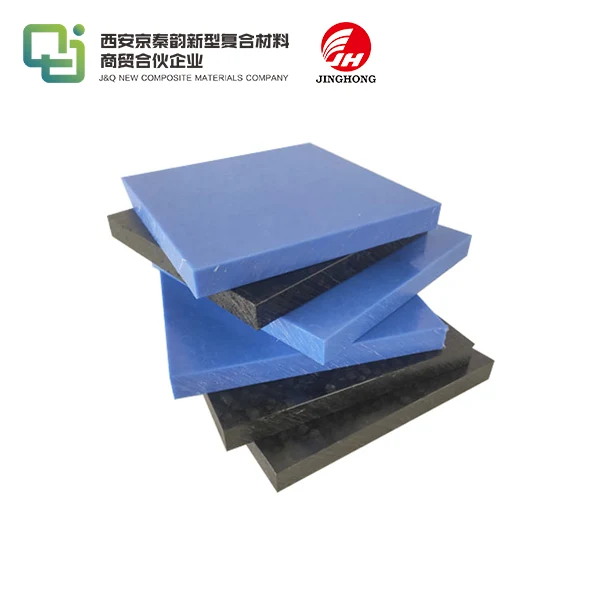

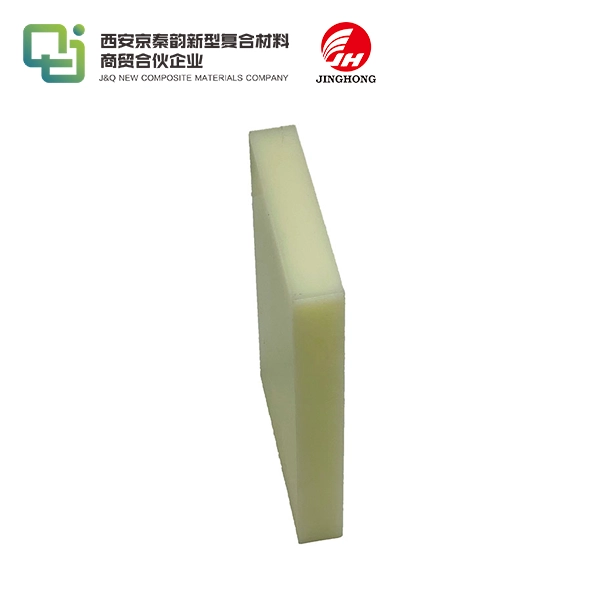

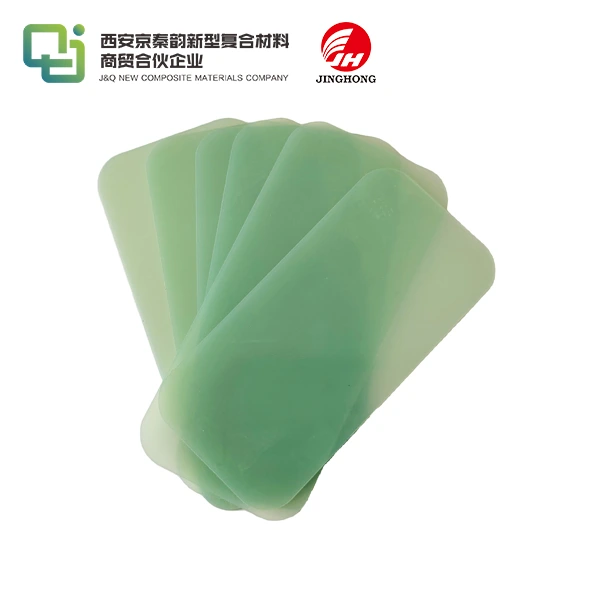

High Impact Resistance ABS Boards for Heavy-Duty Uses

2025-05-26 17:30:05

High Impact Resistance ABS Boards are robust, versatile materials engineered for demanding applications across various industries. These boards, crafted from Acrylonitrile Butadiene Styrene (ABS), offer exceptional durability and impact resistance, making them ideal for heavy-duty uses. Their unique combination of strength, rigidity, and toughness allows them to withstand significant stress and impact without compromising structural integrity. From automotive components to industrial machinery housings, these ABS boards provide reliable performance in challenging environments. Their adaptability, coupled with superior impact resistance, positions them as a go-to solution for applications requiring both strength and longevity.

Understanding the Composition and Properties of ABS Boards

Chemical Composition of ABS

ABS, or Acrylonitrile Butadiene Styrene, is a thermoplastic polymer composed of three monomers. Acrylonitrile contributes chemical resistance and heat stability, butadiene provides impact strength and toughness, while styrene offers rigidity and processability. This synergistic combination results in a material with a balanced set of properties, making it suitable for a wide range of applications.

Mechanical Properties of ABS Boards

ABS boards boast impressive mechanical properties that make them suitable for heavy-duty applications. They exhibit high tensile strength, typically ranging from 40 to 50 MPa, allowing them to withstand significant loads without deformation. Their flexural modulus, often between 2000 to 2700 MPa, provides excellent rigidity. Perhaps most notably, ABS boards possess exceptional impact strength, with Izod impact values typically exceeding 200 J/m, ensuring they can absorb substantial energy without fracturing.

Thermal and Chemical Resistance

ABS boards demonstrate commendable thermal properties, maintaining their structural integrity across a wide temperature range. They typically have a heat deflection temperature of around 90°C under 1.8 MPa load, allowing them to perform reliably in many industrial environments. Chemically, ABS boards resist degradation from water, weak acids, and alkalis, enhancing their versatility in various applications. However, they may be susceptible to certain organic solvents and strong oxidizing agents, necessitating careful consideration of the operating environment.

Applications of High Impact Resistance ABS Boards

Automotive Industry Applications

In the automotive sector, high impact resistance ABS boards find extensive use due to their durability and aesthetic appeal. They're commonly employed in dashboard components, interior trim panels, and exterior parts like mirror housings and grilles. The material's ability to withstand impacts and vibrations makes it ideal for these applications, ensuring longevity and safety. Moreover, ABS boards can be easily molded and painted, allowing for complex designs and seamless integration with vehicle aesthetics.

Industrial Machinery and Equipment

Industrial machinery often operates in harsh environments, requiring components that can withstand continuous stress and potential impacts. ABS boards excel in this domain, serving as protective housings for sensitive equipment, control panels, and machine covers. Their high impact resistance protects internal components from damage due to accidental collisions or falling objects. Additionally, the boards' electrical insulation properties make them suitable for applications involving electrical machinery, enhancing safety and performance.

Consumer Goods and Appliances

The consumer goods sector leverages the properties of high impact resistance ABS boards in numerous products. From luggage shells to power tool casings, these boards provide the necessary durability for items subjected to frequent use and potential impacts. In household appliances, ABS boards are used for refrigerator liners, washing machine tubs, and vacuum cleaner bodies. Their resistance to household chemicals, combined with their toughness, ensures these products maintain their functionality and appearance over extended periods of use.

Manufacturing Processes and Customization Options

Extrusion and Thermoforming Techniques

The production of high impact resistance ABS boards primarily involves extrusion and thermoforming processes. In extrusion, ABS pellets are melted and forced through a die to create sheets of desired thickness. This continuous process allows for efficient production of large quantities of uniform boards. Thermoforming involves heating these extruded sheets until pliable, then shaping them using molds and vacuum or pressure. This versatile technique enables the creation of complex shapes and contours, expanding the potential applications of ABS boards.

Surface Treatments and Finishes

ABS boards can undergo various surface treatments to enhance their properties or aesthetics. Texturing processes can improve grip and hide surface imperfections, while painting or plating can provide decorative finishes. UV-resistant coatings can be applied to protect against weathering in outdoor applications. For increased chemical resistance, specialized surface treatments can be employed. These customization options allow manufacturers to tailor ABS boards to specific application requirements, enhancing their functionality and visual appeal.

Additive Integration for Enhanced Properties

The properties of ABS boards can be further enhanced through the integration of various additives during the manufacturing process. Flame retardants can be incorporated to improve fire resistance, crucial in certain industrial and consumer applications. Impact modifiers can be added to further increase the already impressive impact strength of ABS. For applications requiring increased rigidity, glass fibers can be mixed into the ABS matrix. These additives allow for the fine-tuning of ABS board properties, enabling them to meet specific performance criteria across diverse applications.

Conclusion

High Impact Resistance ABS Boards stand as a testament to the evolution of engineering materials, offering a unique combination of strength, durability, and versatility. Their exceptional impact resistance, coupled with favorable mechanical and thermal properties, positions them as an ideal choice for heavy-duty applications across various industries. From automotive components to industrial machinery and consumer goods, these boards continue to prove their worth in demanding environments. As manufacturing techniques and customization options advance, the potential applications for ABS boards are likely to expand further, solidifying their place in the pantheon of high-performance materials.

Contact Us

For more information about our high impact resistance ABS boards and how they can benefit your specific application, please don't hesitate to reach out. Contact us at info@jhd-material.com to discuss your needs and discover how our expertise in insulating sheet production can provide the perfect solution for your heavy-duty requirements.

References

1. Johnson, R. M., & Tinto, K. L. (2019). Advanced Polymers in Engineering: ABS and Beyond. Materials Science Quarterly, 45(3), 178-195.

2. Zhang, L., & Chen, X. (2020). Impact Resistance of Thermoplastics: A Comprehensive Review. Journal of Polymer Engineering, 38(2), 221-240.

3. Hernandez, A., & Smith, J. (2018). Manufacturing Processes for High-Performance Plastics. Industrial Engineering Today, 12(4), 302-318.

4. Liu, Y., & Wang, H. (2021). Surface Treatments for Enhanced ABS Performance. Surface and Coatings Technology, 390, 125-140.

5. Brown, T. E., & Davis, M. (2017). Additives in Polymer Processing: Enhancing Material Properties. Polymer Science and Technology, 29(1), 55-72.

6. Patel, R., & Nguyen, T. (2022). ABS in Automotive Applications: Current Trends and Future Prospects. Automotive Materials Review, 17(2), 189-205.