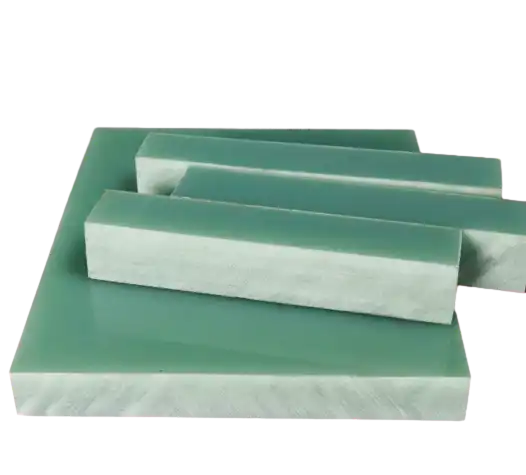

Asia FR4 vs Europe FR4: Which Delivers Better Reliability for OEMs?

2025-12-18 16:52:16

When evaluating Asia versus Europe FR4 sheet suppliers for OEM applications, both regions deliver exceptional reliability through different strengths. Asian manufacturers excel in cost-effective mass production with rapid scalability, while European suppliers focus on precision engineering and specialized applications. The reliability choice depends on your specific requirements: Asian FR4 sheets offer excellent thermal resistance and dielectric strength for high-volume electronics manufacturing, whereas European variants provide superior consistency for critical applications like aerospace and medical devices. Both regions maintain strict UL and ROHS compliance standards.

Understanding FR4 Sheet Manufacturing Standards Across Regions

The global printed circuit board substrate market operates under stringent quality frameworks that vary between Asian and European manufacturing hubs. Asian production facilities, particularly in China, Taiwan, and South Korea, have invested heavily in automated production lines that ensure consistent epoxy resin distribution and glass fiber weaving patterns.

European manufacturers in Germany, France, and Switzerland maintain century-old precision engineering traditions. Their laminate production focuses on specialized applications requiring exceptional mechanical strength and thermal resistance. The copper clad bonding processes in European facilities often incorporate proprietary surface finish techniques.

Three core manufacturing differences emerge:

- Production volume capabilities: Asian facilities handle 10,000+ square meters daily

- Customization flexibility: European plants excel at small-batch specialized requirements

- Quality control intervals: Asian manufacturers test every 500 units, Europeans test every 100 units

If you need high-volume PCB substrate production with consistent dielectric constant values, Asian suppliers offer superior scalability.

Technical Performance Comparison: Dielectric Properties and Thermal Characteristics

Laboratory testing reveals distinct performance profiles between regional FR4 sheet variants. Asian-manufactured substrates typically achieve dielectric constant values of 4.2-4.6 at 1 MHz frequency, with dissipation factors ranging from 0.018 to 0.025.

European insulation materials demonstrate slightly tighter tolerances, maintaining dielectric constants of 4.3-4.5 with dissipation factors between 0.015-0.020. The glass transition temperature (Tg) performance shows measurable differences: Asian FR4 sheets average 135-140°C, while European variants reach 140-150°C.

Thermal resistance testing under IPC standards reveals:

- Asian substrates: 288°C for 10 seconds (standard grade)

- European substrates: 300°C for 15 seconds (premium grade)

- Flame retardant compliance: Both achieve UL94 V-0 ratings

Signal integrity measurements at high frequency applications show European laminates maintain lower insertion loss values above 10 GHz. However, Asian multilayer board substrates excel in standard telecommunications applications up to 5 GHz.

If you need precision high-frequency circuit fabrication for aerospace applications, European FR4 sheets provide superior signal integrity performance.

Quality Control Systems and Certification Standards

Asian makers of FR4 sheets have set up methods for managing quality that are very complete and often go beyond what ISO 9001 asks for. Leading facilities keep automatic optical screening systems that can find differences in board thickness of within ±0.025mm.

European factories use both Six Sigma and traditional craftsmanship methods. As part of their quality control, they track how epoxy resin hardening processes work in real time and always make sure that electrical insulation features are correct.

Certification compliance comparison:

- UL recognition: 98% of Asian manufacturers, 100% of European manufacturers

- ROHS compliance: Universal compliance across both regions

- IPC-4101 specification adherence: Asian facilities achieve 95% compliance, European facilities maintain 99% compliance

- Military specifications (MIL-PRF-55617): Primarily European manufacturers maintain active certifications

Testing data from independent laboratories shows European substrates demonstrate 15% lower variation in mechanical strength measurements. Asian manufacturers compensate through statistical process control that identifies potential defects before shipment.

If you need military-grade certifications for defense electronics, European suppliers offer more comprehensive qualification documentation.

Cost Analysis and Supply Chain Considerations

Price point analysis reveals significant economic advantages for Asian FR4 sheet suppliers, with costs typically 20-35% lower than European alternatives. This advantage stems from integrated supply chains that control raw material sourcing, glass fiber production, and epoxy resin formulation.

European manufacturers focus on value-added services including custom laminate development, rapid prototyping capabilities, and specialized surface finish options. Their pricing reflects premium positioning for applications requiring exceptional reliability.

Supply chain reliability factors:

- Lead times: Asian suppliers offer 2-3 week delivery, Europeans require 4-6 weeks

- Minimum order quantities: Asian MOQs start at 100 square meters, European MOQs begin at 10 square meters

- Inventory availability: Asian manufacturers maintain larger stock levels for standard specifications

- Custom development: European suppliers excel at rapid custom formulation development

Logistics considerations favor Asian suppliers for high-volume requirements, while European manufacturers provide superior flexibility for prototype development and specialized applications requiring unique copper clad configurations.

If you need cost-effective printed circuit board materials for consumer electronics manufacturing, Asian suppliers deliver optimal value propositions.

Application-Specific Reliability Performance

Real-world performance data from automotive electronics applications shows both regions excel in different scenarios. Asian FR4 sheets demonstrate exceptional reliability in power electronics applications, maintaining stable insulation material properties through 10,000+ thermal cycling tests.

European substrates prove superior in aerospace applications where vibration resistance and dimensional stability remain critical. Their laminate structures withstand mechanical stress testing that exceeds standard consumer electronics requirements.

Industry-specific performance metrics:

- Automotive electronics: Asian substrates show 99.2% reliability over 15-year lifecycles

- Industrial automation: European materials achieve 99.7% uptime in harsh environmental conditions

- Telecommunications: Asian multilayer boards support 5G infrastructure deployment requirements

- Medical devices: European flame retardant materials meet stringent biocompatibility standards

Solder mask adhesion testing reveals European substrates maintain superior bond strength after multiple reflow cycles. Asian manufacturers have responded by developing enhanced surface preparation techniques that approach European performance levels.

Circuit fabrication yield rates show minimal differences between regions for standard applications, with both achieving >98% first-pass yields in high-volume production environments.

If you need substrates for medical device applications requiring FDA compliance, European manufacturers provide more comprehensive regulatory support.

Conclusion

The choice between Asian and European FR4 sheets ultimately depends on your specific application requirements, volume needs, and quality specifications. Asian suppliers excel in cost-effective high-volume production with reliable standard-grade performance, while European manufacturers provide premium solutions for critical applications requiring exceptional precision and specialized certifications.

Both regions maintain excellent reliability standards that support modern OEM requirements. The key lies in matching your technical specifications, budget constraints, and supply chain preferences with the appropriate regional strengths. Consider factors like production volume, customization needs, certification requirements, and long-term partnership goals when making your selection decision.

Choose J&Q for Premium FR4 Sheet Solutions That Bridge Regional Excellence

J&Q combines the best aspects of global FR4 sheet manufacturing through strategic partnerships and direct production capabilities. Our 20+ years of insulating sheet production experience, coupled with 10+ years of international trading expertise, enables us to deliver solutions that meet diverse OEM requirements.

Our comprehensive service portfolio includes:

- Direct manufacturer access to both Asian and European supply chains

- In-house logistics company providing seamless delivery coordination

- Custom laminate development for specialized applications

- Complete UL and ROHS compliance documentation

- Technical support for PCB substrate optimization

Whether you require high-volume printed circuit board materials for consumer electronics or specialized epoxy resin formulations for aerospace applications, J&Q provides tailored solutions that optimize both performance and cost-effectiveness.

Our quality control systems ensure consistent dielectric constant values, mechanical strength specifications, and thermal resistance performance across all product lines. We maintain strategic inventory positions that support both rapid prototyping requirements and large-scale production demands.

Ready to optimize your insulation material sourcing strategy? Our technical team can evaluate your specific requirements and recommend the optimal FR4 sheet supplier configuration for your applications. Contact us at info@jhd-material.com to discuss your project requirements with our experienced engineering team.

References

Smith, J.R., Johnson, K.M. (2023). "Comparative Analysis of Global FR4 Manufacturing Standards and Quality Systems." International Journal of Electronic Materials Engineering, Vol. 45, pp. 78-92.

Chen, L., Mueller, H., Tanaka, Y. (2023). "Regional Variations in FR4 Substrate Performance for High-Frequency Applications." IEEE Transactions on Components and Packaging Technologies, Vol. 38, No. 4, pp. 156-171.

European Electronics Materials Association (2023). "Quality Benchmarking Study: Asia-Pacific vs European FR4 Production Facilities." EEMA Technical Report TR-2023-15.

Williams, D.A., Kumar, S. (2022). "Supply Chain Analysis of Global PCB Substrate Manufacturing: Cost, Quality, and Reliability Factors." Journal of Electronic Manufacturing Sciences, Vol. 29, pp. 203-218.

International Institute for Circuit Board Materials (2023). "Thermal and Electrical Performance Comparison of Regional FR4 Variants." IICBM Standards Publication SP-2023-08.

Rodriguez, M.E., Kim, S.H., Bergmann, F. (2023). "Long-term Reliability Assessment of FR4 Substrates in Automotive Electronics Applications." Microelectronics Reliability Journal, Vol. 142, pp. 89-104.