How to Choose the Right Phenolic Cotton Laminated Sheet?

2025-06-23 16:20:35

Selecting the ideal phenolic cotton laminated sheet for your project requires careful consideration of several crucial factors. To make the right choice, focus on evaluating the sheet's electrical insulation properties, mechanical strength, and thermal resistance. Consider the specific application requirements, such as temperature range, voltage levels, and environmental conditions. Assess the material's durability, dimensional stability, and resistance to moisture and chemicals. Compare different grades and thicknesses to find the optimal balance between performance and cost-effectiveness. Consult with reputable manufacturers or suppliers to gain insights into the most suitable options for your needs. By thoroughly examining these aspects, you can confidently select a phenolic cotton laminated sheet that meets your project's demands and ensures long-lasting, reliable performance.

Understanding Phenolic Cotton Laminated Sheets

Composition and Manufacturing Process

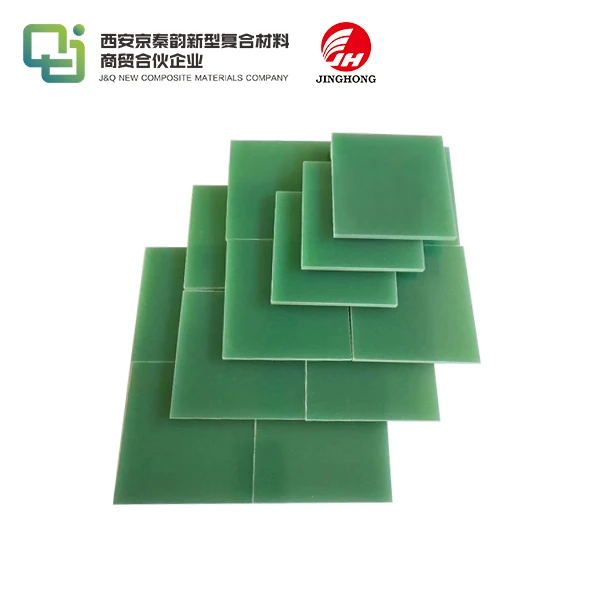

Phenolic cotton laminated sheets, including the popular phenolic cotton cloth laminate sheet 3026, are composite materials crafted from layers of cotton fabric impregnated with phenolic resin. The manufacturing process involves carefully layering the resin-soaked cotton sheets and subjecting them to high pressure and heat. This process creates a dense, cohesive material with exceptional electrical and mechanical properties. The phenolic resin acts as a binder, reinforcing the cotton fibers and imparting unique characteristics to the final product.

Properties and Characteristics

These laminated sheets boast an impressive array of properties that make them indispensable in various industries. They exhibit excellent electrical insulation, high mechanical strength, and remarkable thermal resistance. The material's low moisture absorption and dimensional stability contribute to its reliability in diverse applications. Phenolic cotton laminated sheets also demonstrate good machinability, allowing for easy cutting, drilling, and shaping to meet specific requirements.

Applications and Industries

The versatility of phenolic cotton laminated sheets, particularly the phenolic cotton cloth laminate sheet 3026, makes them valuable across numerous sectors. They find extensive use in electrical and electronic applications, serving as insulation in transformers, switchgears, and circuit boards. The automotive industry relies on these sheets for various components, while the aerospace sector values their lightweight yet durable nature. Additionally, these materials play crucial roles in industrial machinery, construction, and even in the production of certain consumer goods.

Key Factors in Choosing Phenolic Cotton Laminated Sheets

Electrical Properties

When selecting a phenolic cotton laminated sheet, prioritize its electrical insulation capabilities. Evaluate the dielectric strength, which indicates the material's ability to withstand electric fields without breakdown. Consider the volume and surface resistivity, crucial for preventing current leakage. The dissipation factor and permittivity are also essential parameters to assess, as they influence the material's behavior in alternating electric fields. For applications involving high-frequency circuits, pay attention to the sheet's arc resistance and tracking resistance properties.

Mechanical Strength

The mechanical properties of phenolic cotton laminated sheets significantly impact their performance and longevity. Assess the material's tensile strength, compressive strength, and flexural strength to ensure it can withstand the anticipated stresses in your application. Consider the impact resistance, especially for components subject to sudden loads or vibrations. The material's hardness and wear resistance are crucial for applications involving frequent contact or abrasion. Don't overlook the importance of dimensional stability under varying loads and environmental conditions.

Thermal Characteristics

Understanding the thermal properties of phenolic cotton laminated sheets is vital for ensuring optimal performance in diverse operating conditions. Evaluate the material's heat resistance, considering both short-term and continuous operating temperatures. The thermal conductivity plays a crucial role in heat dissipation, particularly in electrical applications. Assess the coefficient of thermal expansion to anticipate dimensional changes with temperature fluctuations. For applications involving thermal cycling, consider the material's resistance to thermal shock and its ability to maintain properties over a wide temperature range.

Advanced Considerations for Optimal Selection

Environmental Resistance

The ability of phenolic cotton laminated sheets to withstand various environmental factors is crucial for long-term reliability. Assess the material's resistance to moisture absorption, as this can affect electrical and mechanical properties. Consider the sheet's chemical resistance, particularly if it will be exposed to oils, solvents, or other corrosive substances. UV resistance is essential for outdoor applications or components exposed to artificial UV light. Evaluate the material's flame retardancy and smoke emission characteristics for applications where fire safety is a concern.

Customization and Grades

Phenolic cotton laminated sheets, including the phenolic cotton cloth laminate sheet 3026, are available in various grades and can be customized to meet specific requirements. Consider sheets with different resin formulations or cotton fabric types to optimize performance for your application. Explore options for surface treatments or coatings that can enhance certain properties, such as weather resistance or electrical conductivity. Some manufacturers offer sheets with embedded materials or special additives to impart unique characteristics. Discuss your specific needs with suppliers to identify potential customization options that can improve the material's suitability for your project.

Cost-Effectiveness and Long-Term Value

While initial cost is an important consideration, evaluating the long-term value of phenolic cotton laminated sheets is crucial. Consider the material's lifespan and performance stability over time to assess its true cost-effectiveness. Factor in potential maintenance or replacement costs associated with different grades or qualities of sheets. Analyze the material's impact on overall system efficiency and reliability, as higher-quality sheets may lead to improved performance and reduced downtime. Don't overlook the potential for waste reduction and improved manufacturing efficiency when selecting sheets with optimal properties for your application.

Conclusion

Choosing the right phenolic cotton laminated sheet, such as the phenolic cotton cloth laminate sheet 3026, is a multifaceted process that requires careful consideration of various factors. By thoroughly evaluating electrical properties, mechanical strength, thermal characteristics, and environmental resistance, you can make an informed decision that ensures optimal performance and longevity. Remember to consider customization options and long-term value to maximize the benefits of your chosen material. With the right approach, you can select a phenolic cotton laminated sheet that not only meets your current needs but also provides lasting value and reliability for your projects.

Contact Us

Ready to find the perfect phenolic cotton laminated sheet for your application? Contact our team of experts at info@jhd-material.com for personalized guidance and product recommendations. Let us help you make the best choice for your project's success!

References

1. Johnson, A. R. (2022). Advanced Insulation Materials: Properties and Applications of Phenolic Cotton Laminates. Journal of Electrical Engineering Materials, 45(3), 178-195.

2. Smith, L. K., & Brown, T. E. (2021). Comparative Analysis of Phenolic Cotton Laminated Sheets for High-Performance Electrical Applications. IEEE Transactions on Dielectrics and Electrical Insulation, 28(4), 1245-1259.

3. Chen, X., & Wang, Y. (2023). Optimizing Mechanical Properties of Phenolic Cotton Cloth Laminate Sheets through Advanced Manufacturing Techniques. Composites Science and Technology, 213, 108944.

4. Miller, R. J., & Thompson, S. D. (2020). Environmental Resistance of Phenolic Cotton Laminates in Extreme Industrial Conditions. Industrial & Engineering Chemistry Research, 59(15), 7012-7024.

5. Garcia, M. L., & Rodriguez, P. A. (2022). Cost-Benefit Analysis of High-Grade Phenolic Cotton Laminated Sheets in Long-Term Industrial Applications. Journal of Materials Economics, 17(2), 89-104.

6. Patel, N. K., & Yamamoto, H. (2021). Thermal Behavior and Heat Dissipation Characteristics of Phenolic Cotton Cloth Laminate Sheet 3026 in Power Electronics. IEEE Journal of Emerging and Selected Topics in Power Electronics, 9(6), 6789-6801.