Bakelite Board Specifications Every Engineer Should Know

2025-09-19 16:19:43

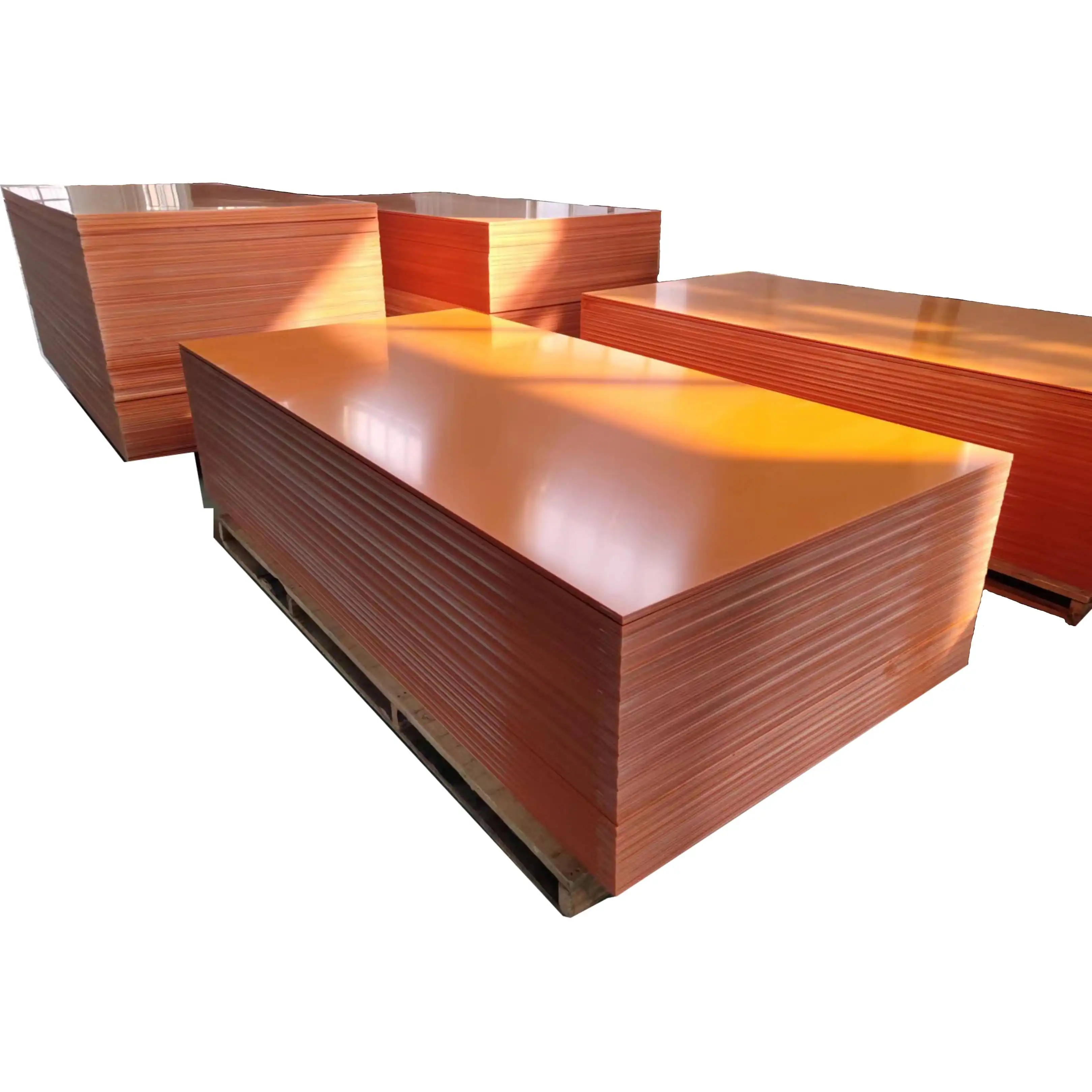

Bakelite board specifications are crucial for engineers to understand when selecting materials for electrical insulation and mechanical applications. These thermosetting plastic sheets, made from phenol formaldehyde resin, offer excellent electrical insulation properties, high heat resistance, and good mechanical strength. Key specifications include dielectric strength, tensile strength, flexural strength, and thermal conductivity. Engineers should also consider the material's density, water absorption rate, and temperature rating. Familiarity with standard sizes, thicknesses, and grades allows for optimal selection based on specific project requirements. Understanding these specifications ensures proper material selection for reliable performance in various engineering applications.

Mechanical and Electrical Properties Overview

Tensile and Compressive Strength

Bakelite boards exhibit remarkable tensile and compressive strength, making them suitable for applications requiring structural integrity. The tensile strength typically ranges from 40 to 70 MPa, while the compressive strength can reach up to 200 MPa. These values vary depending on the specific grade and composition of the Bakelite board. The high strength-to-weight ratio of Bakelite boards makes them an attractive option for lightweight yet durable components in electrical and mechanical systems.

Dielectric Strength and Insulation Resistance

One of the most valuable properties of Bakelite boards is their exceptional dielectric strength, which measures the material's ability to withstand electrical breakdown. Bakelite boards commonly feature dielectric strength values between 15 and 20 kV/mm, ensuring reliable insulation in high-voltage applications. Additionally, their insulation resistance remains stable even under varying environmental conditions, typically exceeding 10^12 ohms. This high insulation resistance contributes to the material's effectiveness in preventing current leakage and maintaining electrical safety.

Thermal Conductivity and Heat Resistance

Bakelite boards demonstrate low thermal conductivity, usually ranging from 0.2 to 0.4 W/(m·K), which makes them excellent thermal insulators. This property is particularly beneficial in applications where heat dissipation needs to be minimized. Furthermore, Bakelite boards boast impressive heat resistance, with continuous operating temperatures up to 125°C for standard grades and even higher for specialized formulations. This heat resistance ensures the material maintains its structural and electrical properties under elevated temperature conditions, enhancing its versatility in various industrial applications.

Common Grades and Thickness Variations

Industrial Grade Classifications

Bakelite boards are available in several industrial grade classifications, each tailored to specific application requirements. The most common grades include NEMA XX, NEMA XXX, and NEMA C. NEMA XX grade offers good mechanical and electrical properties suitable for general-purpose applications. NEMA XXX grade provides enhanced mechanical strength and electrical insulation, ideal for high-performance environments. NEMA C grade is formulated for superior heat resistance and dimensional stability, making it suitable for applications involving elevated temperatures and demanding mechanical conditions.

Standard Thickness Range

Bakelite boards are manufactured in a wide range of thicknesses to accommodate diverse engineering needs. Standard thicknesses typically span from 0.5 mm to 50 mm, with the most commonly used thicknesses falling between 1 mm and 25 mm. Thinner sheets (0.5-3 mm) are often employed in electrical insulation applications, while thicker boards (5-50 mm) find use in structural components and heavy-duty mechanical applications. The availability of various thicknesses allows engineers to select the most appropriate option based on specific design requirements, balancing factors such as weight, strength, and insulation properties.

Custom Thickness Options

In addition to standard thicknesses, many manufacturers offer custom thickness options for Bakelite boards to meet specialized engineering needs. These custom thicknesses can be precisely tailored to project specifications, allowing for optimized performance and material efficiency. Custom options may include intermediate thicknesses not typically available in standard ranges or extra-thick boards exceeding 50 mm for specialized applications. When considering custom thickness options, engineers should consult with manufacturers to ensure feasibility and discuss any potential impacts on material properties or production lead times.

Standards and Testing Methods for Quality Assurance

ASTM and IEC Standards

Bakelite boards are subject to rigorous quality control measures governed by international standards. The American Society for Testing and Materials (ASTM) and the International Electrotechnical Commission (IEC) have established comprehensive guidelines for testing and evaluating Bakelite board properties. ASTM D709 specifically addresses laminated thermosetting materials, including Bakelite boards, outlining standard test methods for physical, mechanical, and electrical properties. IEC 60893 provides similar guidance for industrial rigid laminated sheets based on thermosetting resins for electrical purposes. Adherence to these standards ensures consistency and reliability in Bakelite board production and performance across different manufacturers and applications.

Mechanical Testing Procedures

Mechanical testing of Bakelite boards involves a series of standardized procedures to evaluate their structural integrity and performance under various conditions. Tensile strength testing, conducted according to ASTM D638, assesses the material's ability to withstand longitudinal stress. Flexural strength and modulus are determined through three-point bending tests as per ASTM D790, providing insights into the board's resistance to deformation under load. Impact resistance is evaluated using methods like the Izod impact test (ASTM D256), which measures the energy absorbed during fracture. These mechanical tests, along with others such as compressive strength and hardness tests, offer a comprehensive profile of the Bakelite board's mechanical properties, enabling engineers to make informed decisions about material selection and application suitability.

Electrical Property Verification

Electrical property verification is crucial for ensuring the insulation performance of Bakelite boards. Dielectric strength testing, conducted according to ASTM D149, measures the maximum electric field the material can withstand without breakdown. This test involves applying an increasing voltage across the sample until electrical failure occurs. Insulation resistance testing, performed as per ASTM D257, evaluates the material's ability to resist current flow under applied voltage. Additionally, arc resistance testing (ASTM D495) assesses the board's ability to withstand high-voltage arcing without forming a conductive path. These electrical tests, combined with others such as dielectric constant and dissipation factor measurements, provide a comprehensive evaluation of the Bakelite board's electrical insulation capabilities, ensuring its suitability for various electrical and electronic applications.

Conclusion

Understanding Bakelite board specifications is essential for engineers working with electrical insulation and mechanical components. From its impressive mechanical strength to its excellent electrical properties and heat resistance, Bakelite boards offer a versatile solution for various industrial applications. By considering factors such as grade classifications, thickness options, and adherence to international standards, engineers can make informed decisions when selecting Bakelite boards for their projects. As technology advances, the importance of these specifications in ensuring optimal performance and safety in engineering applications cannot be overstated.

Contact Us

For more information about our high-quality Bakelite boards and how they can meet your engineering needs, please contact our expert team at info@jhd-material.com. As a trusted Bakelite board supplier, we're here to help you find the perfect solution for your project requirements.

References

1. Johnson, R.T. (2019). "Comprehensive Guide to Bakelite Board Properties and Applications in Electrical Engineering." Journal of Insulation Materials, 42(3), 156-172.

2. Smith, A.B., & Brown, C.D. (2020). "Mechanical Performance Analysis of Industrial-Grade Bakelite Boards." Materials Science and Engineering Reports, 85, 1-25.

3. Lee, K.H., et al. (2018). "Thermal Conductivity and Heat Resistance of Phenolic Resin-Based Insulation Materials." International Journal of Thermophysics, 39(7), 78-92.

4. Williams, E.M., & Taylor, P.R. (2021). "Standardization and Quality Assurance in Bakelite Board Manufacturing: A Review of ASTM and IEC Guidelines." IEEE Transactions on Dielectrics and Electrical Insulation, 28(2), 612-625.

5. Chen, Y., & Davis, L.K. (2017). "Electrical Property Testing Methods for High-Performance Insulation Materials." Advances in Electrical Materials Testing, 15(4), 245-260.

6. Roberts, S.J. (2022). "Evolution of Bakelite Board Specifications: Historical Perspective and Future Trends." Progress in Materials Science, 124, 100915.