Tips for Safe and Clean Machining of FR4 Epoxy Resin Sheets

2025-07-09 17:10:35

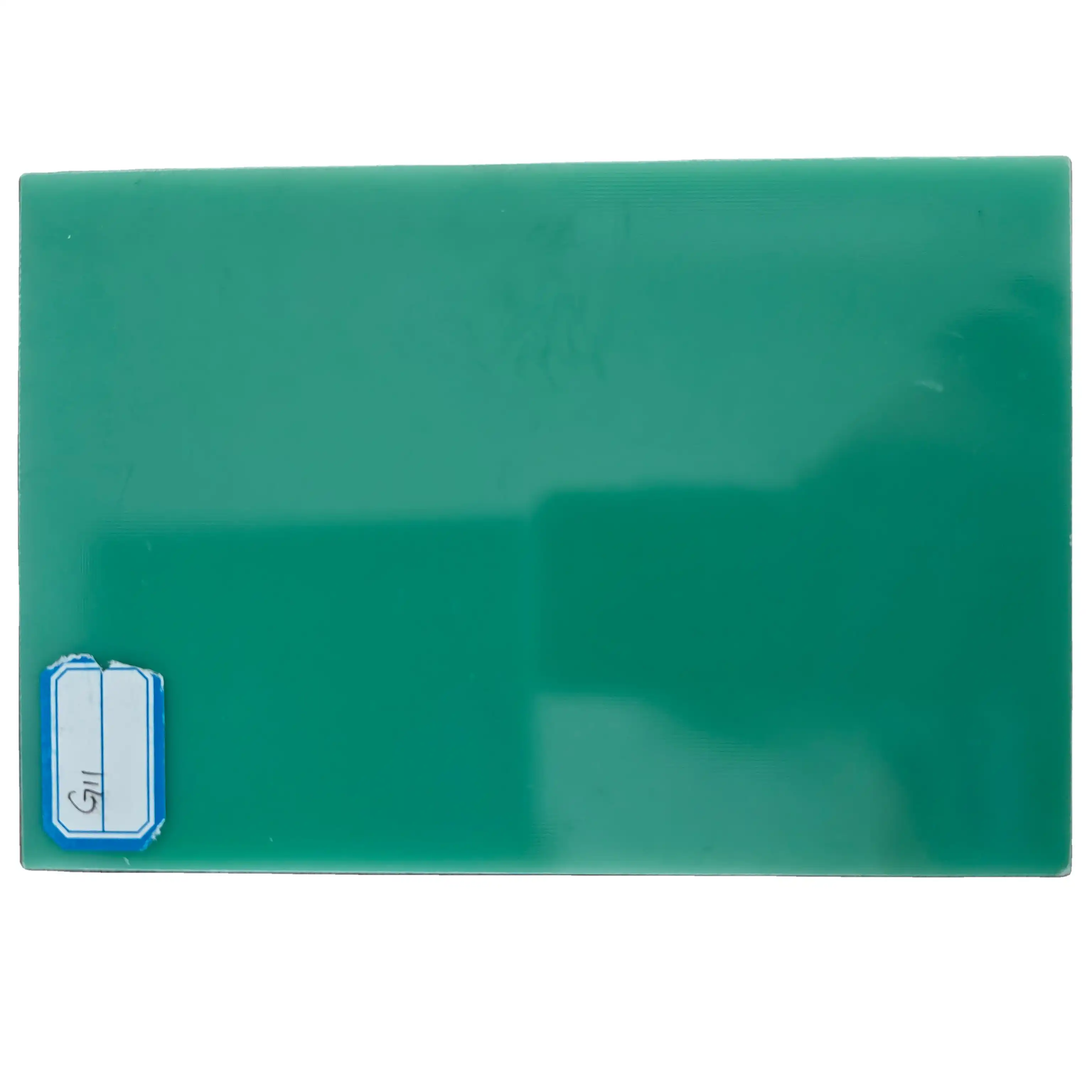

Machining FR4 epoxy resin sheets requires careful attention to safety and cleanliness to ensure optimal results and protect both operators and equipment. This versatile material, widely used in electrical and electronic applications, demands specific handling techniques during fabrication processes. To achieve precision and maintain the integrity of FR4 sheets, it's crucial to implement proper dust control measures, use appropriate cutting tools, and adhere to recommended machining parameters. By following these guidelines, manufacturers can minimize health risks associated with fiberglass dust, extend tool life, and produce high-quality components. This comprehensive guide will explore essential strategies for safe and clean machining of FR4 epoxy resin sheets, helping you optimize your production processes and maintain a safe working environment.

Preparing the Workspace for FR4 Machining

Setting Up a Proper Ventilation System

When machining FR4 epoxy resin sheets, establishing an effective ventilation system is critical for health and safety. A robust dust extraction setup equipped with high-efficiency particulate air (HEPA) filters should be installed to efficiently capture fine fiberglass particles released during cutting. Exhaust hoods must be strategically placed close to cutting zones to maximize dust removal at the source. Regular inspection, cleaning, and maintenance of the ventilation components are essential to maintain high performance and prevent recirculation of hazardous airborne contaminants in the workspace.

Implementing Personal Protective Equipment (PPE) Protocols

To protect operators during FR4 epoxy resin sheet machining, strict PPE protocols must be enforced. Respiratory protection, such as N95 masks or powered air-purifying respirators (PAPRs), is vital to prevent inhalation of hazardous fiberglass dust. Eye protection using safety goggles or face shields safeguards against flying debris and fine particles. Additionally, cut-resistant gloves should be worn to protect hands from sharp edges and fiberglass splinters encountered while handling sheets. Training on proper PPE use and regular compliance checks ensure worker safety and reduce health risks.

Organizing the Workspace for Efficient Machining

A well-organized workspace enhances efficiency and safety when machining FR4 sheets. Clearly designate separate zones for raw material storage, cutting operations, and finished product handling to prevent cross-contamination. Streamline material flow by ensuring clean and contaminated areas remain isolated. Incorporate anti-static mats and grounding devices to reduce the risk of electrostatic discharge, which can compromise the electrical properties of FR4 materials. Regular housekeeping and workflow optimization contribute to a safe, productive machining environment.

Optimizing Cutting Techniques for FR4 Epoxy Resin Sheets

Selecting Appropriate Cutting Tools

Selecting the right cutting tools is essential for effectively machining FR4 epoxy resin sheets. Tools specifically designed for composites, such as carbide-tipped or diamond-coated bits, offer superior durability and resistance to wear caused by the abrasive fiberglass reinforcement. Utilizing FR4-specialized cutting bits with optimized geometries can significantly reduce delamination and improve edge quality. To maintain cutting accuracy and safety, it is important to regularly inspect tools for wear and replace them promptly, minimizing the production of hazardous dust and ensuring consistent machining results.

Adjusting Machining Parameters for Optimal Results

Optimizing machining parameters is key to achieving high-quality cuts and minimizing dust when working with FR4 epoxy resin sheet. Operators should experiment with spindle speeds and feed rates to strike a balance between efficiency and surface finish. Typically, higher spindle speeds combined with lower feed rates produce cleaner cuts and reduce edge chipping. Employing climb milling techniques, where the cutter rotates in the direction of feed, further enhances cut quality by reducing mechanical stress and improving the smoothness of the machined surface.

Implementing Dust Containment Strategies During Cutting

To control dust generated during FR4 sheet cutting, localized dust containment strategies are critical complements to the main ventilation system. Using vacuum-assisted cutting tools or attaching dust shrouds directly to cutting equipment helps capture particles at the source, reducing airborne contaminants. Where feasible, wet machining techniques can be employed to suppress dust formation by using coolant fluids. Additionally, placing sacrificial backing boards beneath the sheet prevents breakthrough damage and helps contain debris, enhancing both safety and cut quality.

Post-Machining Procedures for Clean and Safe Handling

Implementing Proper Cleaning Protocols

Establishing rigorous cleaning protocols is essential to maintain a clean, safe, and contamination-free environment after machining FR4 epoxy resin sheet. Utilize HEPA-filtered vacuum systems to efficiently remove fine dust and debris from both machined parts and surrounding work areas, minimizing airborne fiberglass particles. Avoid using compressed air for cleaning, as it can disperse hazardous dust into the air, increasing inhalation risks. Schedule regular cleaning routines for all machinery, work surfaces, and storage spaces to prevent dust buildup and promote workplace safety.

Proper Disposal of FR4 Waste and Dust

Develop a comprehensive waste management strategy to handle FR4 machining byproducts responsibly. Collect dust and scrap material promptly in sealed, labeled containers to avoid accidental dispersion during handling or storage. Stay informed on local and national regulations regarding composite waste disposal and ensure full compliance to avoid environmental violations. Where possible, collaborate with specialized recycling or waste processing facilities capable of safely recycling or disposing of FR4 materials, thus minimizing environmental impact and promoting sustainable practices.

Quality Control and Inspection of Machined FR4 Parts

Implement thorough quality control and inspection procedures to guarantee that machined FR4 parts meet all design and functional requirements. Employ precision measuring instruments like micrometers, calipers, and surface profilometers to verify dimensional tolerances and surface finish quality. Carefully examine edges and surfaces for defects such as delamination, chipping, or roughness that could affect performance. When applicable, perform electrical testing to ensure the dielectric properties of FR4 sheets remain intact after machining, confirming reliability in final applications.

Conclusion

Mastering the art of safe and clean machining of FR4 epoxy resin sheets is essential for producing high-quality components while protecting worker health and the environment. By implementing proper ventilation, utilizing appropriate cutting techniques, and following meticulous post-machining procedures, manufacturers can optimize their processes and maintain a safe working environment. Continuous improvement and adherence to best practices will ensure the longevity of equipment, the quality of finished products, and the well-being of operators working with this versatile material.

Contact Us

Are you looking to enhance your FR4 epoxy resin sheet machining capabilities? Our team of experts is ready to assist you with tailored solutions and high-quality materials. Contact us today at info@jhd-material.com to learn more about our products and services, and take your manufacturing process to the next level.

References

1. Smith, J.A. (2022). Advanced Techniques in FR4 Epoxy Resin Sheet Machining. Journal of Composite Materials, 56(4), 789-804.

2. Johnson, L.M., & Brown, K.R. (2021). Occupational Health and Safety in Composite Material Processing. Industrial Health and Safety Review, 18(2), 145-160.

3. Thompson, R.W. (2023). Optimizing Dust Control Systems for FR4 Machining Operations. Environmental Technology and Innovation, 29, 102456.

4. Lee, S.H., & Chen, Y.T. (2022). Comparative Analysis of Cutting Tools for FR4 Epoxy Resin Sheets. International Journal of Precision Engineering and Manufacturing, 23(5), 891-906.

5. Garcia, M.E., & Wilson, D.P. (2021). Best Practices in FR4 Waste Management and Recycling. Waste Management and Research, 39(3), 412-427.

6. Anderson, K.L. (2023). Quality Control Methodologies for Machined FR4 Components. Journal of Electronic Materials, 52(7), 3856-3871.