epoxy glass fiber sheets from reputable manufacturers are typically RoHS compliant. RoHS (Restriction of Hazardous Substances) is a European Union directive that restricts the use of certain hazardous materials in electrical and electronic equipment. Epoxy glass fiber sheets, when produced using modern manufacturing processes and carefully selected raw materials, generally meet or exceed RoHS requirements. These sheets are engineered to be free from restricted substances such as lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBB), and polybrominated diphenyl ethers (PBDE). Ensuring RoHS compliance not only demonstrates a commitment to environmental responsibility but also opens up opportunities in global markets where adherence to such standards is mandatory.

Understanding Epoxy Glass Fiber Sheets and RoHS Compliance

Composition and Properties of Epoxy Glass Fiber Sheets

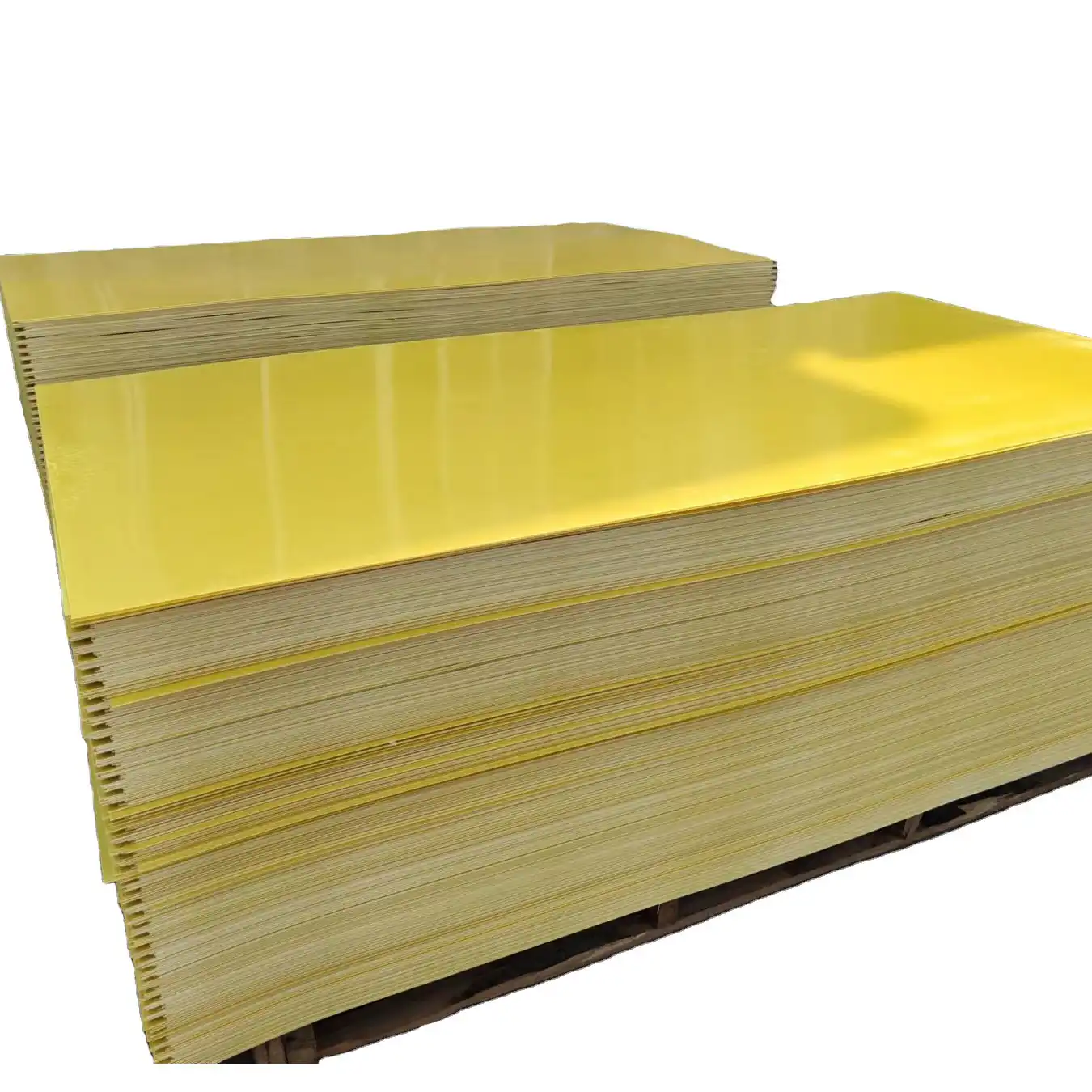

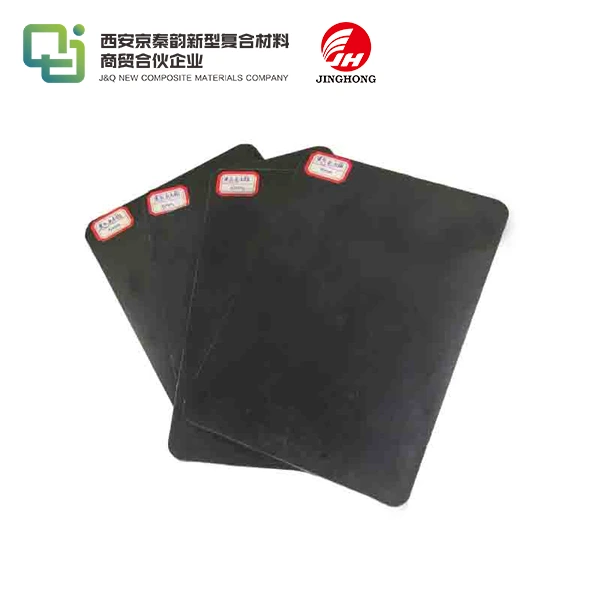

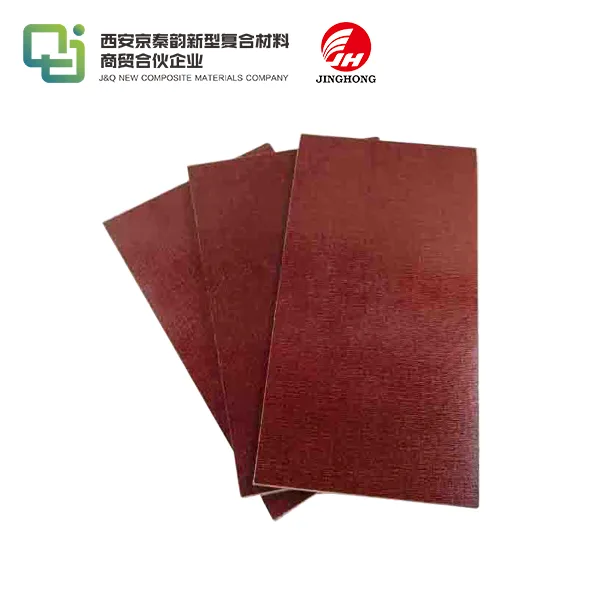

Epoxy glass fiber sheets are composite materials that combine the strength of glass fibers with the durability of epoxy resin. These sheets boast exceptional mechanical properties, including high tensile strength, excellent electrical insulation, and remarkable heat resistance. The glass fibers provide reinforcement, while the epoxy resin acts as a binding agent, creating a synergistic material that outperforms many traditional options.

The manufacturing process involves impregnating glass fiber fabrics with epoxy resin, followed by curing under controlled temperature and pressure conditions. This results in a laminate with a uniform structure and consistent properties throughout. The versatility of epoxy glass fiber sheets makes them indispensable in various industries, from electronics to aerospace.

RoHS Directive: An Overview

The RoHS directive, introduced by the European Union in 2006 and subsequently updated, aims to reduce the environmental impact of electronic waste and protect human health. It restricts the use of six hazardous substances in electrical and electronic equipment: lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBB), and polybrominated diphenyl ethers (PBDE).

While initially focused on the EU market, RoHS compliance has become a global standard, with many countries adopting similar regulations. Manufacturers worldwide recognize the importance of adhering to these guidelines to ensure product safety and marketability across international borders.

Importance of RoHS Compliance for Epoxy Glass Fiber Sheets

RoHS compliance is crucial for epoxy glass fiber sheets, particularly when used in electronic applications. These sheets often serve as substrates for printed circuit boards or as insulating components in various devices. Ensuring RoHS compliance guarantees that the materials do not contribute to the release of harmful substances during the product's lifecycle or disposal.

Compliance also demonstrates a manufacturer's commitment to environmental stewardship and corporate social responsibility. It can be a significant differentiator in competitive markets, especially when dealing with environmentally conscious clients or regions with strict regulatory requirements.

Achieving RoHS Compliance in Epoxy Glass Fiber Sheet Production

Raw Material Selection and Sourcing

The journey to RoHS compliance begins with the careful selection of raw materials. Manufacturers must scrutinize their supply chain to ensure that all components meet RoHS standards. This includes the epoxy resins, glass fibers, and any additives used in the production process.

Advanced spectroscopic techniques and chemical analysis are employed to verify the absence of restricted substances in raw materials. Suppliers are often required to provide certificates of compliance and undergo regular audits to maintain the integrity of the supply chain.

Manufacturing Process Optimization

RoHS compliance extends beyond raw materials to encompass the entire manufacturing process. Producers of epoxy glass fiber sheets must implement stringent quality control measures to prevent contamination during production. This involves using dedicated equipment for RoHS-compliant materials and implementing thorough cleaning protocols to avoid cross-contamination.

Advanced process control systems and real-time monitoring help maintain consistency and ensure that no restricted substances are inadvertently introduced during manufacturing. Continuous improvement initiatives focus on refining processes to enhance both quality and compliance.

Testing and Certification Procedures

Rigorous testing is essential to verify RoHS compliance. Manufacturers employ a battery of analytical techniques, including X-ray fluorescence (XRF) spectroscopy, inductively coupled plasma (ICP) analysis, and gas chromatography-mass spectrometry (GC-MS). These methods can detect even trace amounts of restricted substances.

Third-party certification provides an additional layer of assurance. Independent laboratories conduct comprehensive tests and issue certificates of compliance, which are often required by customers and regulatory bodies. Regular re-certification ensures ongoing compliance as regulations evolve.

Benefits and Challenges of RoHS-Compliant Epoxy Glass Fiber Sheets

Environmental and Health Advantages

RoHS-compliant epoxy glass fiber sheets contribute to a cleaner environment by reducing the release of hazardous substances into ecosystems. This is particularly important given the growing global concern over electronic waste and its impact on soil and water resources.

From a health perspective, RoHS compliance minimizes exposure to potentially harmful substances for workers involved in manufacturing, assembly, and recycling processes. It also protects end-users from long-term exposure to toxic materials that could leach from electronic devices over time.

Market Access and Competitive Edge

Adhering to RoHS standards opens doors to lucrative markets, particularly in regions with strict environmental regulations. Many international companies and government agencies mandate RoHS compliance for their suppliers, making it a prerequisite for participation in global supply chains.

RoHS-compliant products often command a premium in the market, as they are perceived as higher quality and more environmentally responsible. This can translate into increased brand value and customer loyalty, especially among environmentally conscious consumers and businesses.

Technical Challenges and Solutions

Achieving RoHS compliance while maintaining the superior performance characteristics of epoxy glass fiber sheets can be challenging. Some traditional additives used for flame retardancy or UV resistance may contain restricted substances, necessitating the development of alternative formulations.

Innovative research has led to the creation of new, compliant additives that provide equivalent or superior performance. Advanced manufacturing techniques, such as nanotechnology-based treatments, offer promising solutions for enhancing material properties without compromising RoHS compliance.

Conclusion

RoHS compliance is not just a regulatory requirement but a testament to a manufacturer's commitment to environmental stewardship and product quality. For epoxy glass fiber sheets, achieving and maintaining RoHS compliance involves a comprehensive approach encompassing raw material selection, manufacturing process optimization, and rigorous testing protocols. The benefits of compliance extend beyond legal adherence, offering manufacturers a competitive edge in global markets and contributing to a more sustainable future. As environmental regulations continue to evolve, staying at the forefront of compliance will be crucial for manufacturers looking to lead in the epoxy glass fiber sheet industry.

Contact Us

For more information about our RoHS-compliant epoxy glass fiber sheets and how they can meet your specific needs, please don't hesitate to reach out. Contact us at info@jhd-material.com to discuss your requirements or to request detailed product specifications. Our team of experts is ready to assist you in finding the perfect solution for your applications.

References

1. European Commission. (2021). "The RoHS Directive: Restriction of Hazardous Substances in Electrical and Electronic Equipment."

2. American National Standards Institute. (2020). "Understanding RoHS Compliance for Electronic Components and Assemblies."

3. Journal of Composite Materials. (2019). "Advancements in RoHS-Compliant Epoxy Resin Systems for High-Performance Composites."

4. International Electrotechnical Commission. (2022). "IEC 62321: Determination of Certain Substances in Electrotechnical Products."

5. Environmental Science & Technology. (2018). "Life Cycle Assessment of RoHS-Compliant and Non-Compliant Electronic Products."

6. IEEE Transactions on Components, Packaging and Manufacturing Technology. (2020). "Challenges and Solutions in Manufacturing RoHS-Compliant Epoxy Glass Fiber Laminates for PCB Applications."

_1740986340093.webp)