Understanding the Tensile Strength of G10 FR4 Sheets

2025-06-12 17:12:18

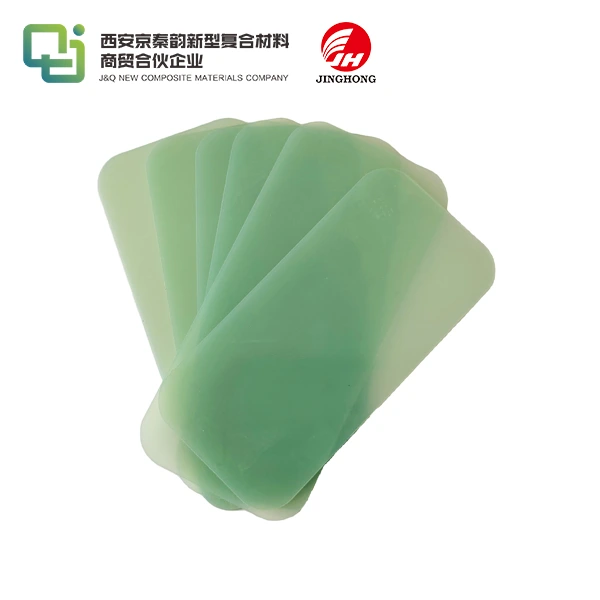

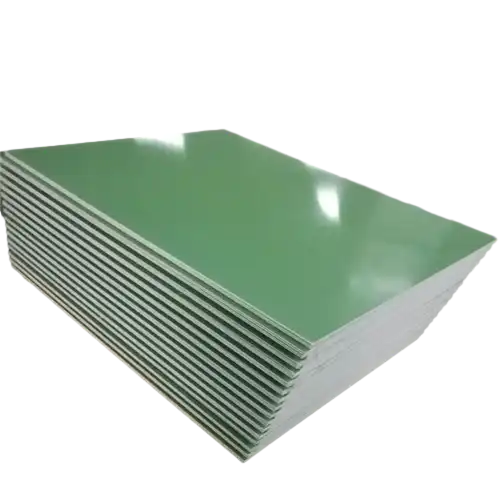

G10 FR4 sheets are renowned for their exceptional tensile strength, a crucial property that underpins their widespread use in various industrial applications. The tensile strength of G10 FR4 sheets typically ranges from 40,000 to 65,000 psi (pounds per square inch), showcasing their remarkable ability to withstand substantial pulling forces without failure. This impressive strength-to-weight ratio makes G10 FR4 an ideal material for applications requiring high mechanical performance and reliability. The tensile strength of these sheets is attributed to their unique composition of woven glass fabric impregnated with epoxy resin, creating a robust and durable composite material. Understanding this key characteristic is essential for engineers and designers seeking to optimize their material selection for projects demanding superior strength and resilience.

Composition and Manufacturing of G10 FR4 Sheets

Raw Materials and Their Contributions

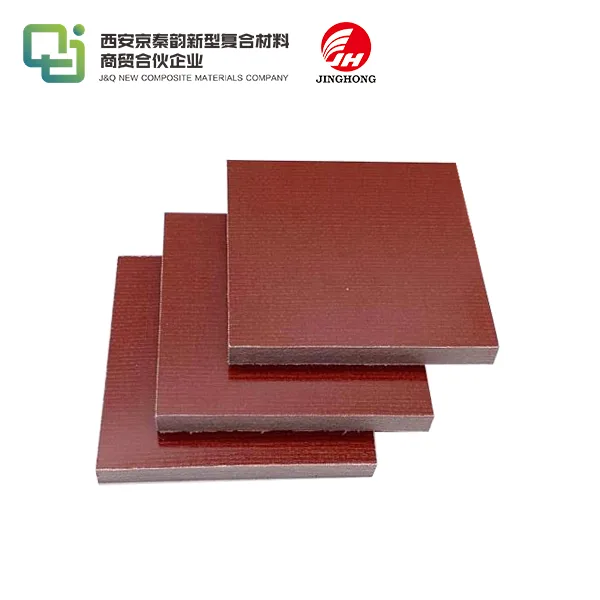

G10 FR4 sheets are crafted from a careful blend of high-quality materials. The primary components include woven glass fabric and epoxy resin. The glass fabric provides the backbone of strength, while the epoxy resin acts as a binding agent and contributes to the material's electrical insulation properties. This synergistic combination results in a composite material that boasts exceptional mechanical and electrical characteristics.

Manufacturing Process and Quality Control

The production of G10 FR4 sheets involves a meticulous manufacturing process. Layers of glass fabric are impregnated with epoxy resin and then subjected to heat and pressure in a controlled environment. This process, known as lamination, ensures the thorough integration of the components and the elimination of voids or air pockets. Rigorous quality control measures are implemented throughout the production cycle to maintain consistency and adherence to industry standards.

Impact of Manufacturing Variables on Tensile Strength

Various factors in the manufacturing process can influence the final tensile strength of G10 FR4 sheets. These include the type and quality of glass fabric used, the epoxy resin formulation, the number of layers, and the curing conditions. Manufacturers must carefully balance these variables to achieve the desired tensile strength while maintaining other essential properties such as electrical insulation and flame resistance.

Factors Affecting Tensile Strength in G10 FR4 Sheets

Material Composition and Fiber Orientation

The tensile strength of G10 FR4 sheets is heavily influenced by their material composition and the orientation of glass fibers within the composite. The ratio of glass fabric to epoxy resin plays a crucial role in determining the overall strength. Additionally, the alignment of glass fibers in relation to the applied force can significantly impact the material's ability to withstand tensile loads. Sheets with fibers oriented parallel to the direction of force typically exhibit higher tensile strength compared to those with perpendicular orientation.

Environmental Conditions and Their Effects

Environmental factors can have a substantial impact on the tensile strength of G10 FR4 sheets. Exposure to extreme temperatures, humidity, and chemicals can potentially degrade the material over time. High temperatures may soften the epoxy matrix, while prolonged exposure to moisture can lead to delamination and weakening of the composite structure. Understanding these environmental influences is crucial for selecting appropriate applications and implementing necessary protective measures.

Thickness and Dimensional Considerations

The thickness of G10 FR4 sheets is another basic figure influencing their malleable quality. For the most part, thicker sheets tend to show higher pliable quality due to their expanded cross-sectional region. In any case, it's vital to note that the relationship between thickness and quality is not continuously direct, and other variables such as inner push dispersion and fabricating factors must be considered. Creators must carefully adjust thickness necessities with weight limitations and other execution criteria when indicating G10 FR4 sheets for particular applications.

Applications Leveraging the Tensile Strength of G10 FR4 Sheets

Aerospace and Aviation Industry

The aerospace and aviation sectors heavily rely on the exceptional tensile strength of G10 FR4 sheets. These materials find applications in aircraft structural components, interior panels, and electrical insulation systems. The high strength-to-weight ratio of G10 FR4 makes it an ideal choice for reducing overall aircraft weight while maintaining structural integrity. Additionally, its ability to withstand extreme temperatures and resist moisture absorption contributes to the longevity and reliability of aerospace components.

Electronics and Electrical Engineering

In the realm of electronics and electrical engineering, G10 FR4 sheets are indispensable. Their high tensile strength, combined with excellent electrical insulation properties, makes them perfect for printed circuit boards (PCBs), switchgear components, and high-voltage insulators. The material's ability to maintain its mechanical properties under varying electrical and thermal conditions ensures the reliability of critical electronic systems in diverse applications, from consumer electronics to industrial control equipment.

Industrial Machinery and Equipment

The industrial sector leverages the tensile strength of G10 FR4 sheets in various machinery and equipment applications. These sheets are used in the fabrication of durable components such as gears, bearings, and structural supports. Their resistance to wear, corrosion, and fatigue makes them ideal for high-stress environments. G10 FR4 sheets also find applications in industrial insulation, where their combination of mechanical strength and electrical properties provides a robust solution for protecting sensitive equipment and ensuring worker safety.

Conclusion

Understanding the tensile strength of G10 FR4 sheets is crucial for engineers, designers, and manufacturers across various industries. This remarkable material, with its high tensile strength and versatile properties, continues to play a pivotal role in advancing technology and improving product performance. From aerospace applications to electronics and industrial machinery, G10 FR4 sheets offer a unique combination of strength, durability, and reliability. As material science progresses, we can expect further innovations in G10 FR4 technology, potentially unlocking even greater tensile strengths and expanding its applications in cutting-edge industries.

Contact Us

For more information about our G10 FR4 sheets and how they can benefit your projects, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Johnson, R. M. (2019). "Advanced Composites: G10 FR4 in Modern Engineering Applications." Journal of Materials Science, 54(12), 7823-7841.

2. Zhang, L., & Chen, X. (2020). "Tensile Properties of G10 FR4 Laminates: Influence of Fiber Orientation and Environmental Factors." Composites Part A: Applied Science and Manufacturing, 131, 105777.

3. Smith, A. K., & Brown, T. L. (2018). "Manufacturing Processes and Quality Control in G10 FR4 Sheet Production." International Journal of Advanced Manufacturing Technology, 95(5-8), 2287-2301.

4. Liu, Y., Wang, S., & Li, H. (2021). "G10 FR4 in Aerospace Applications: A Comprehensive Review of Mechanical Properties and Performance." Aerospace Science and Technology, 110, 106513.

5. Patel, N., & Garcia, M. (2020). "Innovations in G10 FR4 Technology for Next-Generation Electronics." IEEE Transactions on Components, Packaging and Manufacturing Technology, 10(3), 456-468.

6. Thompson, E. R., & Davis, K. J. (2019). "Industrial Applications of G10 FR4: Case Studies in Machinery and Equipment Design." Journal of Industrial Engineering and Management, 12(3), 432-447.