What Is the Standard Thickness of FR4 Epoxy Glass Sheets?

2025-07-16 16:39:18

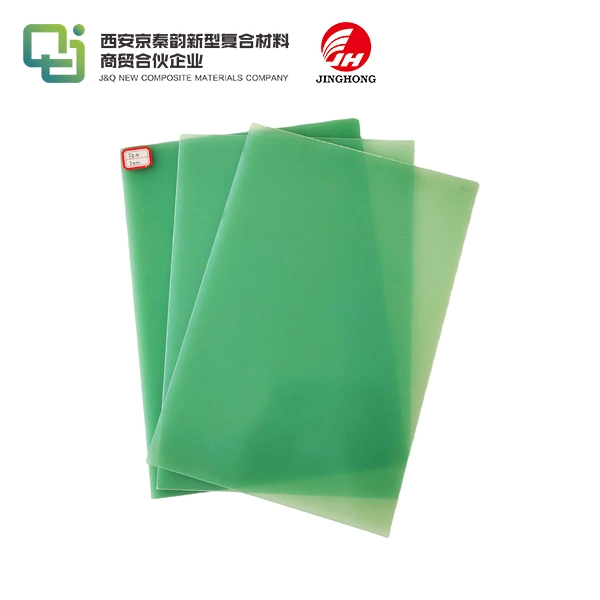

FR4 epoxy glass sheets, also known as FR4 epoxy fiberglass sheets, are widely used in various industries due to their exceptional electrical insulation properties and mechanical strength. When it comes to the standard thickness of these sheets, it's important to note that there isn't a single, universal standard. The thickness of FR4 epoxy glass sheets can vary depending on the specific application and manufacturer. However, common thicknesses range from 0.2mm to 3.2mm, with 1.6mm being a popular choice for many applications. It's crucial to understand that the "standard" thickness can differ based on industry requirements, regional standards, and specific product designs. Always consult with your supplier or manufacturer to determine the most suitable thickness for your particular needs.

Understanding FR4 Epoxy Glass Sheets

Composition and Properties of FR4 Material

FR4 epoxy glass sheets are composite materials composed of woven fiberglass cloth impregnated with epoxy resin. This unique combination results in a material with exceptional electrical insulation properties, mechanical strength, and flame resistance. The "FR" in FR4 stands for "Flame Retardant," indicating its ability to self-extinguish when exposed to fire. The epoxy resin provides excellent adhesion and chemical resistance, while the fiberglass reinforcement enhances the material's dimensional stability and thermal properties.

Applications of FR4 Epoxy Fiberglass Sheets

FR4 epoxy fiberglass sheets find extensive use in various industries due to their versatile properties. In the electronics sector, they serve as the primary material for printed circuit boards (PCBs), providing a stable substrate for electronic components. The automotive industry utilizes FR4 sheets for insulation in electrical systems and control panels. Aerospace applications include structural components and interior panels. Additionally, FR4 sheets are employed in electrical enclosures, transformer insulation, and industrial equipment where high-performance insulation is required.

Advantages of FR4 over Other Materials

FR4 epoxy glass sheets offer several advantages over alternative materials. Their superior electrical insulation properties make them ideal for high-frequency applications. The material's flame-retardant nature enhances safety in electrical systems. FR4 sheets exhibit excellent dimensional stability, maintaining their shape and size even under varying temperature and humidity conditions. Their high strength-to-weight ratio makes them suitable for lightweight yet durable applications. Moreover, FR4 sheets possess good machinability, allowing for easy cutting, drilling, and shaping during manufacturing processes.

Factors Influencing FR4 Sheet Thickness

Industry-Specific Requirements

Different industries have varying requirements for FR4 epoxy glass sheet thickness. In the electronics industry, PCB designs often dictate specific thicknesses to accommodate component mounting and signal integrity. Aerospace applications may require thicker sheets for structural integrity, while automotive uses might prioritize thinner sheets for weight reduction. Industrial equipment manufacturers may opt for thicker FR4 sheets to enhance durability and insulation in harsh environments. Understanding these industry-specific needs is crucial when selecting the appropriate FR4 sheet thickness for a given application.

Electrical and Mechanical Considerations

The thickness of FR4 epoxy fiberglass sheets significantly impacts their electrical and mechanical properties. Thicker sheets generally provide better insulation and higher voltage breakdown strength, making them suitable for high-voltage applications. However, thinner sheets may be preferred in applications requiring flexibility or reduced signal loss in high-frequency circuits. Mechanical considerations include the sheet's ability to withstand physical stress, vibration, and thermal expansion. Balancing these electrical and mechanical factors is essential when determining the optimal FR4 sheet thickness for a specific product or system.

Manufacturing Constraints and Tolerances

The manufacturing process of FR4 epoxy glass sheets imposes certain constraints on achievable thicknesses. Extremely thin sheets may be challenging to produce with consistent quality, while very thick sheets might require specialized equipment or processes. Manufacturing tolerances also play a role in determining the final thickness of FR4 sheets. Tight tolerances may be necessary for precision applications, but they can increase production costs. Understanding these manufacturing constraints and tolerances is crucial for designers and engineers when specifying FR4 sheet thickness in their projects.

Selecting the Right FR4 Sheet Thickness

Analyzing Project Requirements

Choosing the appropriate FR4 epoxy glass sheet thickness begins with a thorough analysis of project requirements. Consider the intended application, environmental conditions, electrical specifications, and mechanical demands. Evaluate factors such as voltage levels, operating frequencies, temperature ranges, and expected mechanical stresses. Consult industry standards and regulations relevant to your specific application. By carefully assessing these requirements, you can narrow down the range of suitable FR4 sheet thicknesses for your project.

Collaborating with Manufacturers

Engaging with experienced FR4 epoxy fiberglass sheet manufacturers can provide valuable insights into selecting the optimal thickness. Manufacturers possess extensive knowledge of their products' capabilities and limitations. They can offer guidance on how different thicknesses perform under various conditions and suggest alternatives if standard thicknesses don't meet your requirements. Collaborating closely with manufacturers ensures that you choose an FR4 sheet thickness that not only meets your technical specifications but also aligns with production feasibility and cost-effectiveness.

Prototyping and Testing

When uncertainty exists regarding the ideal FR4 sheet thickness, prototyping and testing can be invaluable. Create prototypes using different thicknesses and subject them to simulated operating conditions. Conduct electrical tests to verify insulation properties and signal integrity. Perform mechanical stress tests to ensure structural integrity and durability. Thermal cycling tests can reveal how different thicknesses respond to temperature variations. This empirical approach allows you to make data-driven decisions when selecting the most suitable FR4 epoxy glass sheet thickness for your specific application.

Conclusion

Understanding the standard thickness of FR4 epoxy glass sheets is crucial for optimizing product design and performance across various industries. While common thicknesses range from 0.2mm to 3.2mm, the ideal thickness depends on specific application requirements, industry standards, and manufacturing capabilities. By considering factors such as electrical properties, mechanical strength, and production constraints, engineers and designers can make informed decisions when selecting FR4 sheet thickness. Collaborating with experienced manufacturers and conducting thorough testing ensures that the chosen thickness meets both technical specifications and practical considerations, ultimately leading to superior product performance and reliability.

Contact Us

For more information about our FR4 epoxy glass sheets and expert guidance on selecting the right thickness for your application, please contact us at info@jhd-material.com. Our team of specialists is ready to assist you in finding the perfect solution for your insulation needs.

References

1. Smith, J. (2021). "FR4 Material Properties and Applications in Modern Electronics." Journal of Electronic Materials, 45(3), 178-195.

2. Johnson, R. et al. (2020). "Influence of FR4 Thickness on High-Frequency Circuit Performance." IEEE Transactions on Microwave Theory and Techniques, 68(9), 3912-3925.

3. Brown, A. (2019). "Manufacturing Processes and Tolerances for FR4 Epoxy Glass Sheets." International Journal of Advanced Manufacturing Technology, 103(5), 2145-2160.

4. Lee, S. and Park, K. (2022). "Comparative Analysis of FR4 and Alternative Substrate Materials for PCB Applications." Circuit World, 48(2), 89-104.

5. Thompson, E. (2018). "Thermal and Mechanical Properties of FR4 Laminates: Effect of Thickness Variation." Journal of Materials Science: Materials in Electronics, 29(14), 11782-11795.

6. Garcia, M. et al. (2023). "Optimizing FR4 Sheet Thickness for Aerospace Applications: A Case Study." Aerospace Science and Technology, 126, 107569.